Patents

Literature

38results about How to "Excellent redox stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

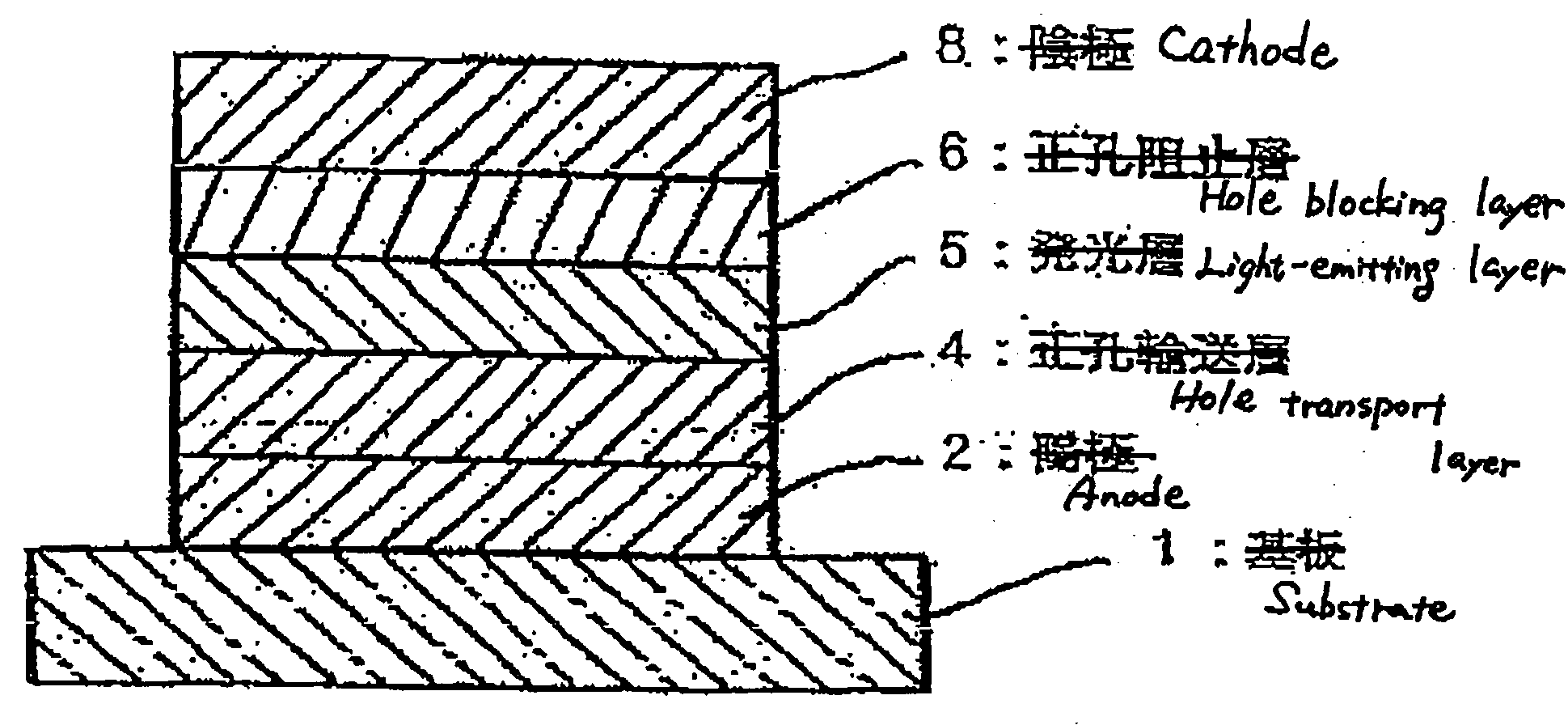

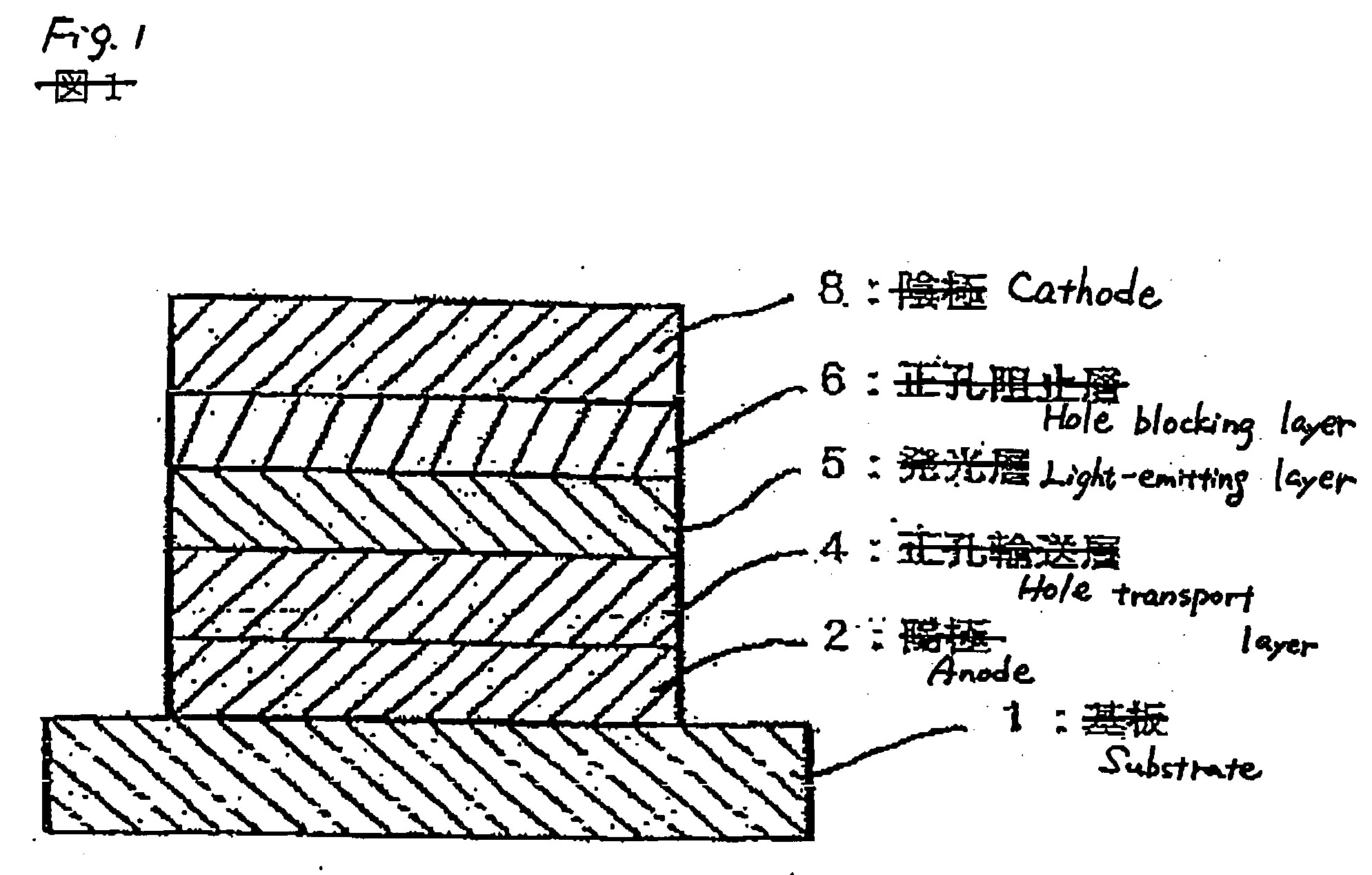

Compound, charge transporting material and organic electroluminescent element

ActiveUS20060186796A1Excellent redox stabilityIncreased durabilityOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescencePolymer chemistry

An object of the invention is to provide a charge transporting material having an excellent heat resistance, excellent filming properties, an excellent charge transporting ability, and excellent light-emitting characteristics and, also, to provide an organic electroluminescent element providing a high luminance and a highly luminous efficiency and having a long life. The invention relates to a charge transporting material comprising a compound having within the molecule two or more pyridine rings substituted at 2-, 4- and 6-positions thereof, which rings do not substantially conjugate each other (provided that the 3- and 5-positions of the pyridine rings may be substituted) and an organic electroluminescent element using the charge transporting material.

