A non-destructive testing method for hydroxyl content in quartz glass

A quartz glass and non-destructive testing technology, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as product damage and difficult processing, and achieve the effect of simplifying the measurement steps, reducing difficulty, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] This example provides the extinction coefficient ε of hydroxyl groups in quartz glass at 1.38 μm and 2.22 μm 1.38μm , ε 2.22μm calculation method.

[0099] In this embodiment, the quartz glass is synthetic quartz glass with a thickness of 1mm.

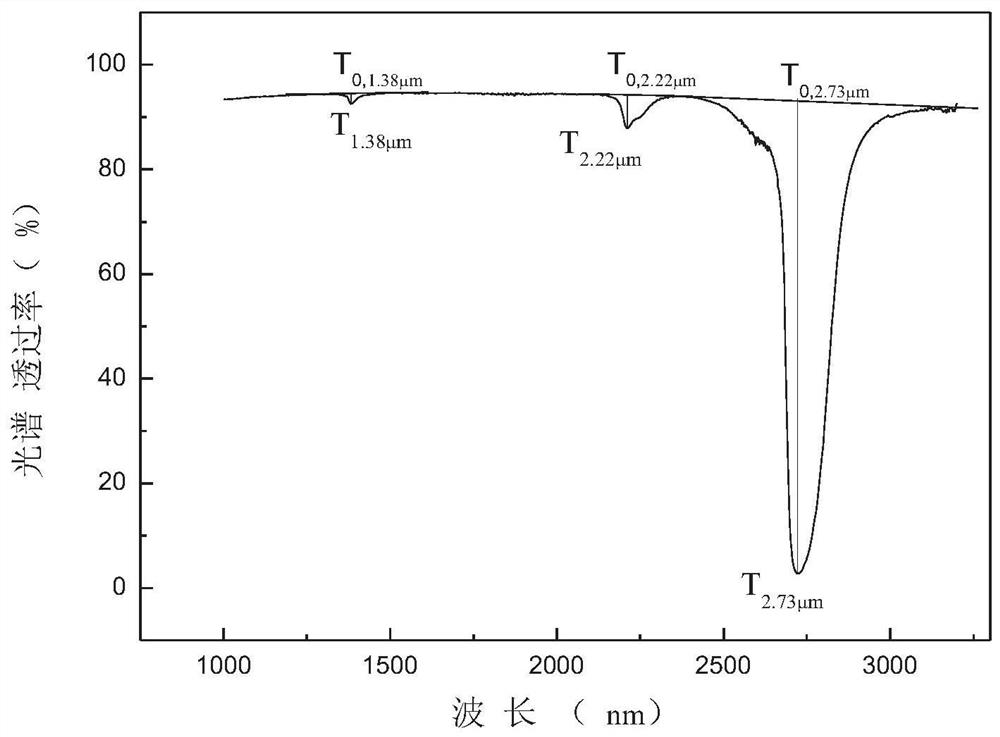

[0100] In this embodiment, the spectral transmittance curve of quartz glass in the wavelength range of 1000nm to 3200nm is as follows figure 1 shown. figure 1 The baseline spectral transmittance T at the positions of 2.73μm, 2.22μm and 1.38μm 0 See Table 1 for the absorption peak spectral transmittance T.

[0101] Table 1 figure 1 T at the positions of 2.73μm, 2.22μm and 1.38μm 0 and T

[0102]

[0103] In this embodiment, the extinction coefficient ε of the hydroxyl group in quartz glass at 2.73 μm is selected. 2.73μm Value 80.1L·mol -1 cm -1 , calculated according to the second formula, the extinction coefficient ε of the hydroxyl group in quartz glass at 1.38 μm is obtained 1.38μm 0.45Lmol -1 cm -1 ; Accordin...

Embodiment 2

[0112] This embodiment provides a non-destructive testing method for hydroxyl content in synthetic quartz glass.

[0113] The thickness of the synthetic quartz glass 1 in this embodiment is 5.25 mm.

