Apparatus and method for picking-up and placing reaction cup and equipment comprising apparatus

A technology of reaction cups and cup stems, which is applied in the direction of analysis, instruments, chemiluminescence/bioluminescence, etc. by making materials undergo chemical reactions, which can solve the problems of increasing equipment maintenance costs, component failure, frequent maintenance, etc., and achieve guaranteed detection Accuracy and detection efficiency, reduced maintenance costs, and the effect of avoiding empty grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment is a preferred device for picking and placing cuvettes.

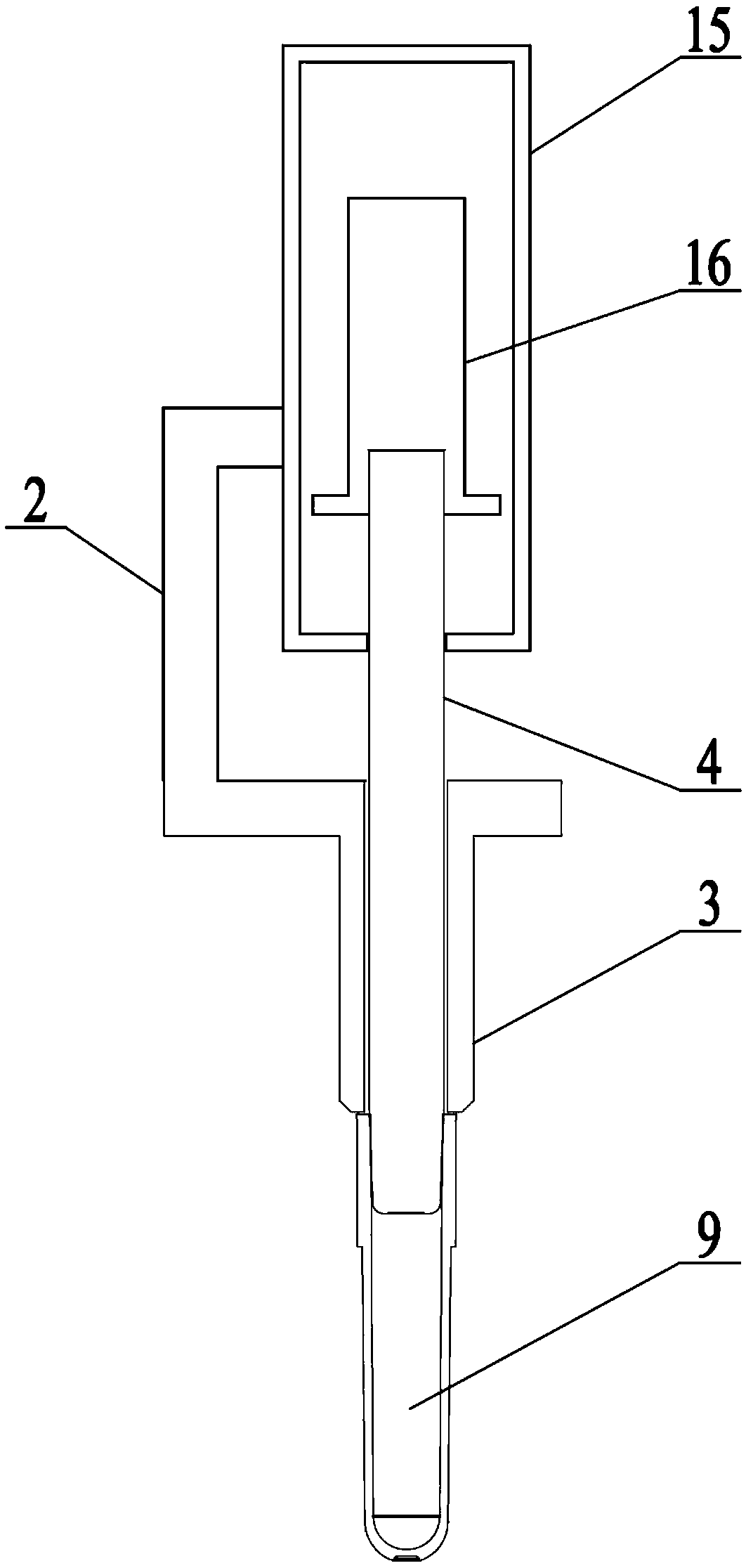

[0065] Such as figure 1 As shown, the device for picking and placing cuvettes described in this embodiment includes a pick-up mechanism, a movement mechanism, a cup removal mechanism, a drive mechanism and a housing, wherein the pick-up mechanism includes a cup-taking lever 4, and the movement mechanism includes a piston 16 , The cup removal mechanism includes a sleeve 3, and the driving mechanism includes a cylinder 15.