Owner:MITSUBISHI CHEM CORP

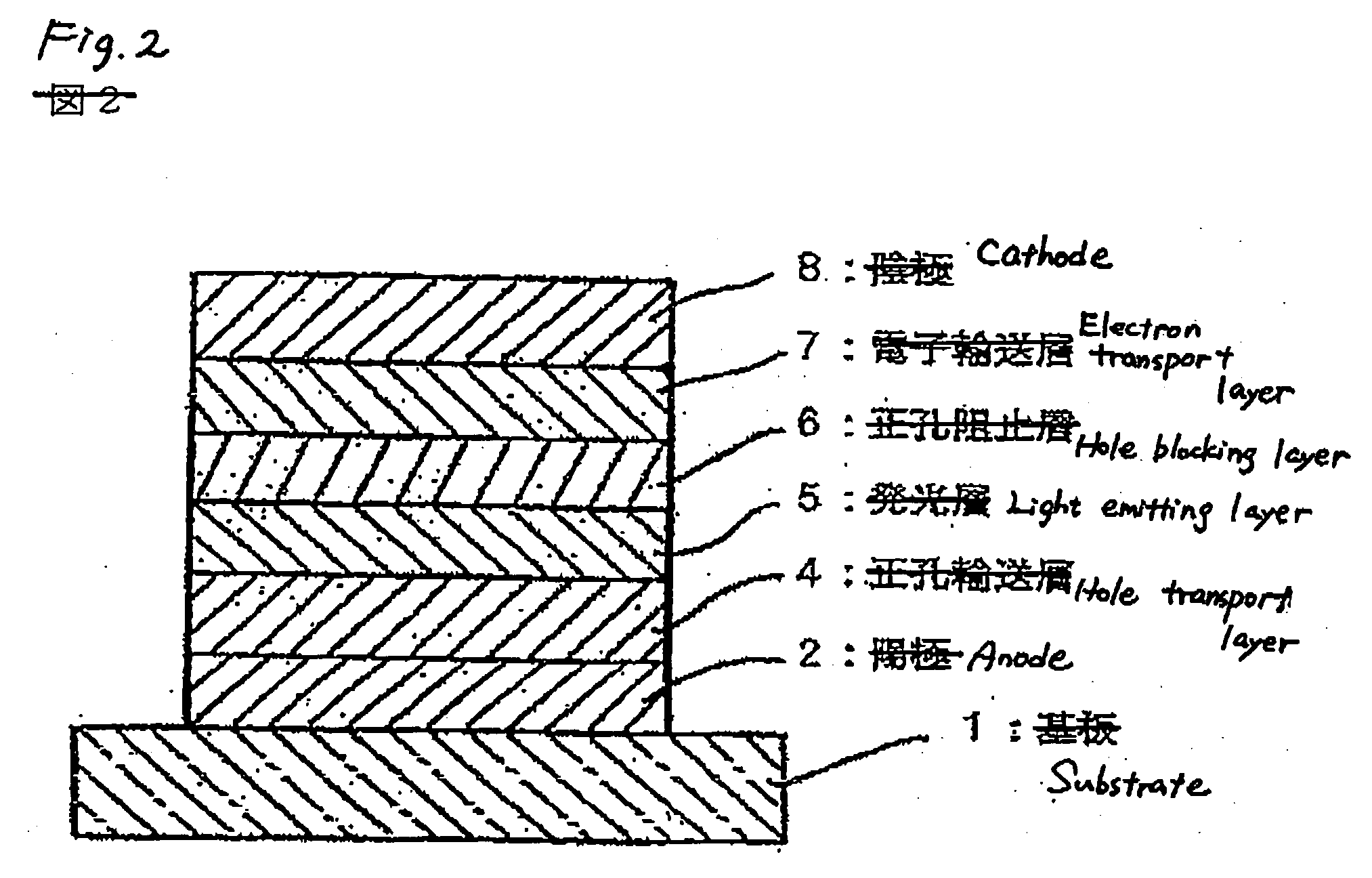

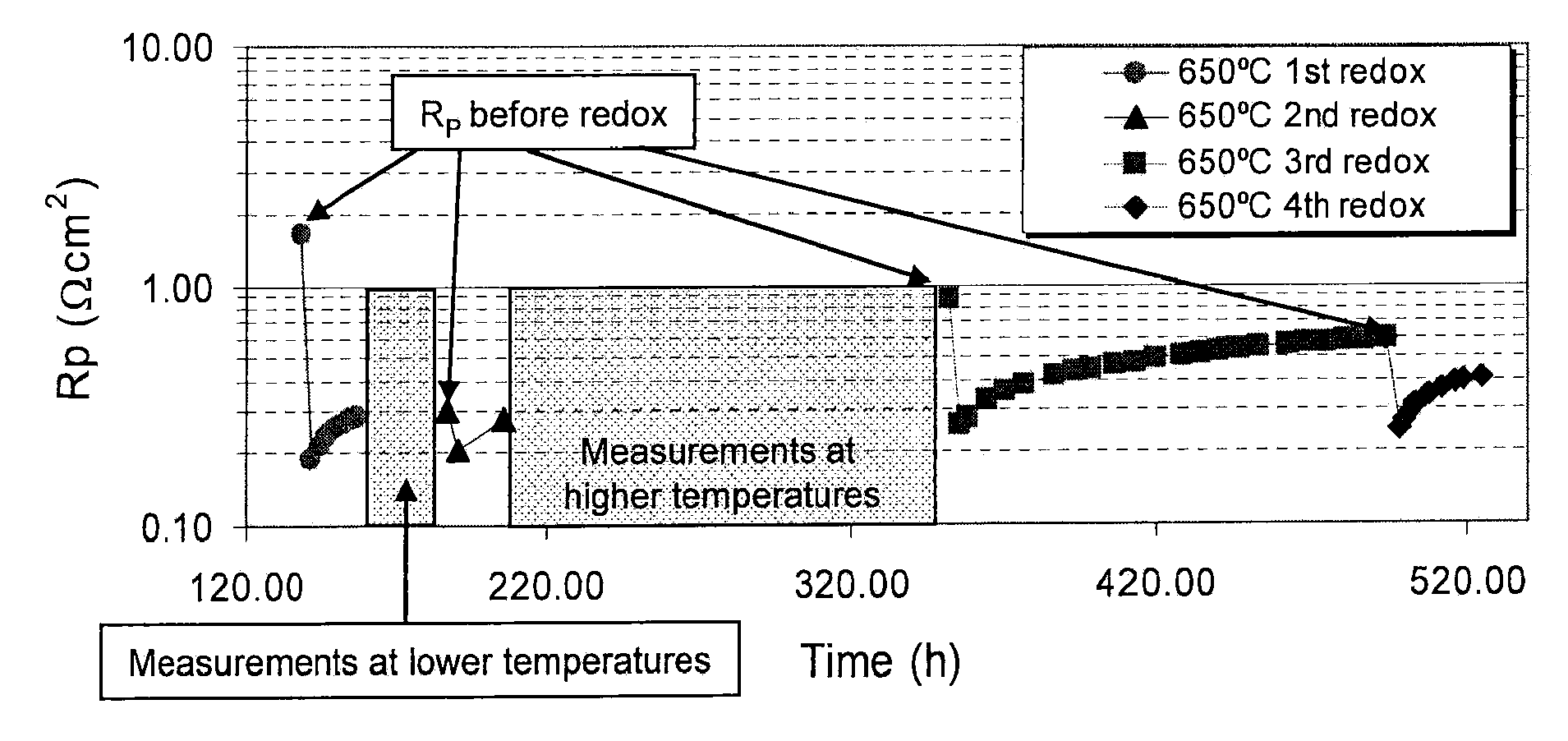

Ceria and strontium titanate based electrodes

