Method for improving anti-tellurium corrosion performance of alloy materials for molten salt reactors and an alloy part

A technology of alloy materials and corrosion performance, which is applied in the coating process of metal materials, reactors, nuclear power generation, etc., and can solve the problems of enhanced corrosion resistance of tellurium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation of the oxide film can be realized by various existing or future technologies. At present, the techniques for obtaining surface oxide films by oxidizing easily oxidizable elements in the alloy to be treated include anodic oxidation and micro-arc oxidation. For example, aluminum alloys, magnesium alloys, titanium alloys, etc.) are effective, but are useless for other types of alloys (such as the molten salt reactor alloys involved in the present invention). For this reason, the present invention further proposes an oxide film preparation process with lower cost and simpler operation to prepare the oxide film, specifically as follows: the molten salt reactor alloy material is placed in a vacuum sealed quartz heating in the container, so that at least one active element contained in the alloy material for molten salt reactor undergoes an oxidation reaction with the hydroxyl group in the quartz to form a corresponding oxide film on the surface of the alloy ma...

Embodiment 1

[0032] Example 1: Formation of oxide film on surface of Nb-added Hastelloy N alloy and verification of tellurium corrosion resistance

[0033] Nb-added Hastelloy N alloy is a new nickel-based superalloy developed on the basis of Hastelloy N alloy to improve the corrosion resistance of tellurium. According to public reports, the composition of the alloy is (mass percentage): 6%-8% Cr, 10%-14% Mo, ≤0.2% Mn, ≤0.08% C, and the rest are Ni and unavoidable impurity elements.

