Non-stop wind power blade detection device

A technology of wind turbine blades and detection devices, which is applied in the field of detection systems, can solve problems such as difficult detection, difficult comprehensive detection, and accident-prone problems, and achieve the effects of improving enterprise production efficiency, improving detection efficiency, and real-time intelligent identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

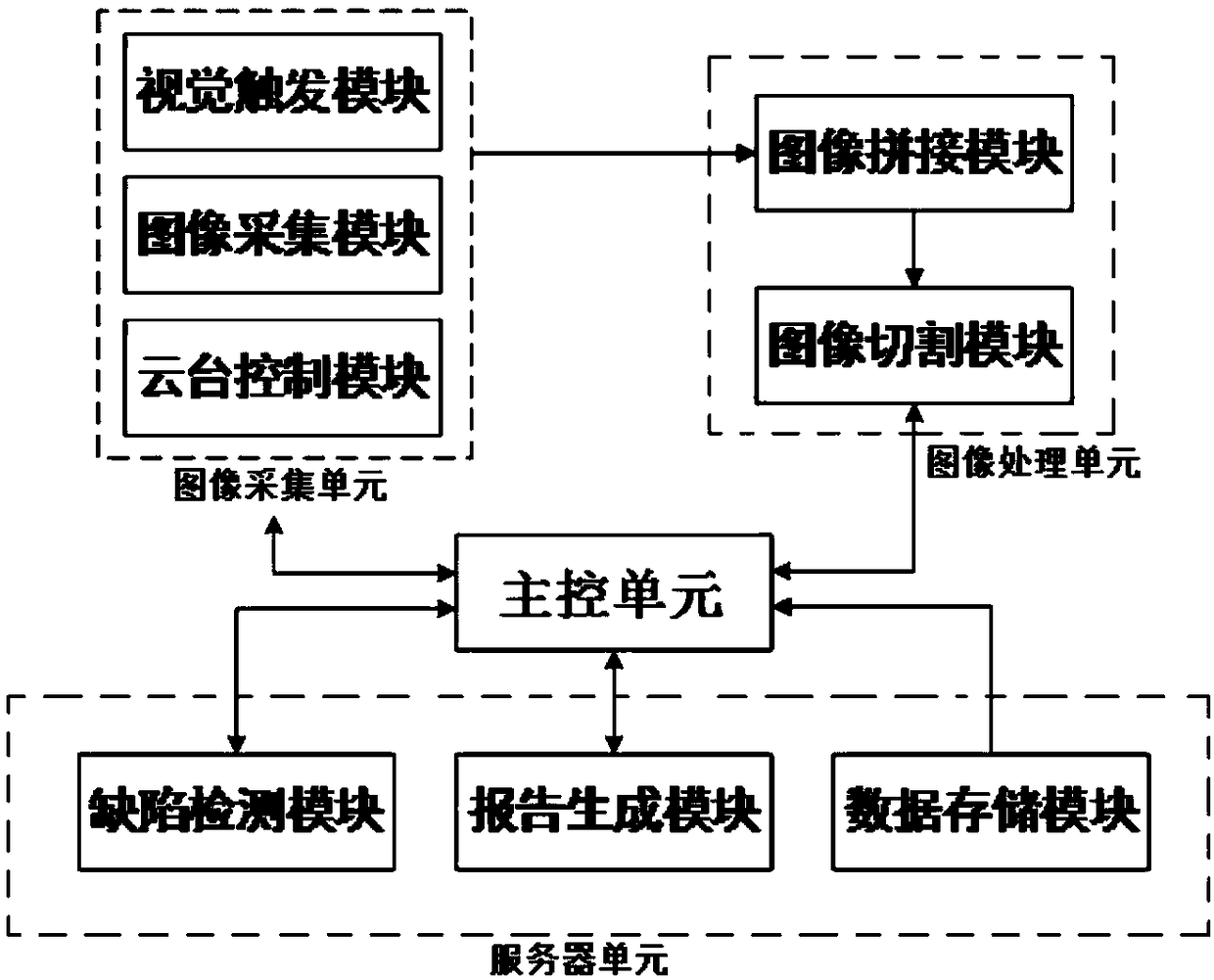

[0041] Such as figure 1 As shown, the present invention provides a non-stop wind turbine blade detection device, including:

[0042] The image acquisition unit is used for fixed-point local capture of wind power blades in operation;

[0043] an image processing unit, configured to process the wind power blade image collected by the image collection unit;

[0044] The main control unit is used to control the coordinated operation among the image acquisition unit, the image processing unit and the server unit;

[0045] a server unit, configured to process instructions sent by the main control unit;

[0046] The image acquisition unit, image processing unit and server unit are all connected to the main control unit.

[0047] The image acquisition unit includes: a visual trigger module, an image acquisition module, and a pan / tilt control module. When the wind turbine blades run within the coverage of the image acquisition module, the visual trigger module sends a control comman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com