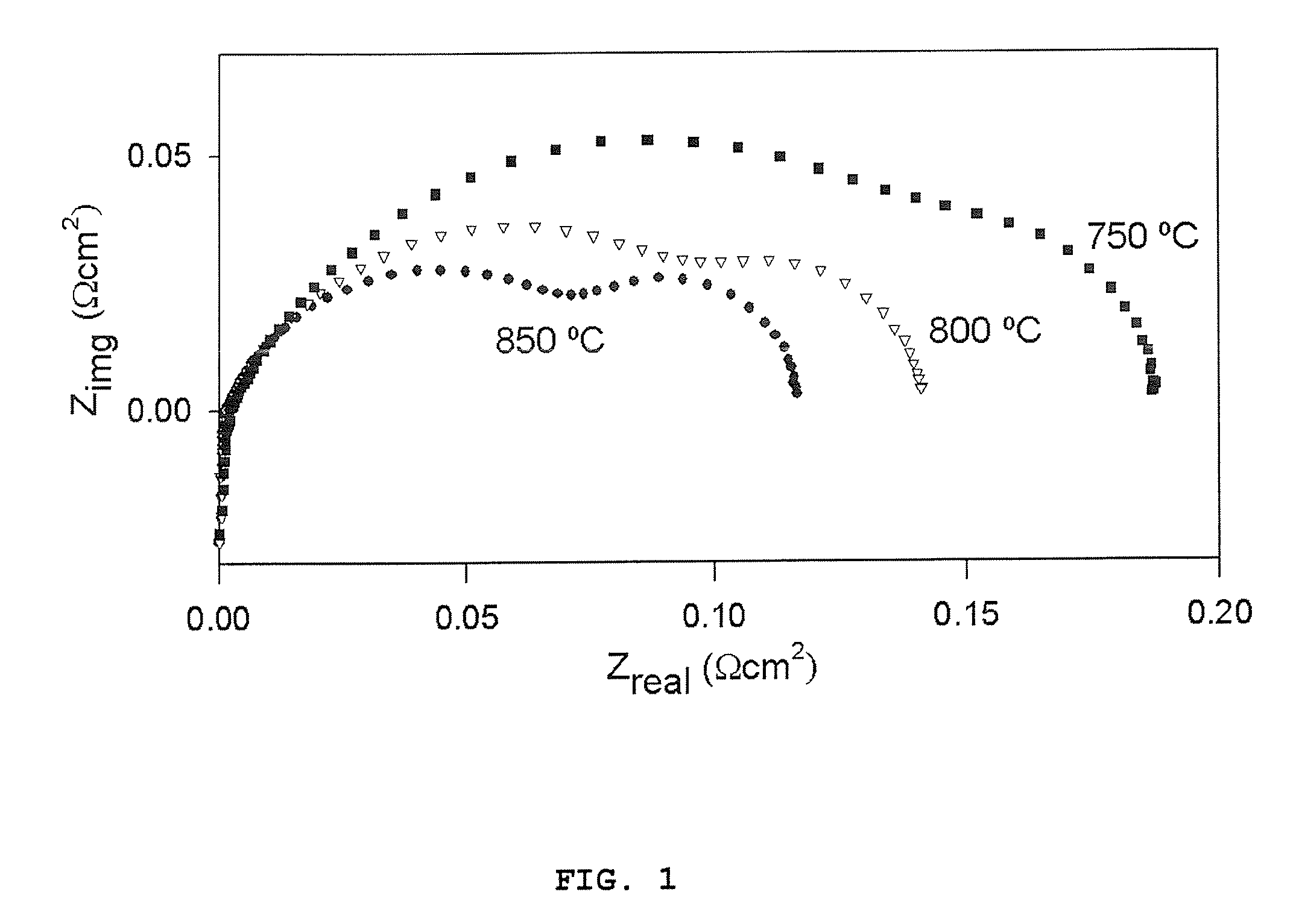

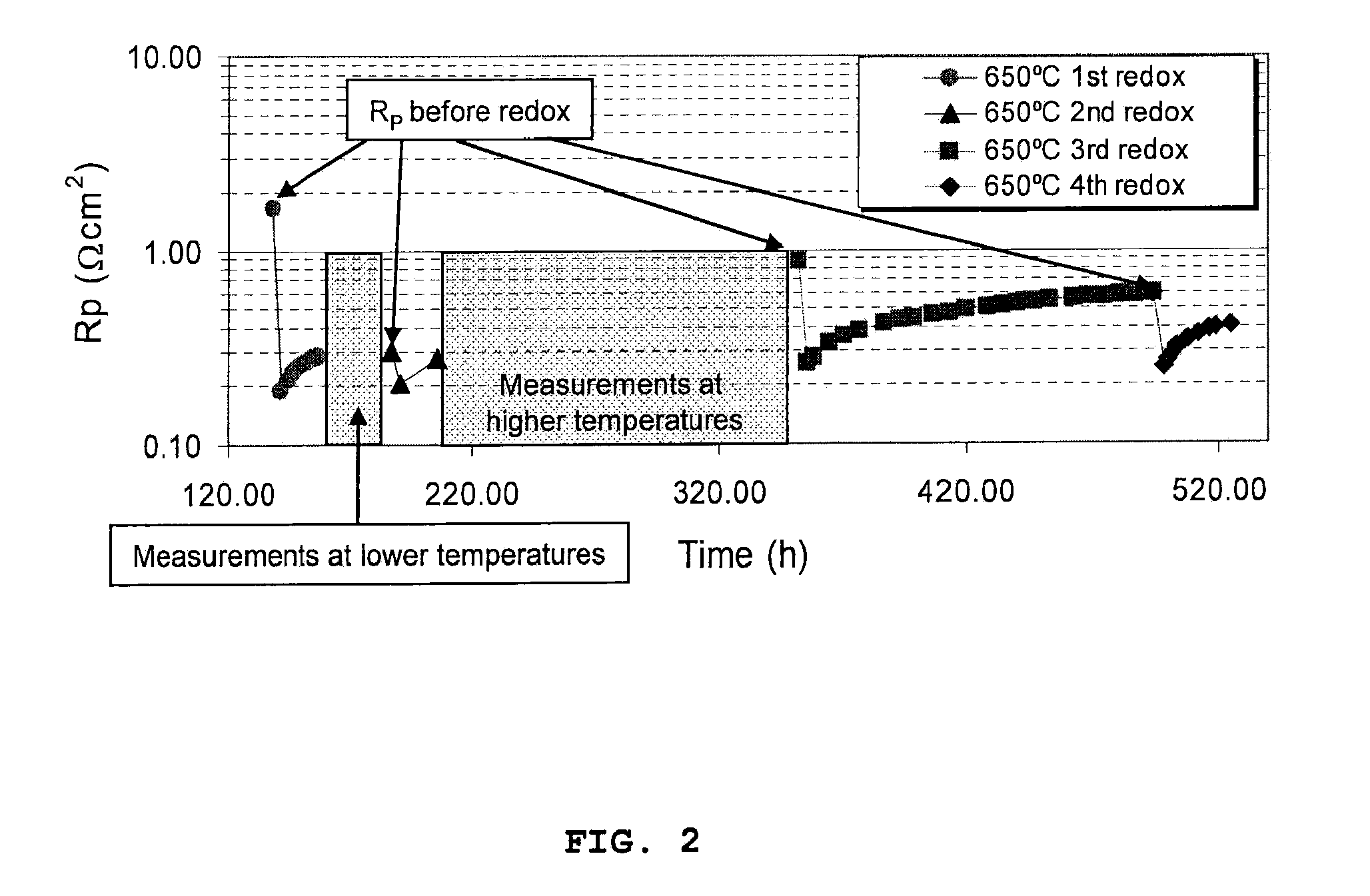

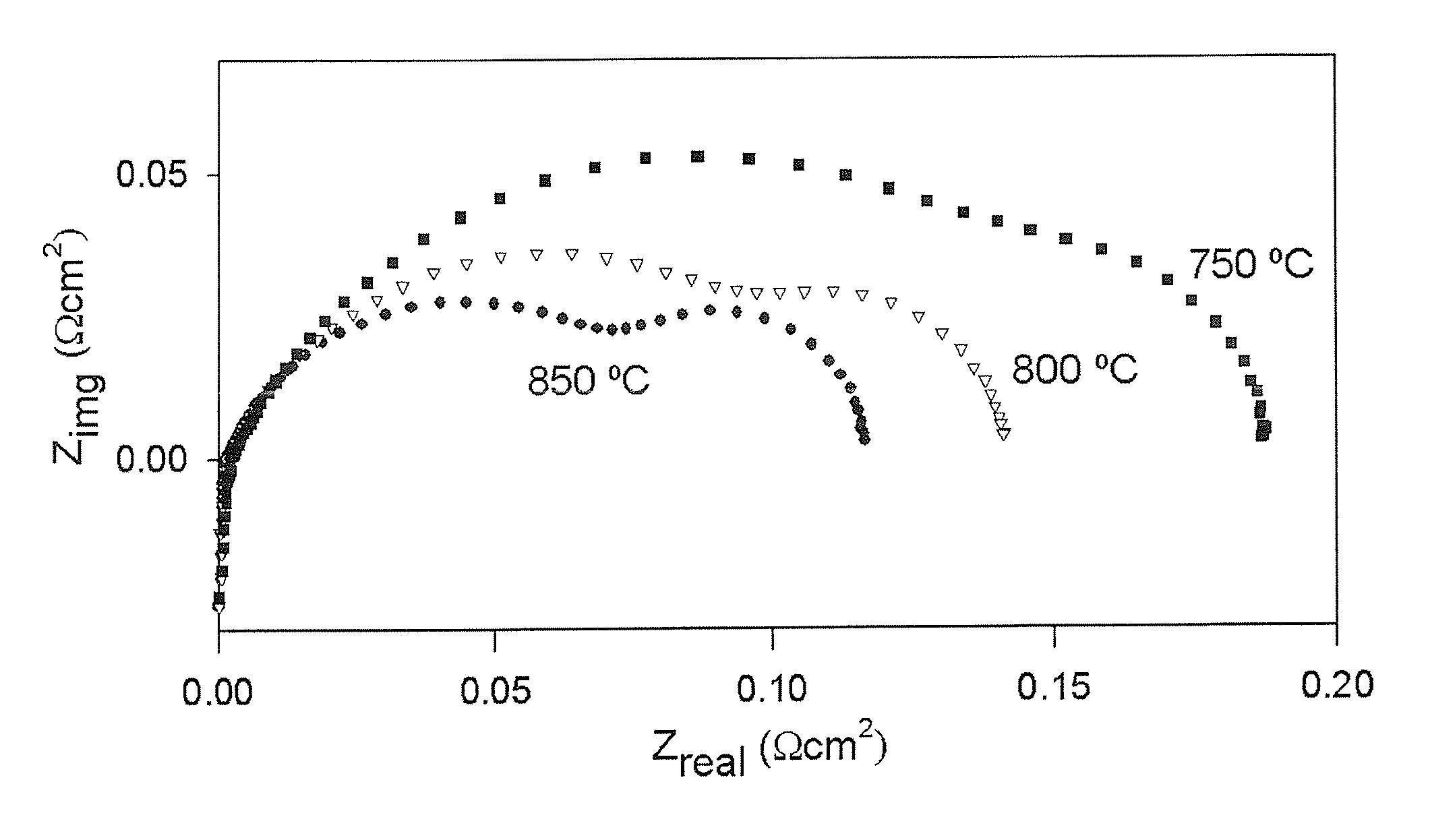

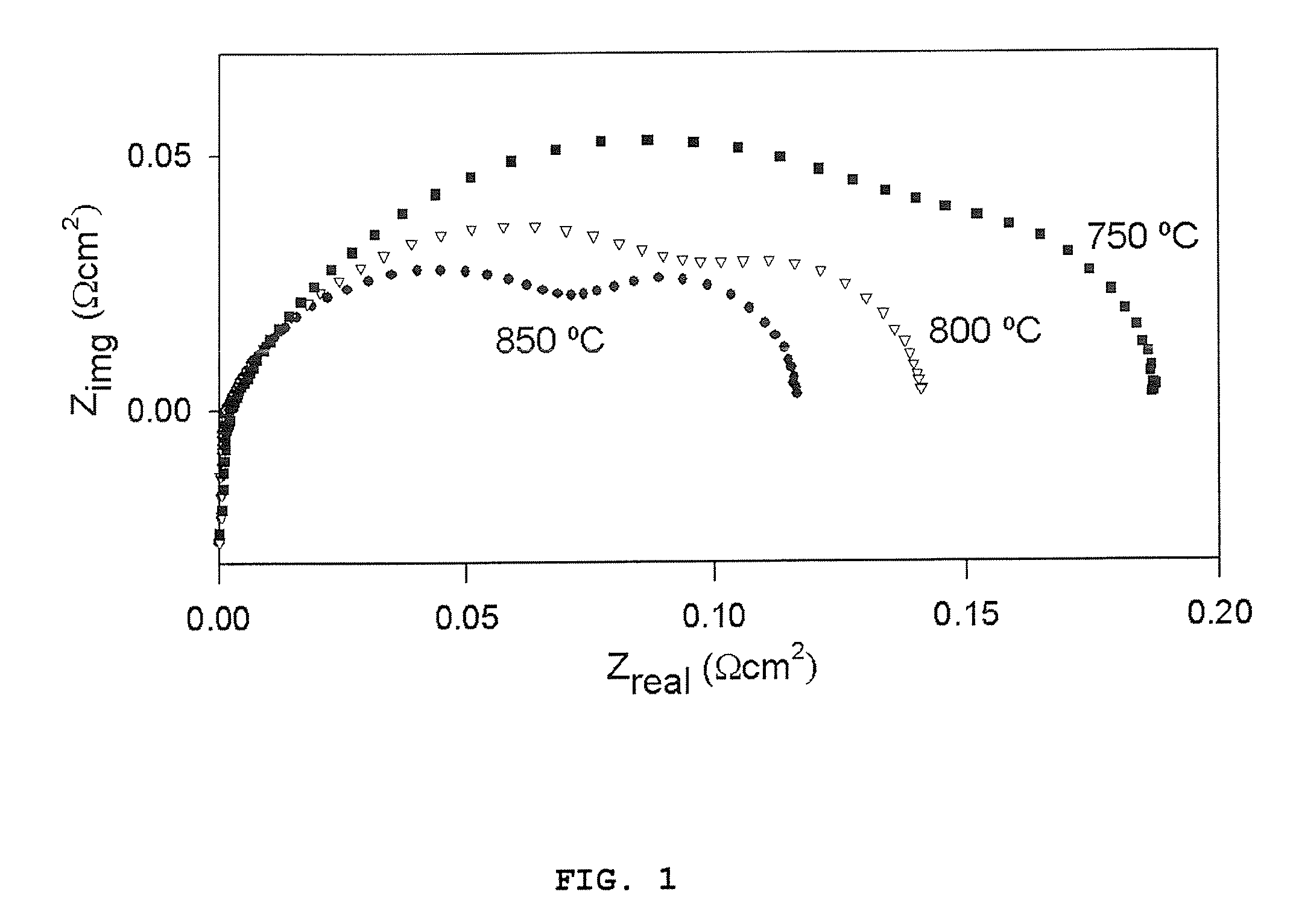

