A Vibration Moment Suppression Method for Magnetic Bearings Based on Complex Variable Finite-Dimensional Repeated Control

A technology of vibration torque and repetitive control, which is applied in the direction of electric speed/acceleration control, etc., and can solve the problems that repeated control cannot be used, the stability of the closed-loop system has a great influence, and the vibration torque suppression accuracy of the magnetic bearing system is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation steps.

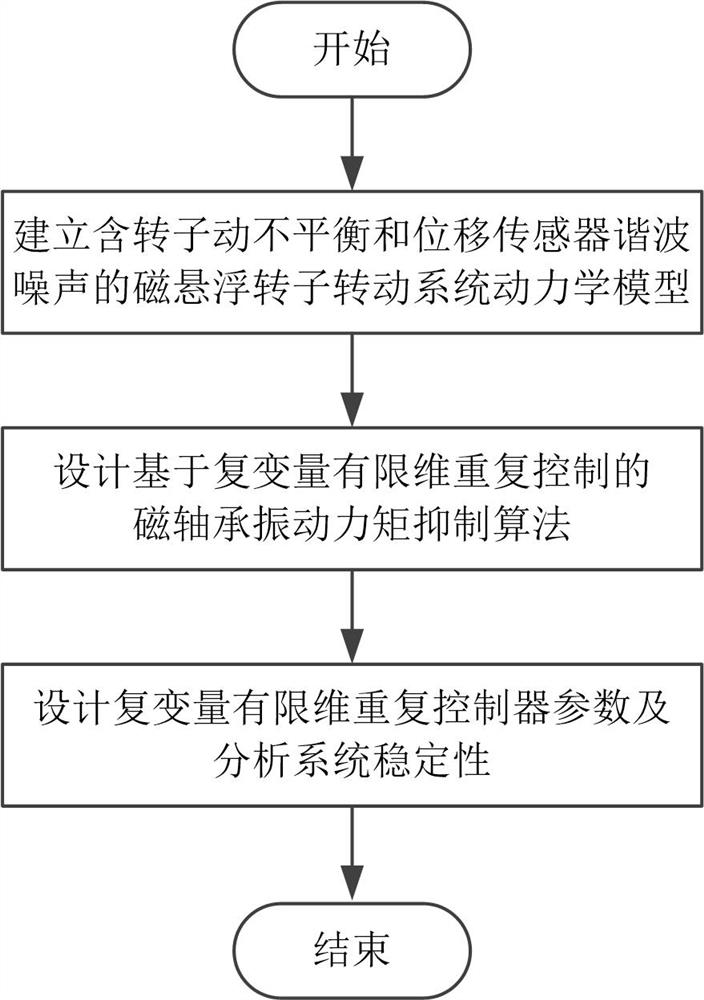

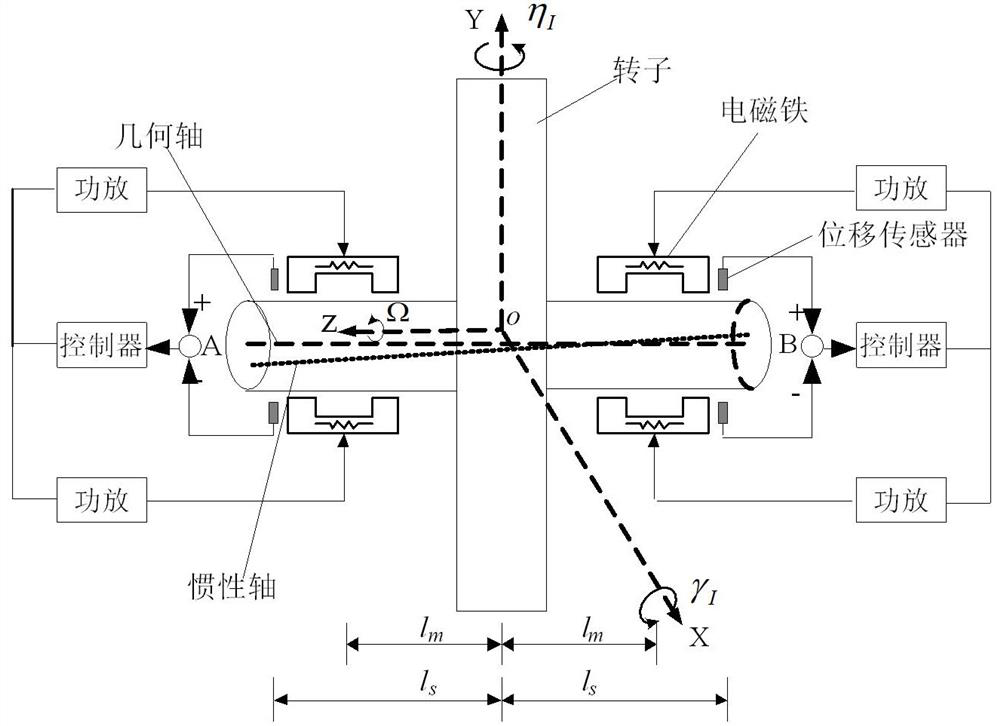

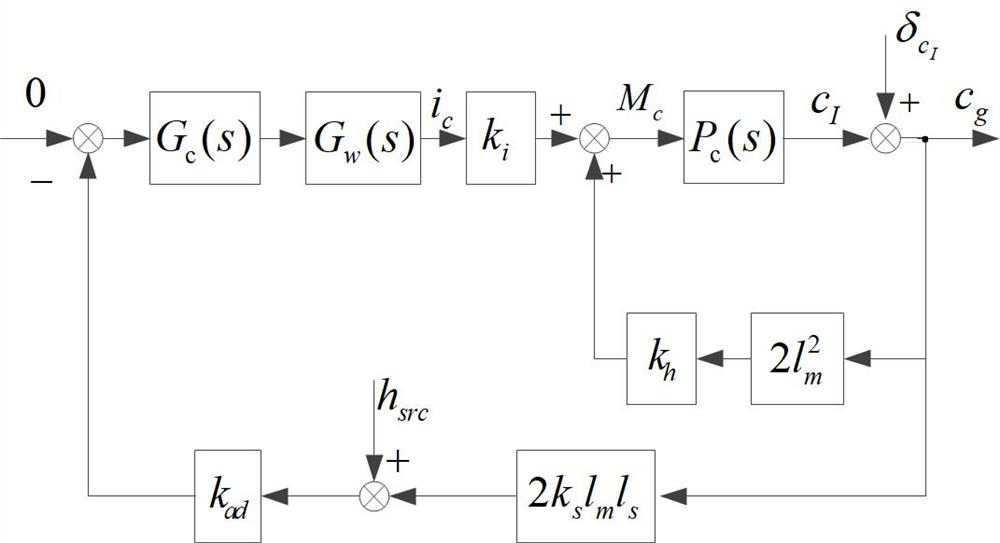

[0042] Such as figure 1 Shown, a kind of magnetic bearing vibration moment suppression method based on complex variable finite-dimensional repeated control of the present invention, its realization process is: at first set up the dynamics model of the magnetic levitation rotor rotation system that includes rotor unbalance and displacement transducer harmonic noise; Then design Magnetic bearing vibration torque suppression algorithm based on parallel complex variable finite-dimensional repetitive control; finally, according to the dual-frequency Bode diagram of the complex variable system function, the parameters of the complex variable finite-dimensional repetitive controller are designed to ensure the stability of the magnetic bearing closed-loop system with strong gyro effect Realize high-precision vibration moment suppression under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com