[0066] In this embodiment, when the cuvette 9 is picked up, the inner wall of the cuvette 9 is in contact with the outer wall of the stem 4, and is maintained by the friction force between the two. The inner diameter of the cuvette is slightly smaller than the outer diameter of the end of the stem 4. (such as small 0.1mm, 0.2mm, 0.25mm, 0.3mm, 0.4mm, etc.), and the bottom of the cup stem 4 is an inverted arc structure, which is beneficial to the upper opening of the embedded cu...

Embodiment 2

[0071] This embodiment is an optimized implementation of the device for picking up and placing cuvettes described in Embodiment 1. Its main optimization points are that different drive mechanisms and motion mechanisms are provided, and the connection mode of the cup stem and the connection of the sleeve way, as well as the use of different shell forms, and the addition of a vent hole for the cup stem, the specific improvements are as follows:

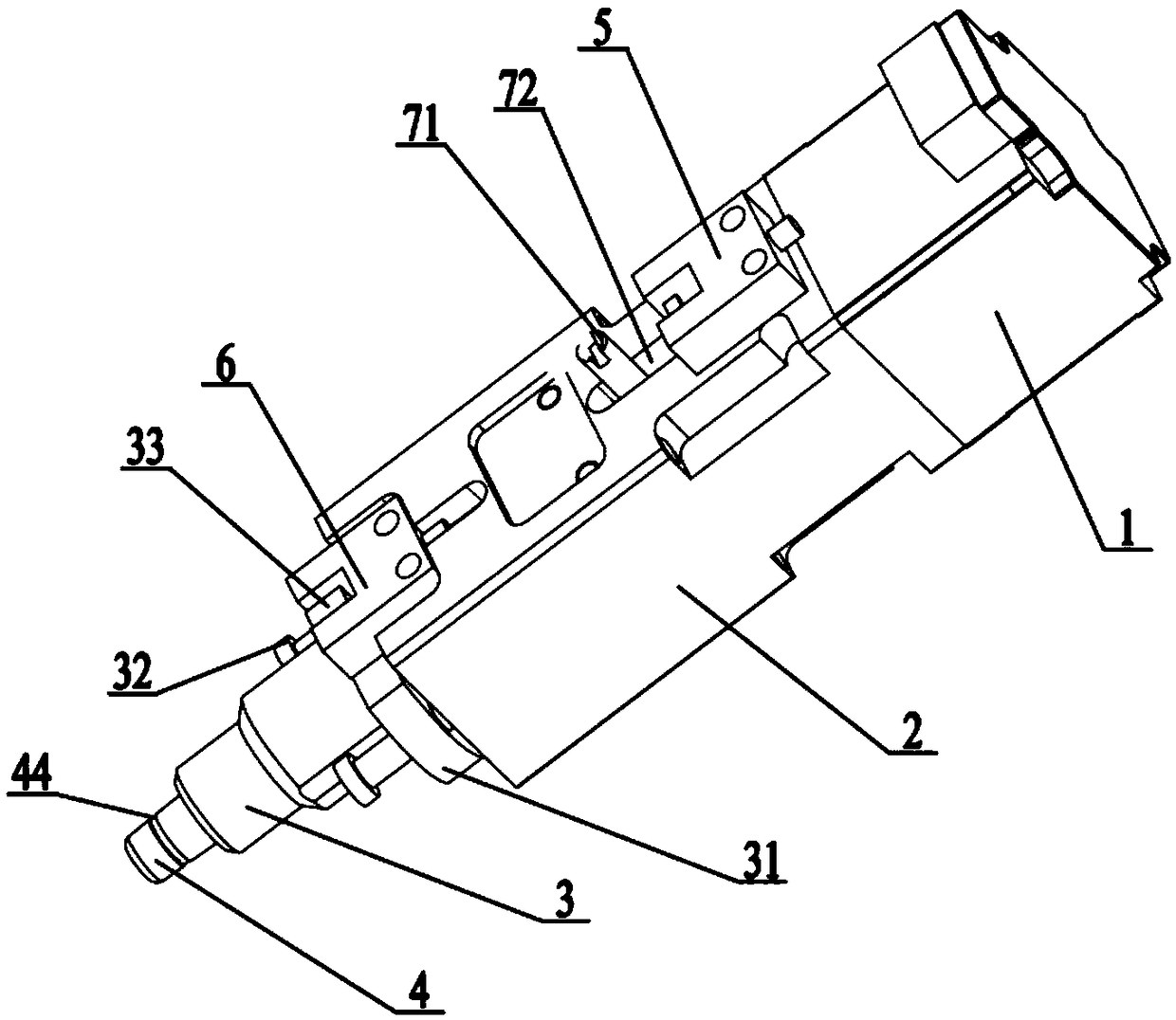

[0072] Such as Figure 2 to Figure 5 As shown, the movement mechanism in the device for picking and placing cuvettes described in this embodiment includes a nut 7 , and the driving mechanism includes a motor 1 .

[0073] In this embodiment, the cup stem 4 is integrally fixed to the bottom of the cup stem connector 41; the nut 7 is fixed to the top of the cup stem connector 41 by screw connection; the top end of the sleeve 3 is It is integrally formed on the bottom of the sleeve mounting plate 31. The bottom end of the sleeve 3 is used ...