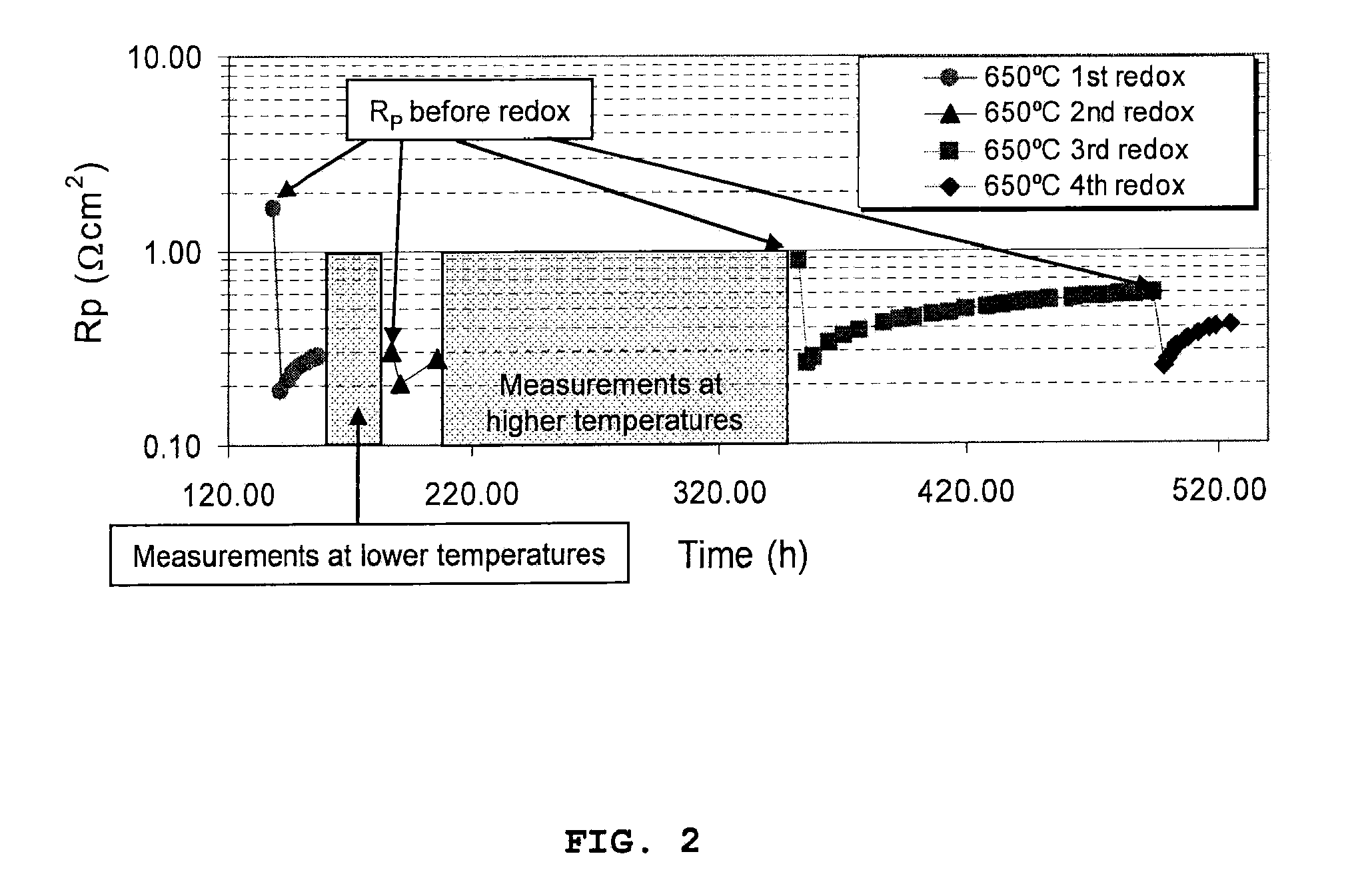

InactiveUS20090061284A1High BET surface areaSpeed up calcination procedureFuel cells groupingCell electrodesStrontium titanateVanadium doping

