A non-stop detection device for wind turbine blades

A wind power blade and detection device technology, applied in the field of detection systems, can solve the problems of difficult detection, difficult detection comprehensively, and great influence, and achieve the effects of improving enterprise production efficiency, improving detection efficiency, and reducing operation risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

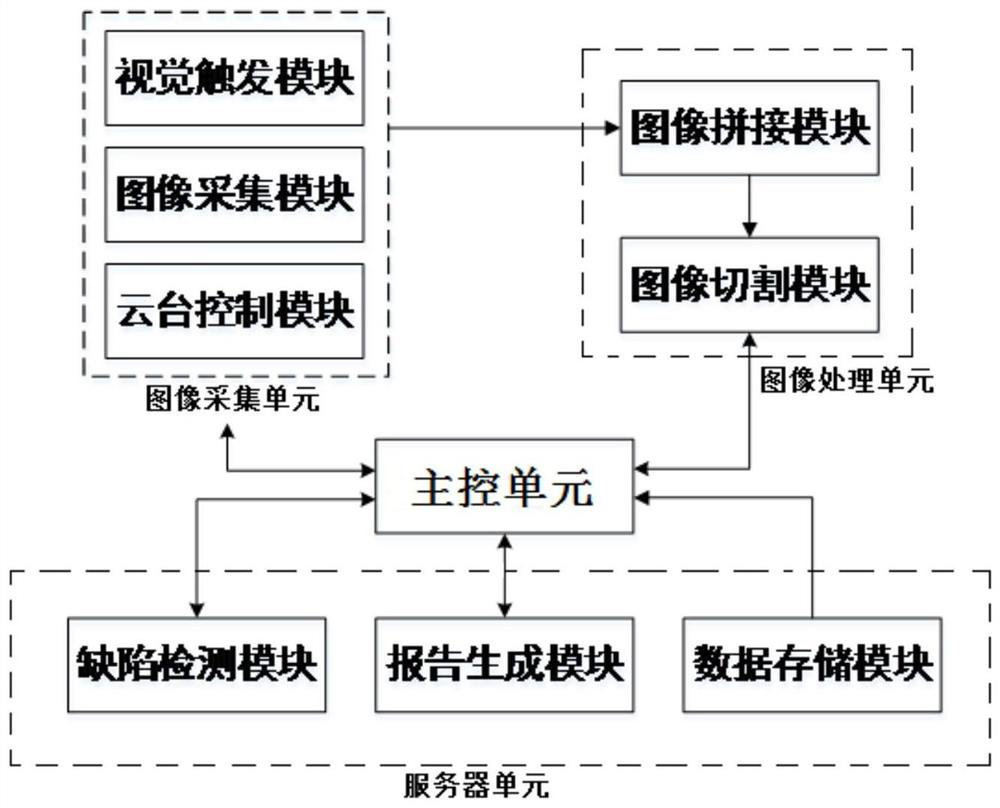

[0041] Such as figure 1 As shown, the present invention provides a non-stop wind turbine blade detection device, including:

[0042] The image acquisition unit is used for fixed-point local capture of wind power blades in operation;

[0043] an image processing unit, configured to process the wind power blade image collected by the image collection unit;

[0044] The main control unit is used to control the coordinated operation among the image acquisition unit, the image processing unit and the server unit;

[0045] a server unit, configured to process instructions sent by the main control unit;

[0046] The image acquisition unit, image processing unit and server unit are all connected to the main control unit.

[0047] The image acquisition unit includes: a visual trigger module, an image acquisition module, and a pan / tilt control module. When the wind turbine blades run within the coverage of the image acquisition module, the visual trigger module sends a control comman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com