High-precision magnetic field detection and decoding circuit based on CAN bus

A CAN bus and decoding circuit technology, applied in the field of rotating magnetic field detection and decoding circuits, can solve the problems of complex peripheral circuits of analog potentiometers, oscillating application costs, brush wear systems, etc., to save circuit design costs, easy to implement, The effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Based on such a principle, the present invention designs a bipolar magnetic steel and installs it in the rudder shaft. The magnetic steel is facing the magnetic encoding chip, and the encoding chip measures the rotating magnetic field, and sends the measurement result to the main control chip through a dedicated SSC interface. MCU, the MCU completes the reception and decoding of the magnetic field to obtain the corresponding rudder shaft rotation angle; after the MCU completes the calculation, the digital signal is sent to the servo control circuit in real time through the CAN bus control module to complete the closed-loop control of the servo system.

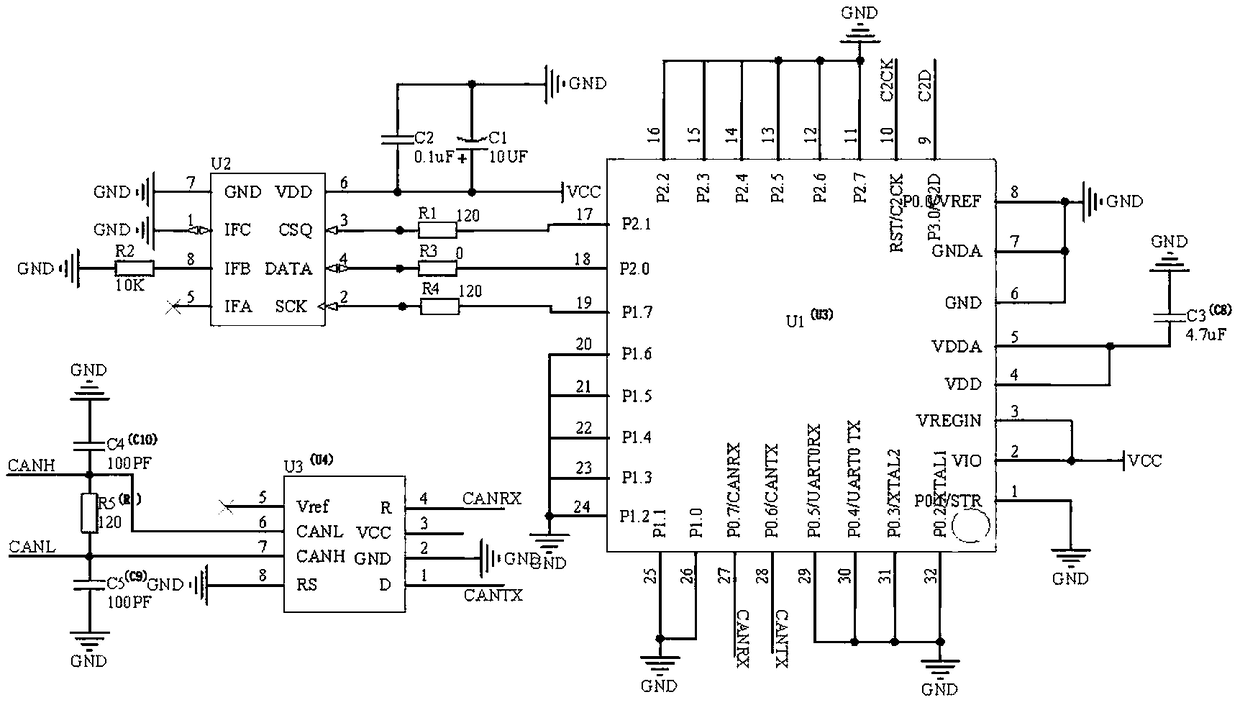

[0017] Such as figure 1 As shown, the present invention is such a circuit that indirectly measures the rotating magnetic field based on CAN bus communication, and completes high-precision magnetic field decodin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com