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

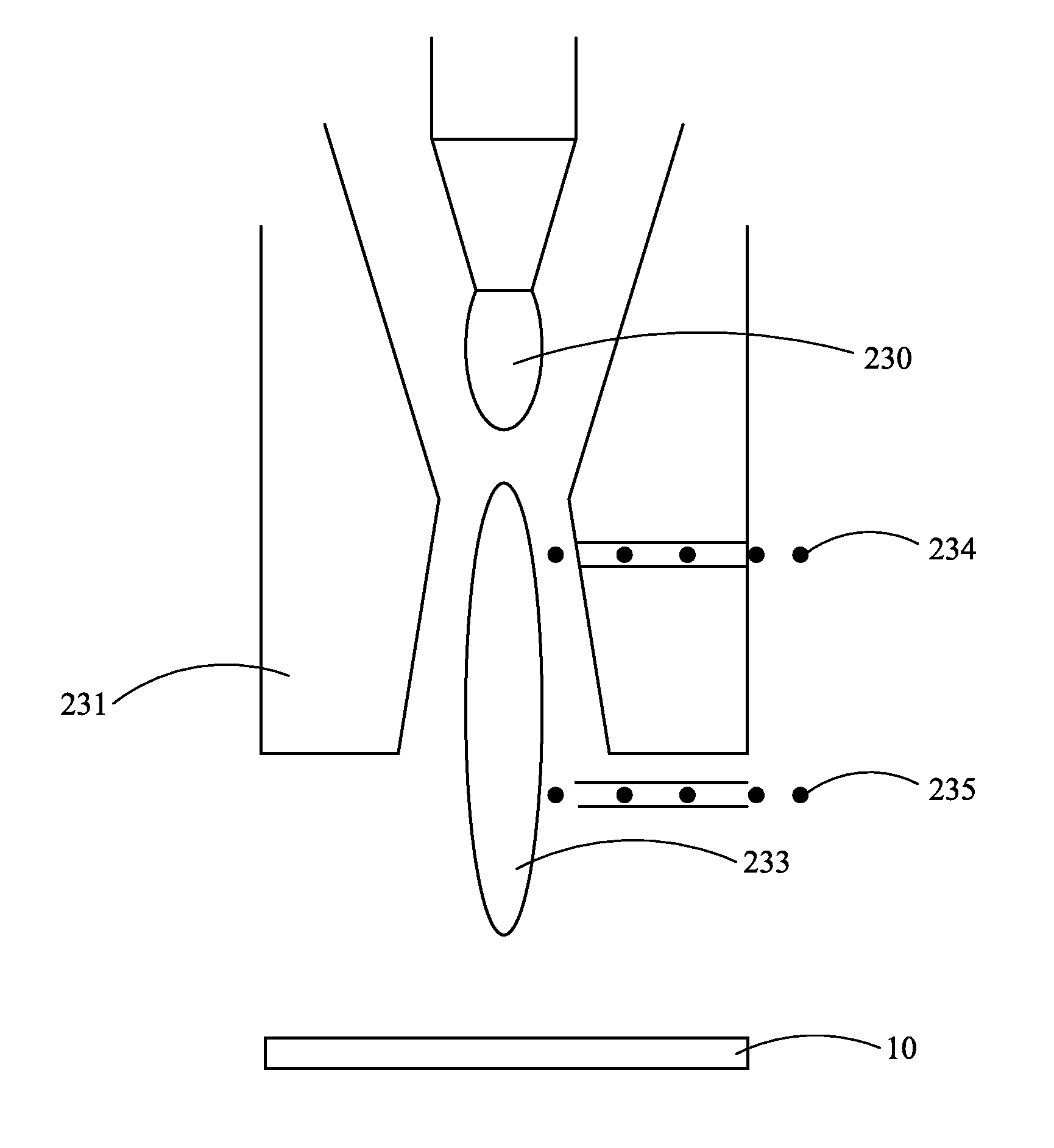

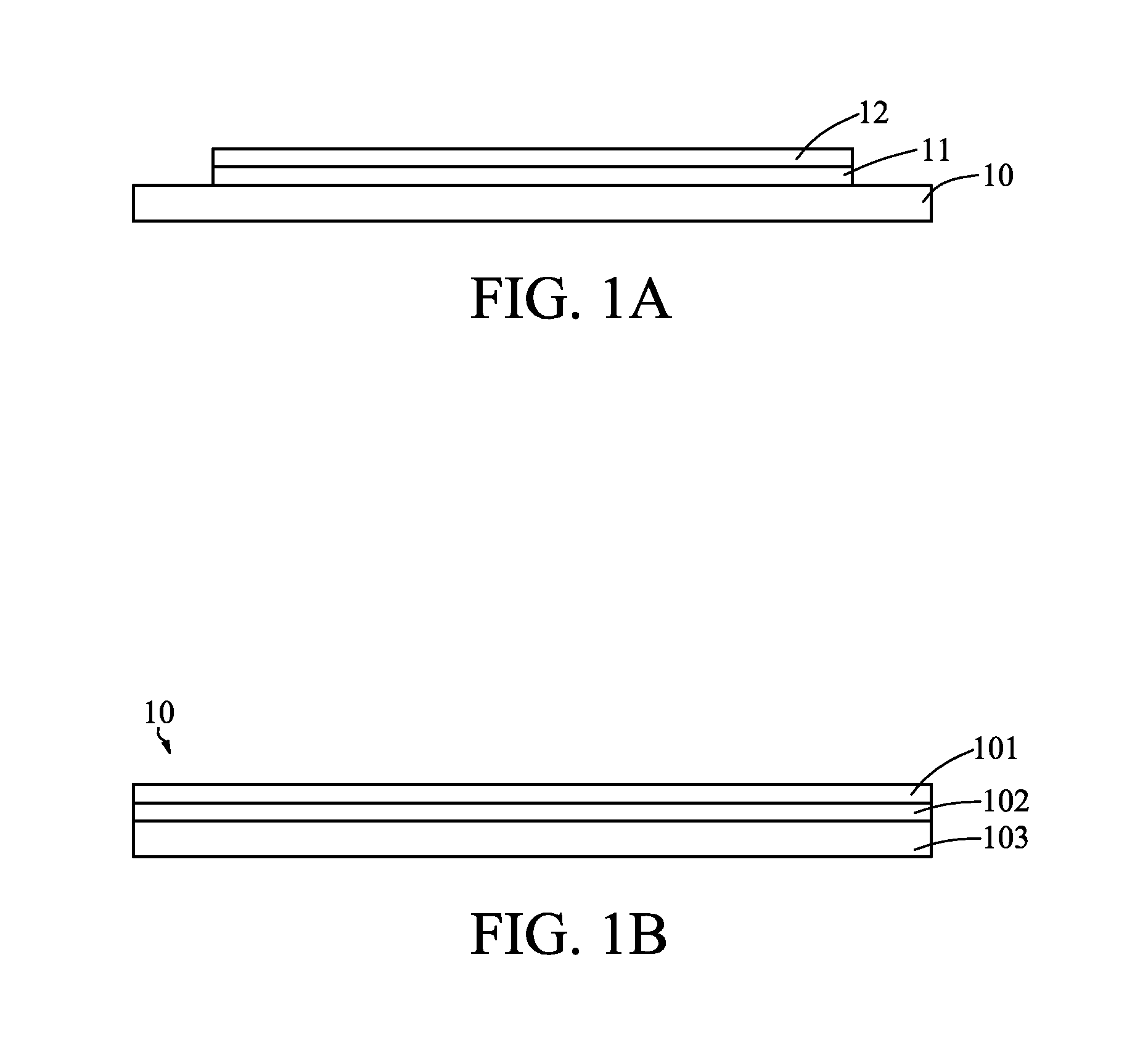

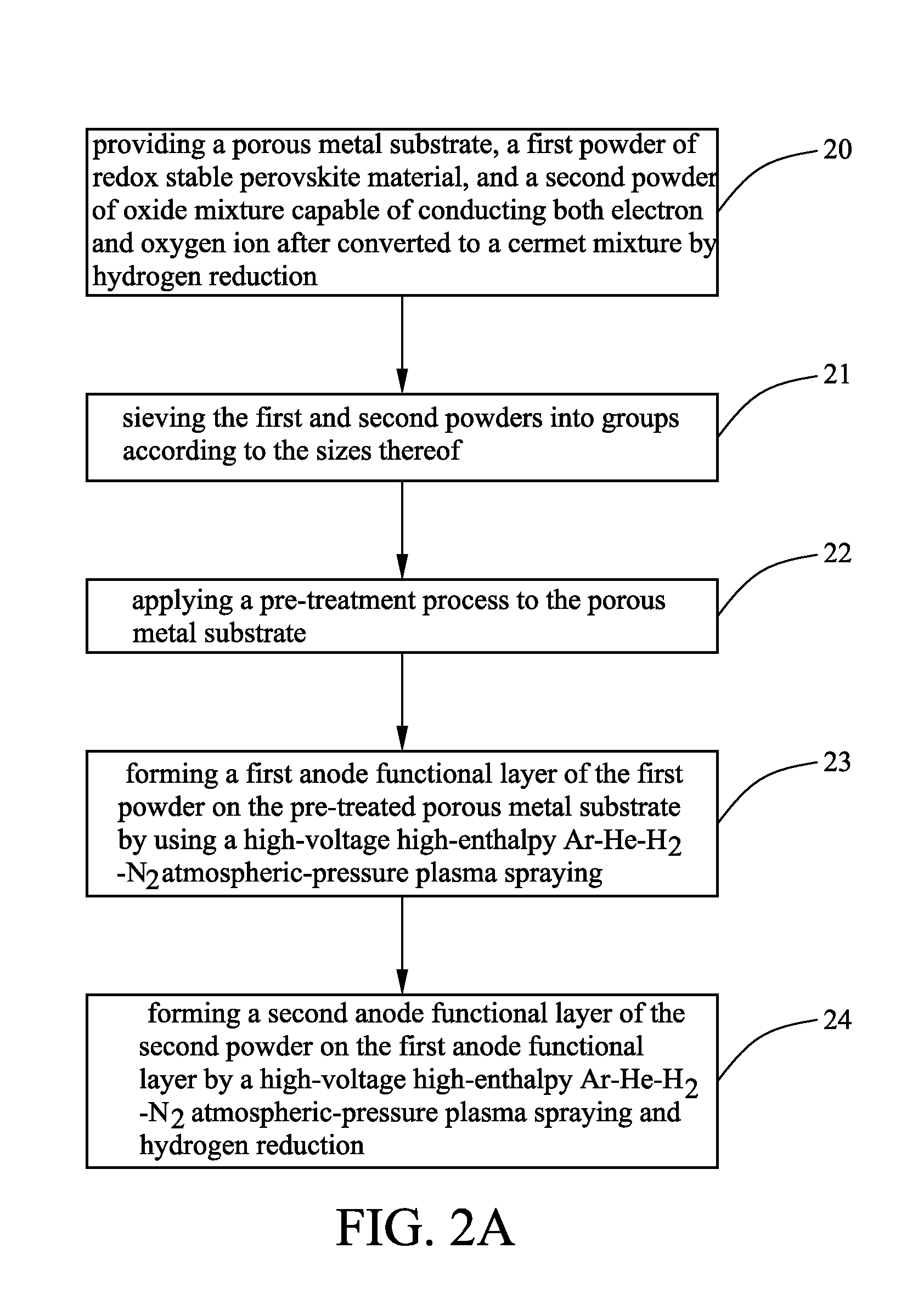