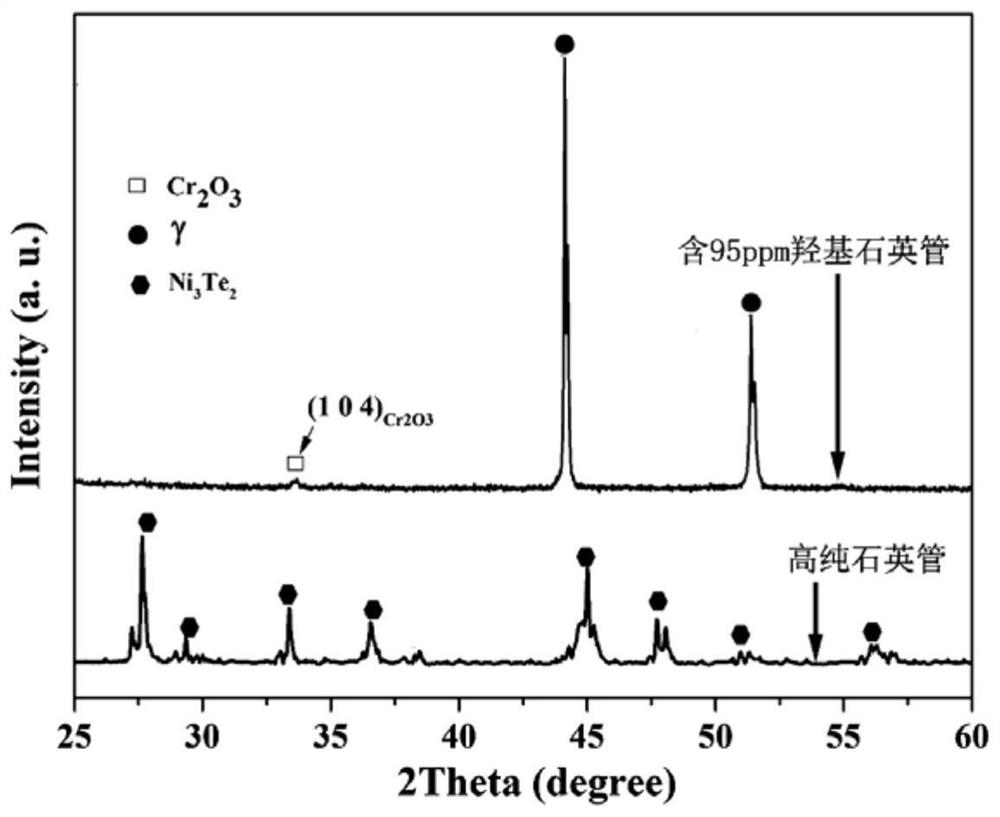

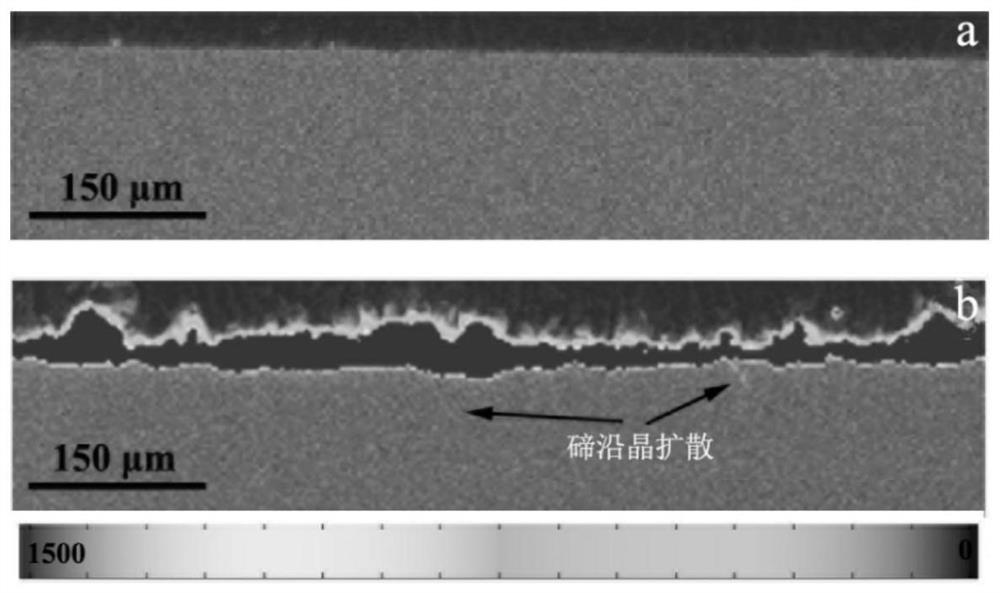

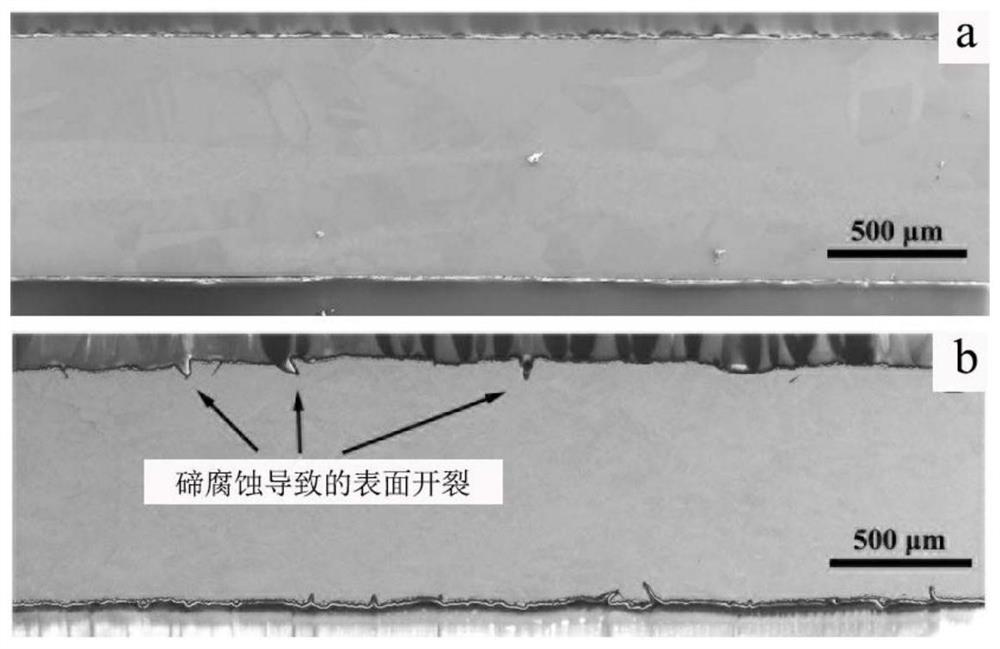

[0034] In order to form an oxide film on the surface of Nb-added Hastelloy N alloy and verify its anti-tellurium corrosion performance, the alloy and the pure tellurium block as the source of tellurium corrosion were placed in a quartz tube for heat treatment at the same time. The specific process is as follows: (1) A quartz tube (one end closed) with a length of 35 cm, an inner diameter of 2 cm, and a thickness of 2 mm is selected as the packaging material; (2) the hydroxyl content is 92 ppm measured by a Fou...

Embodiment 2

[0037] Example 2: Formation of oxide film on the surface of Ni-4Nb binary alloy and verification of its corrosion resistance to tellurium

[0038] The Ni-Nb binary alloy can be used as a functional layer to cover the surface of the existing alloy to resist tellurium corrosion. The preferred composition (mass percentage) of the alloy to exert the anti-corrosion performance of tellurium is 1-4% Nb, and the rest is Ni and unavoidable impurity elements. This implementation takes the Ni-Nb binary alloy containing 4%Nb as the implementation object.

[0039] In order to form an oxide film on the surface of the Ni-4Nb binary alloy and verify its anti-tellurium corrosion performance, the alloy and the pure tellurium block as tellurium corrosion were placed in a quartz tube for heat treatment at the same time. The specific process is as follows: (1) A quartz tube (one end closed) with a length of 35 cm, an inner diameter of 2 cm, and a thickness of 2 mm is selected as the packaging mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com