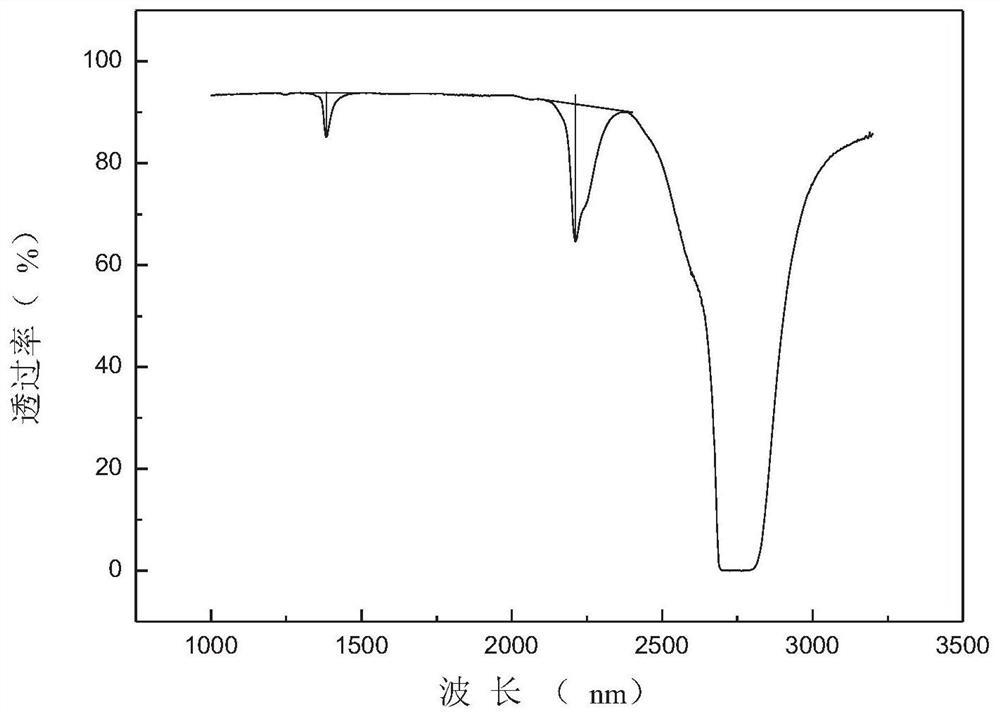

[0114] In this embodiment, the spectral transmittance curve of synthetic quartz glass 1 in the wavelength range of 1000nm to 3200nm is as follows figure 2 shown.

[0115] If the detection method of hydroxyl content in quartz glass recorded in the prior art GB / T 12442-90 is adopted, since the thickness of synthetic quartz glass 1 in this embodiment is 5.25mm, it has exceeded the thickness of artificial quartz glass specified in this standard by 0.4- 0.7mm, and, by figure 2 It can be seen that the synthetic quartz glass 1 of this embodiment cannot display the spectral peak at 2.73 μm, so the method described in GB / T12442-90 cannot be used for detection.

[0116] figure 2 The baseline spectral transmittance T at the position of 2.22μm and 1.38μm 0 And the absorption peak spe...

Embodiment 3

[0121] This embodiment provides a non-destructive testing method for hydroxyl content in synthetic quartz glass.

[0122] In this embodiment, the thickness of the synthetic quartz glass 2 is 11 mm.

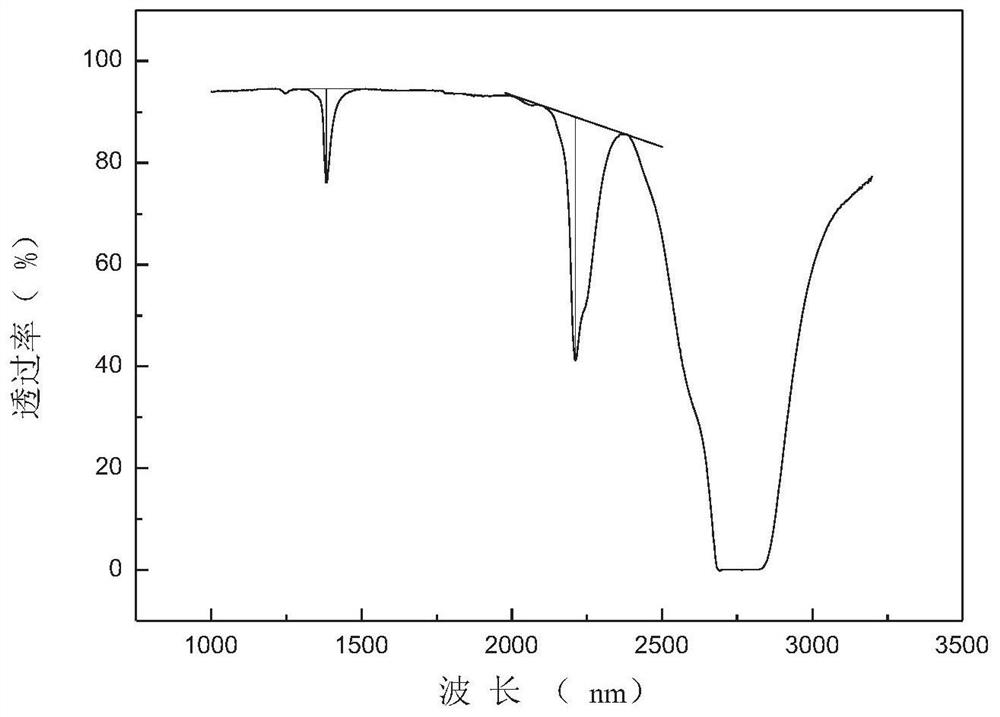

[0123] In this embodiment, the spectral transmittance curve of the synthetic quartz glass 2 in the wavelength range of 1000nm to 3200nm is as follows image 3 shown. image 3 The baseline spectral transmittance T at the position of 2.22μm and 1.38μm 0 And the absorption peak spectral transmittance T is shown in Table 3.

[0124] table 3 image 3 T at the positions of 1.38μm and 2.22μm in 0 and T

[0125]

[0126] With the extinction coefficient ε obtained in embodiment 1 2.22μm , The baseline spectral transmittance T at the position of 2.22μm 0 and the absorption peak spectral transmittance T are substituted into the first formula described, and the calculation obtains that the hydroxyl content of the synthetic quartz glass 2 in the present embodiment is 1469ppm; the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com