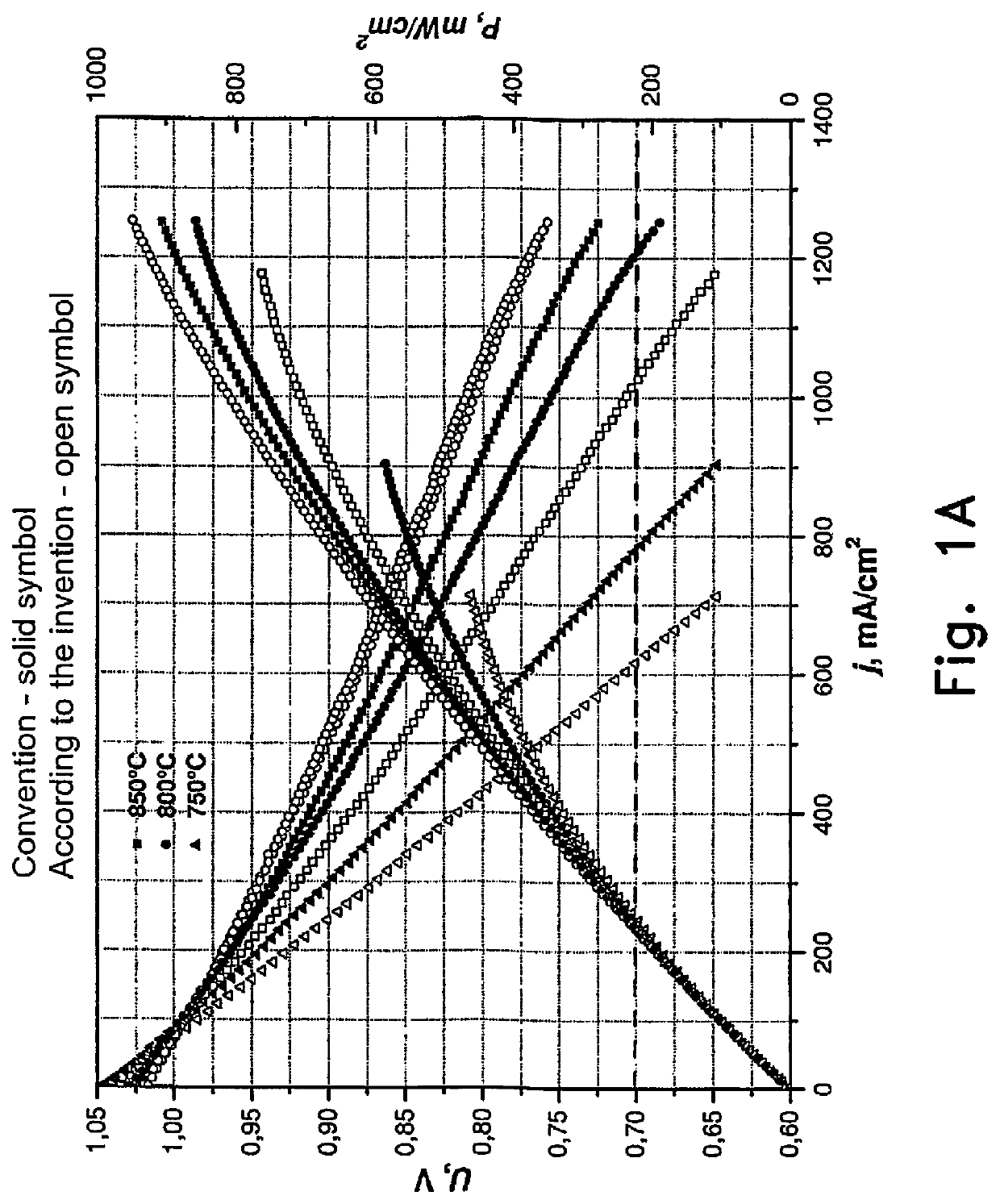

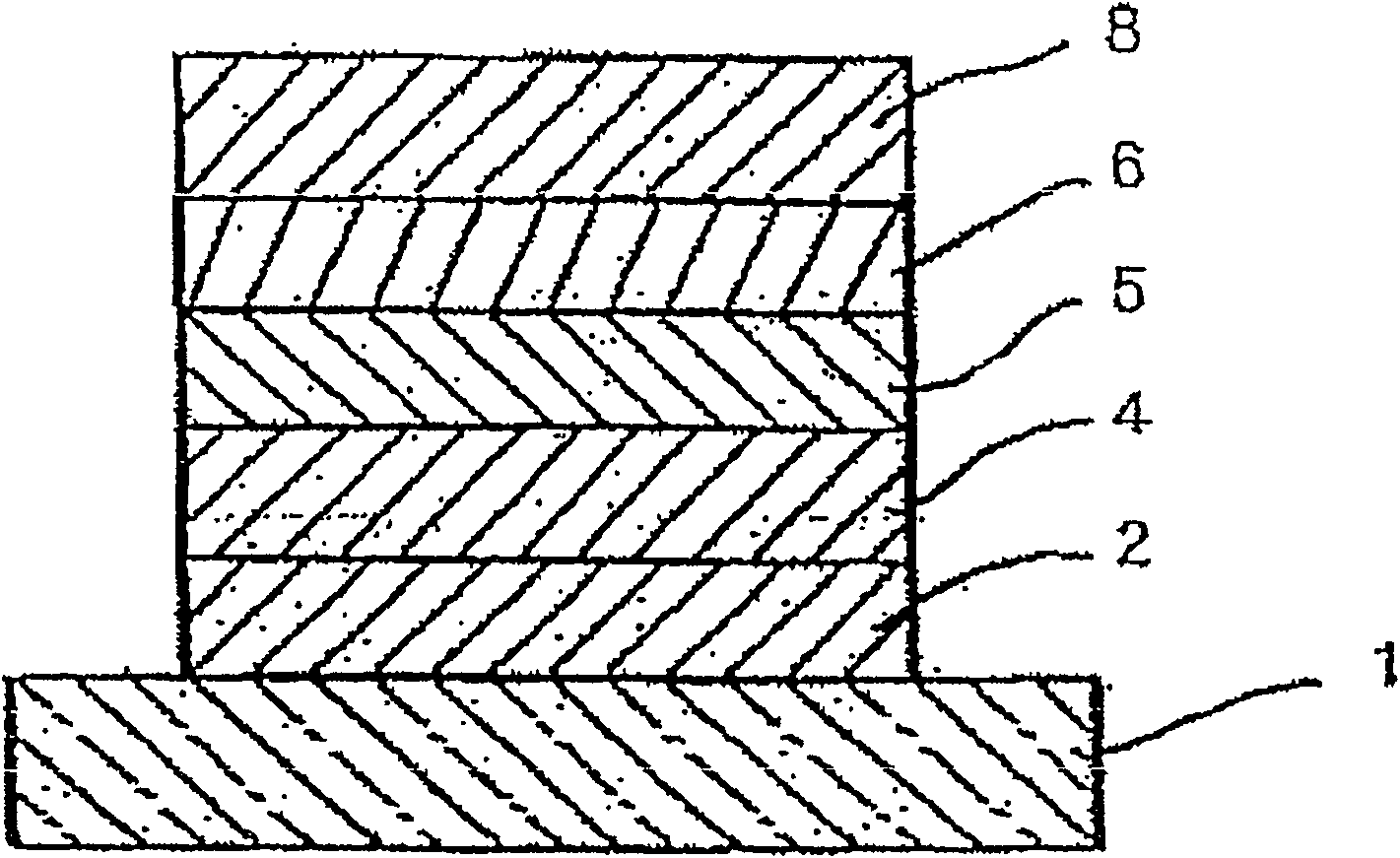

Anode on a pretreated substrate for improving redox-stability of solid oxide fuel cell and the fabrication method therof