Embodiment 3

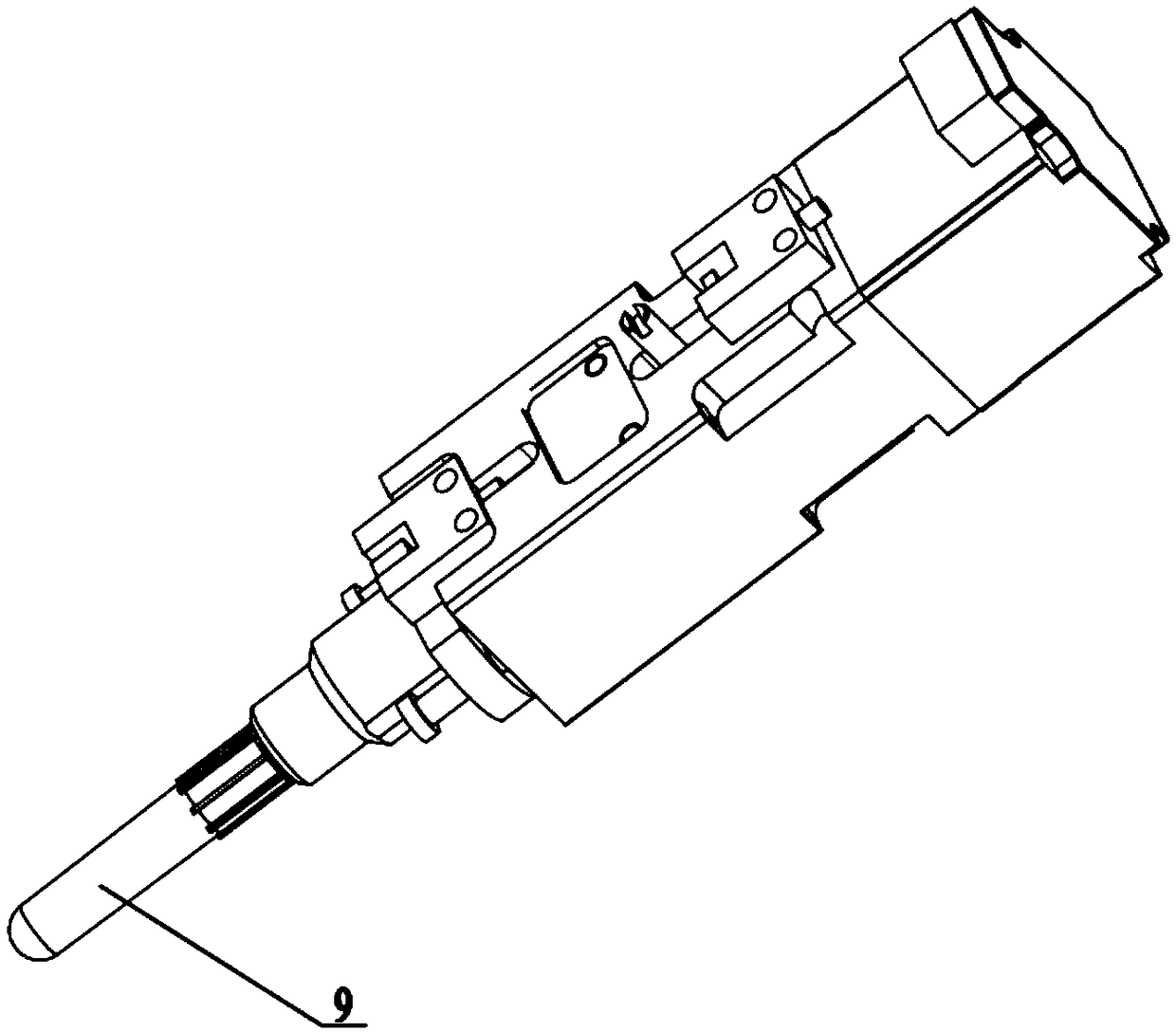

[0078] This embodiment is an optimized implementation of the device for picking and placing cuvettes described in the second embodiment. The main optimization point is to set up a detector for detecting the position of the sleeve and the nut, and adopt different forms of cuvettes and drive mechanisms, and optimize the installation form of the sleeve. The specific improvements are as follows:

[0079] In this example, if Figure 2 to Figure 5As shown, the screw rod 11 is sleeved with a screw limiting groove 12, and the screw limiting groove 12 is opened in the cup-taking rod connector 41, so as to prevent the screw rod 11 from driving the nut 7 to move downwards excessively and damage the device; and The side end of nut 7 is equipped with nut stopper bar 71, and housing 2 offers nut stopper groove 72, and nut stopper bar 71 extends through described nut stopper groove 72, and is positioned at the casing 2 of nut stopper groove 72 tops. The first sensor 5 is installed externall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com