High temperature flange joint deflection angle monitoring device and design method thereof

A high-temperature flange and monitoring device technology, applied in design optimization/simulation, angle/taper measurement, calculation, etc., can solve problems such as leakage, achieve the effect of improving measurement accuracy and realizing real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

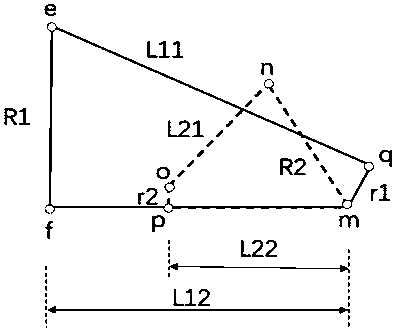

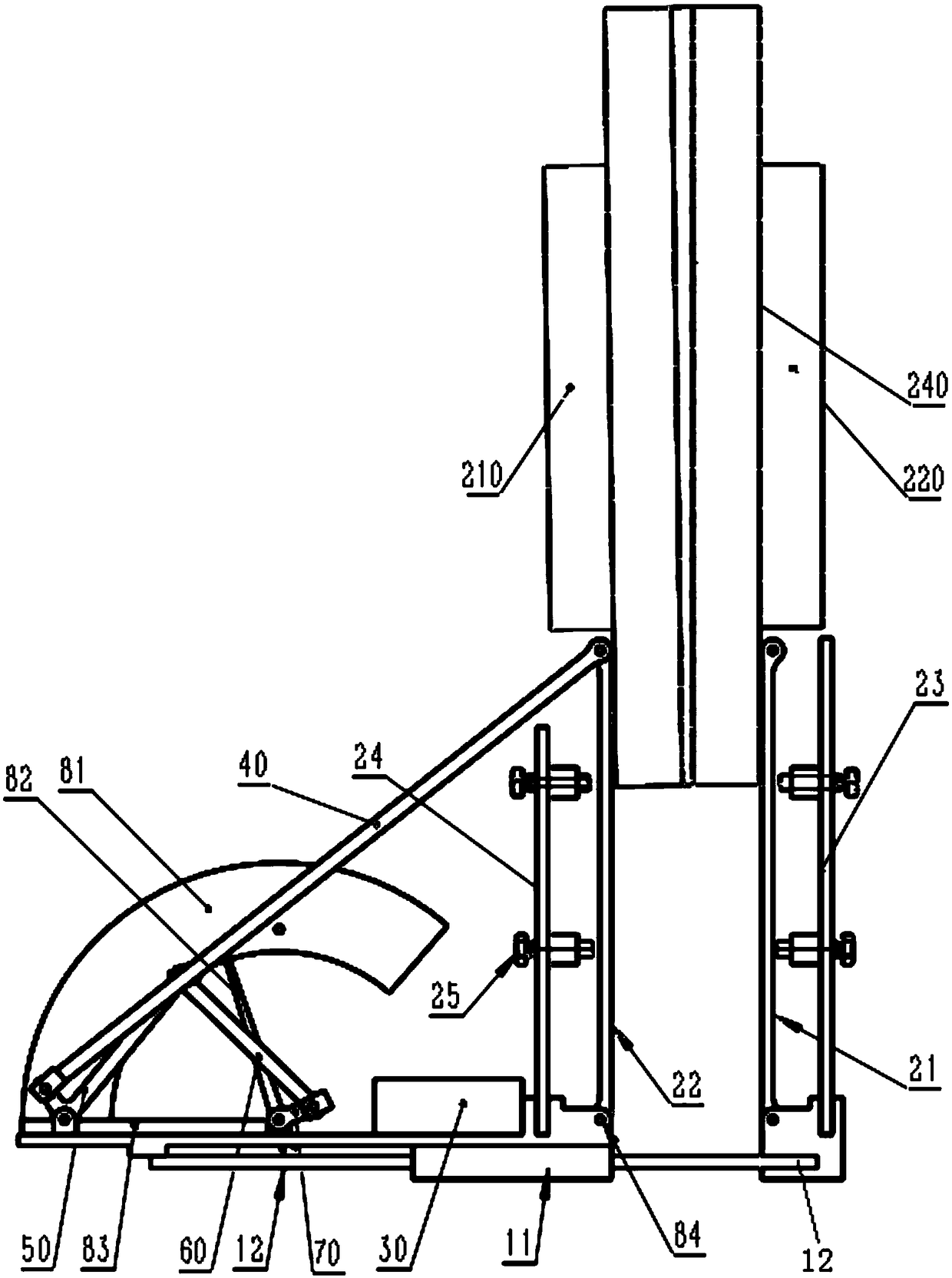

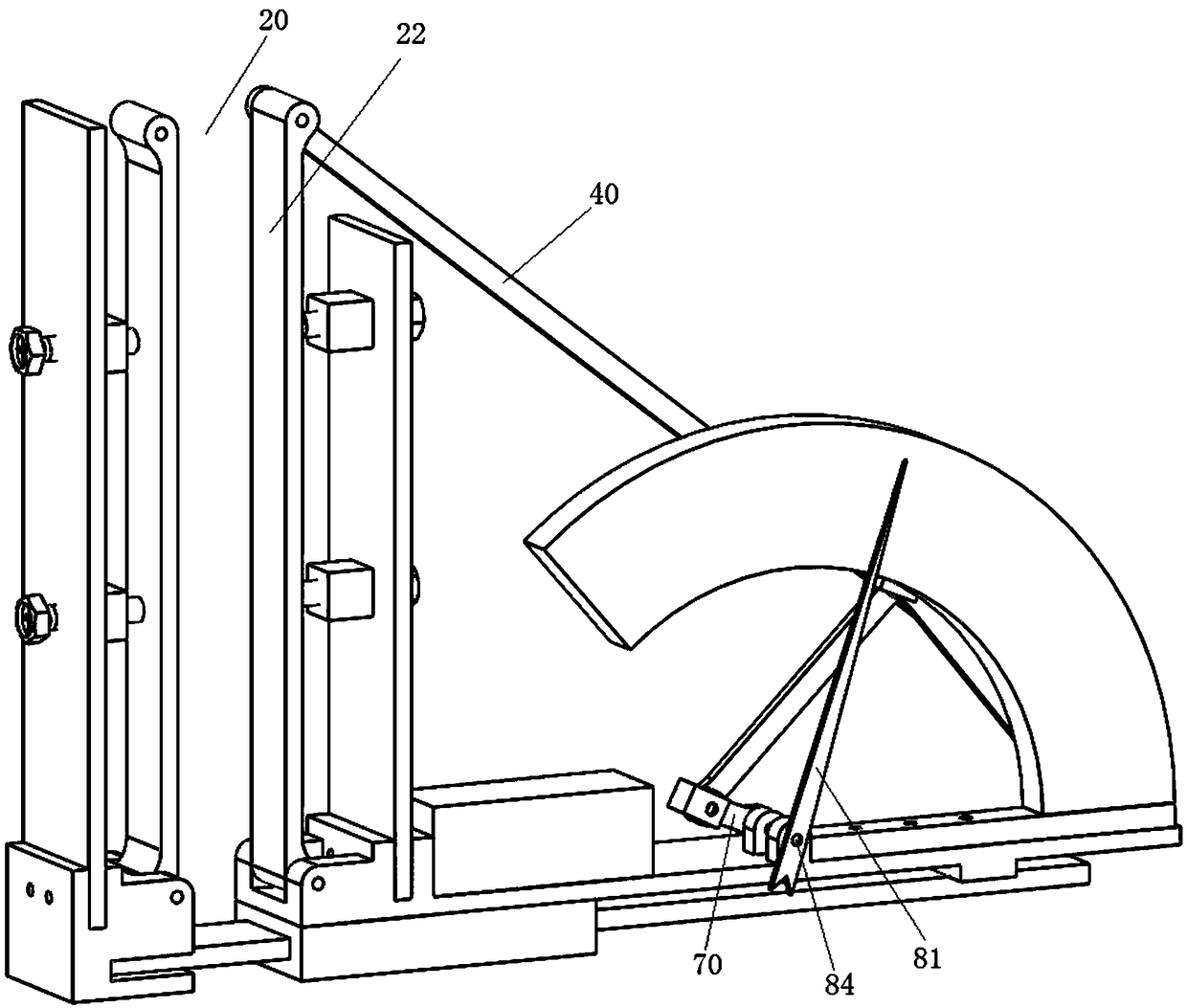

[0048] Such as Figure 1-5 As shown, it is an embodiment of the high-temperature flange joint deflection angle monitoring device of the present invention. The monitoring device includes a base, a flange fixing mechanism 20, a primary connecting rod 40, a V-shaped rod 50, a secondary connecting rod 60, and a secondary Crank 70 and angle measuring device. The monitoring object is the high temperature flange 200. The high temperature flange 200 is formed by connecting an upper flange 210 and a lower flange 220 with bolts, and a gasket 240 is used for sealing between the upper flange and the lower flange. The flange fixing mechanism 20 includes a left end splint 22 and a right end splint 21, the left end splint 22 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com