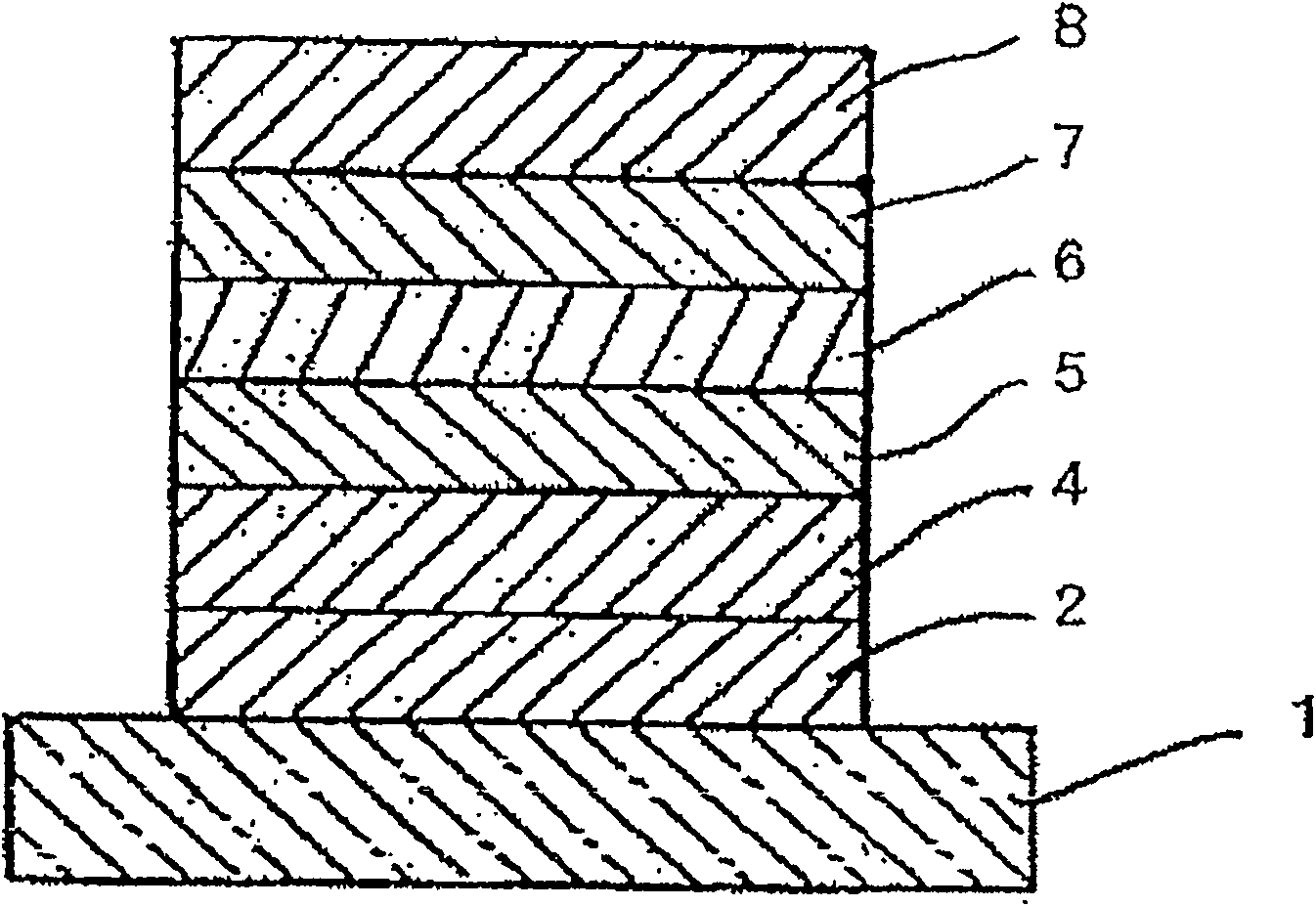

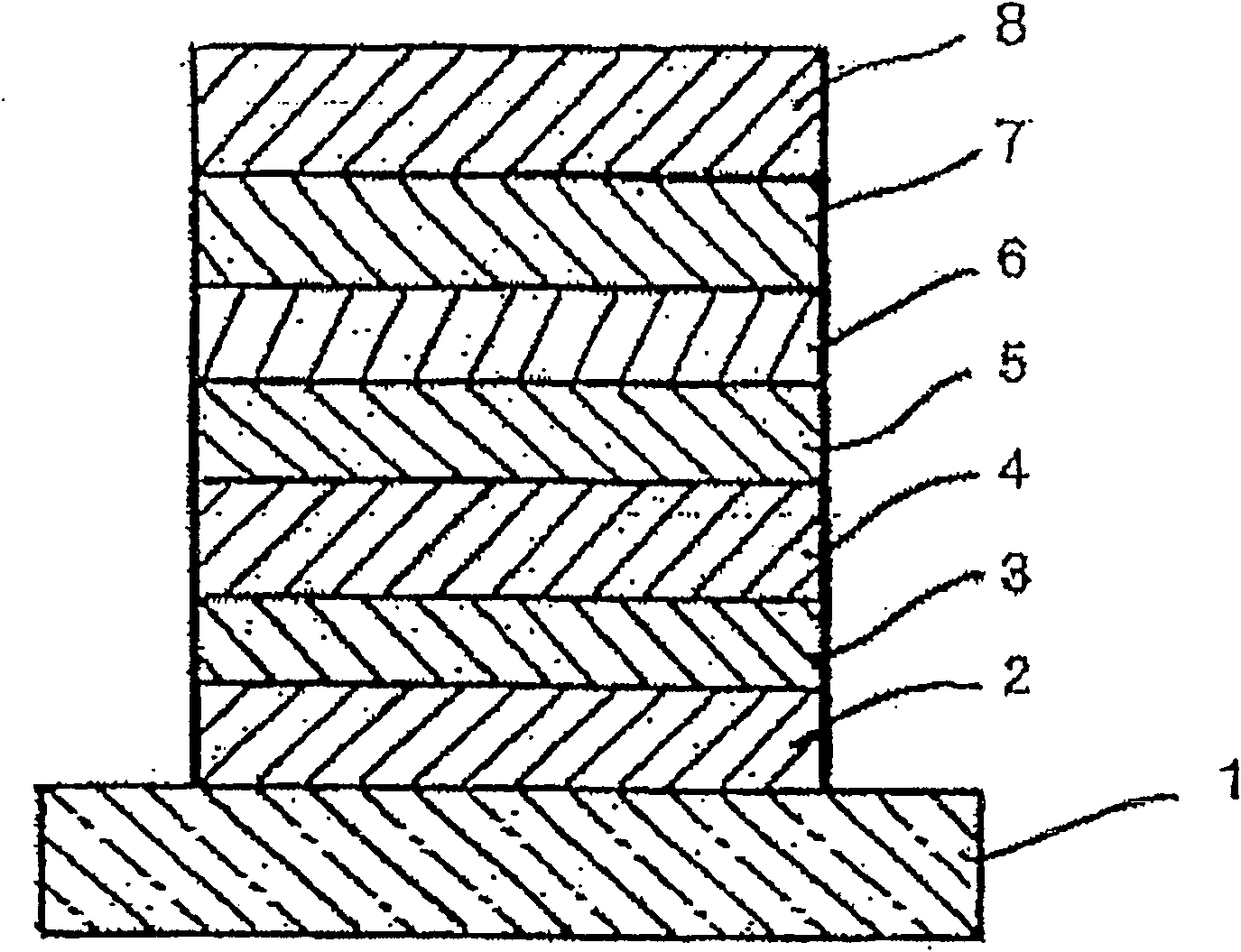

ActiveUS20120021332A1Improve redox abilityDrag minimizationLiquid surface applicatorsMolten spray coatingOptoelectronicsHigh pressure

