Grain mass and heat transfer and condensation parameter detection device and method

A technology of parameter detection and heat transfer, applied in the direction of material thermal conductivity, material thermal development, material moisture content, etc., can solve the problems that the basic research of multi-field coupling lags behind the actual application and demand, and it is difficult to guide the actual application demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

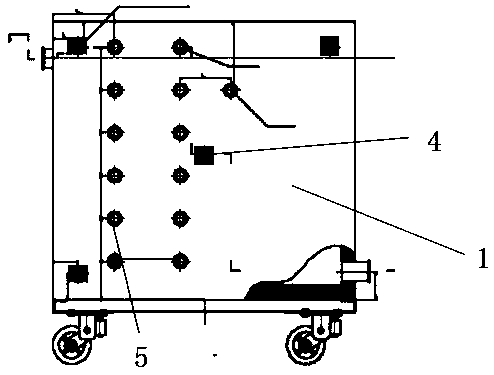

[0051] Such as figure 1 As shown in -3, a grain heat transfer detection device includes a main body of the device. The main body of the device is a cuboid simulation experiment chamber 1, and each side wall of the simulation experiment chamber 1 is a two-layer structure inside and outside (the outer layer 201 is a layer, made of polystyrene), the outer layer 201 of the front and rear side walls and the inner layer 202 of each wall respectively enclose a cavity 203 for gas circulation, the outer layer 201 of the left and right side walls and each The inner layer 202 of the wall is filled with heat insulation material, and an inner cavity 3 is formed between the inner layers of each wall; a cold source (cold air ), which is called the cold wall surface, and the side of the cold wall surface close to the outer layer 201 is provided with a 5.0cm thermal insulation material; a heat source (hot air) is connected between the inner and outer layers of the chamber wall opposite to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com