Fall prevention device for lifting scaffold

A scaffolding and lifting technology, which is applied in the field of anti-fall devices, can solve the problems of short anti-fall distance, etc., and achieve the effects of avoiding short service life, convenient processing, and reliable anti-fall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

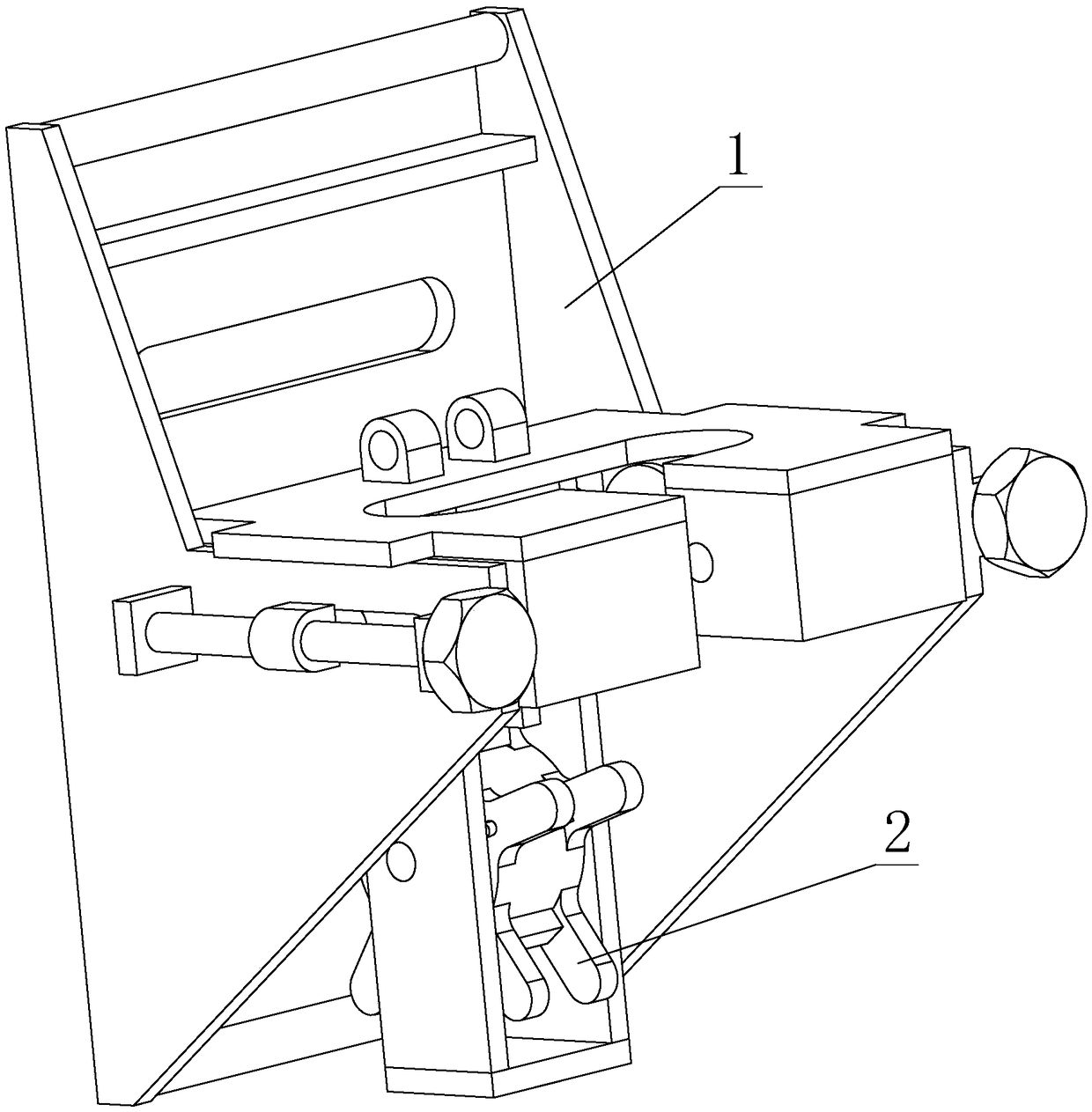

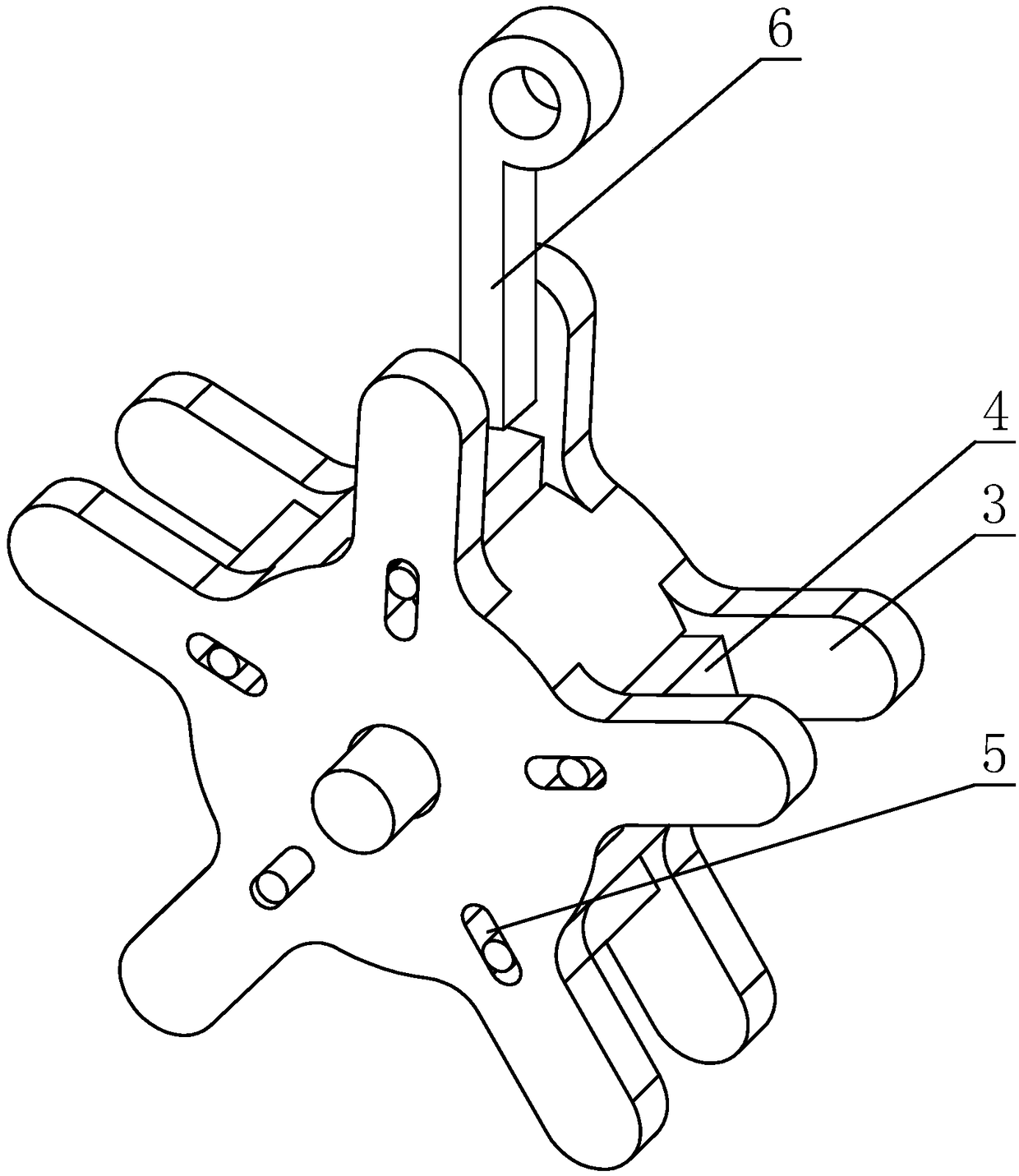

[0035] Such as figure 1 with figure 2 As shown, the anti-falling device used for lifting scaffolding includes a frame body 1 and an anti-falling wheel 2 installed on the frame body 1. The anti-falling wheel 2 is installed on the frame body 1 through a wheel shaft, and the anti-falling wheel 2 It can rotate around its own axis; the outer edge of the anti-fall wheel 2 is also provided with a plurality of radial lugs 3, which is characterized in that it also includes a slider installed on the anti-fall wheel 2 or on the radial lugs 3 4. A chute 5 is provided on the anti-falling wheel 2 or on the radial lug 3, the chute 5 is a bar-shaped groove, and the length direction of the chute 5 is along the radial direction of the anti-falling wheel 2, The slider 4 is installed on the anti-fall wheel 2 or the radial lug 3 through the chute 5, and the slider 4 can slide along the length direction of the chute 5 during the rotation of the anti-fall wheel 2;

[0036] It also includes a stop...

Embodiment 2

[0045] Such as figure 1 with figure 2 As shown, this embodiment is further limited on the basis of Embodiment 1: as a person skilled in the art, since the relative position of the radial lugs 3 needs to match the relative position of the specific upper cross bar of the scaffold, any radial The lugs 3 can constrain the scaffold to fall further rapidly. In order to make the anti-fall wheel 2 increase in speed, the stopper 6 can in time apply the rotation constraint for the anti-fall wheel 2. It is set as follows: the slide block 4 is multiple, and A plurality of sliders 4 are arranged at intervals along the circumferential direction of the anti-fall wheel 2 . This scheme is adopted to achieve the purpose of short anti-falling distance.

[0046] In order to adapt to the uniformly arranged crossbars on the track in the prior art, it is arranged that a plurality of radial lugs 3 are evenly distributed in a ring with respect to the axis of the anti-fall wheel 2 .

[0047] As a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com