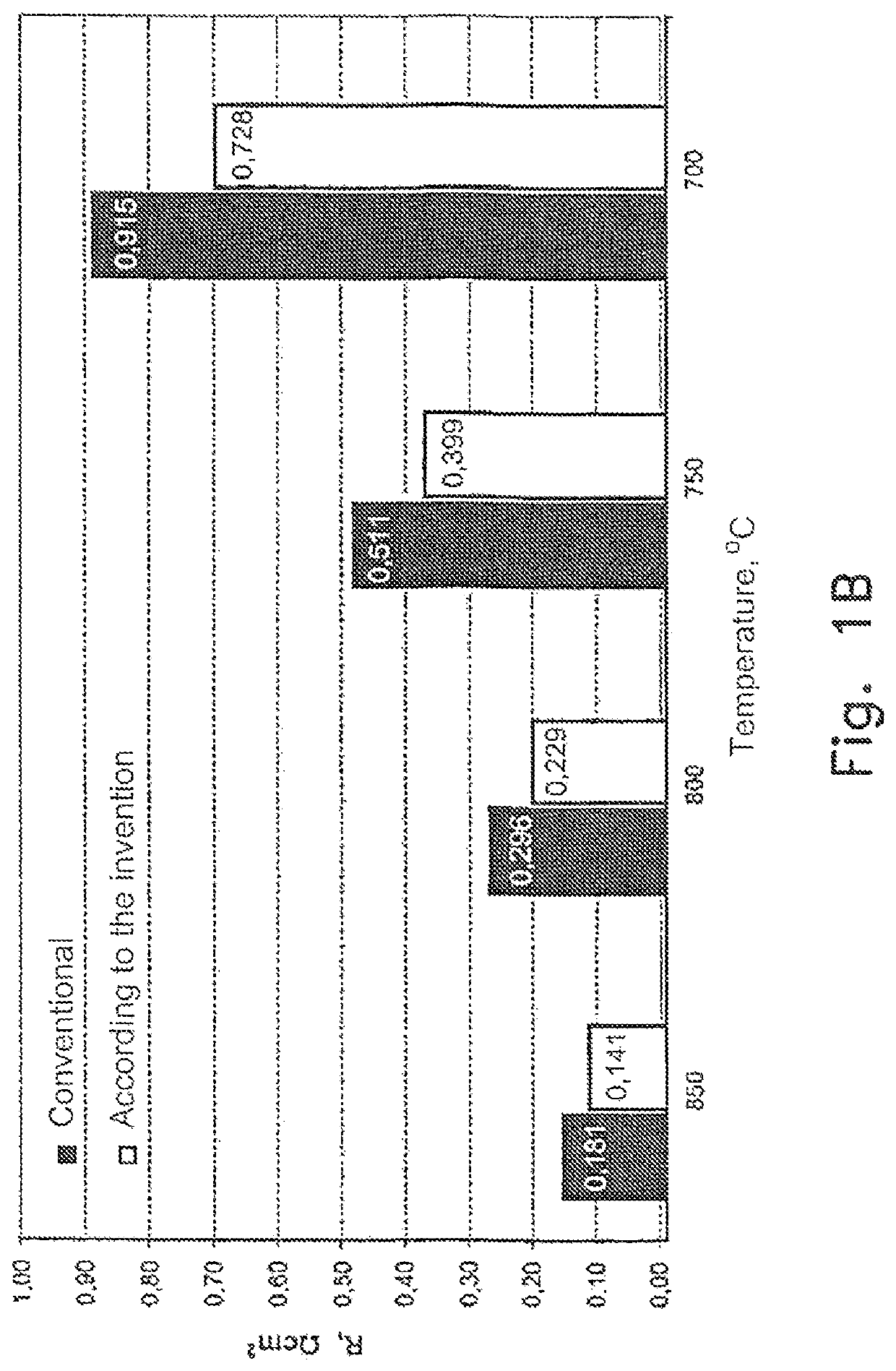

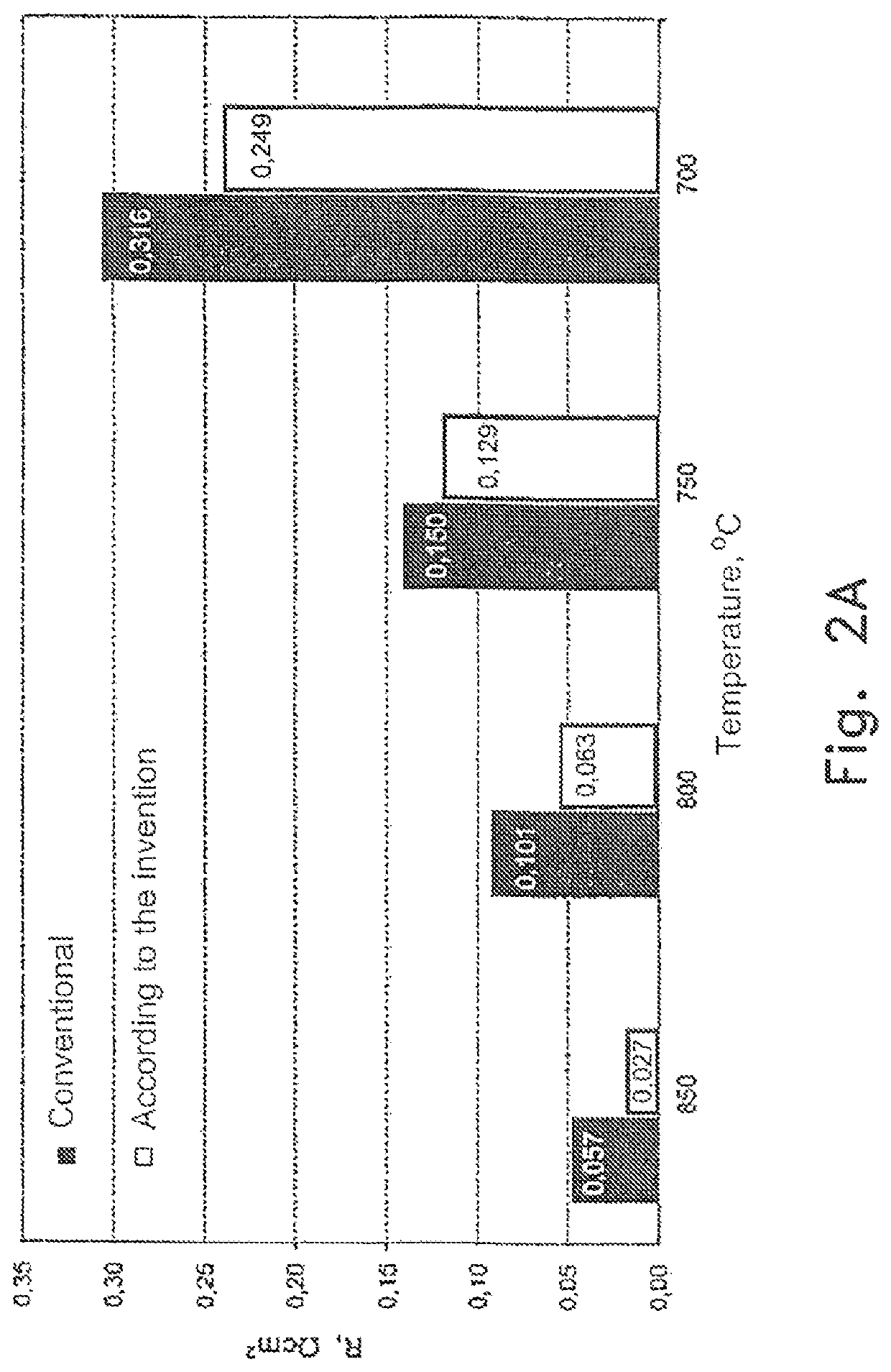

The disclosure provides a double-layer anode structure on a pretreated porous metal substrate and a method for fabricating the same, for improving the redox stability and decreasing the anode polarization resistance of a SOFC. The anode structure comprises: a porous metal substrate of high gas permeability; a first porous anode functional layer, formed on the porous metal substrate by a high-voltage high-enthalpy Ar—He—H2—N2 atmospheric-pressure plasma spraying process; and a second porous anode functional layer, formed on the first porous anode functional layer by a high-voltage high-enthalpy Ar—He—H2—N2 atmospheric-pressure plasma spraying and hydrogen reduction. The first porous anode functional layer is composed a redox stable perovskite, the second porous anode functional layer is composed of a nanostructured cermet. The first porous anode functional layer is also used to prevent the second porous anode functional layer from being diffused by the composition elements of the porous metal substrate.

Owner:INST NUCLEAR ENERGY RES ROCAEC

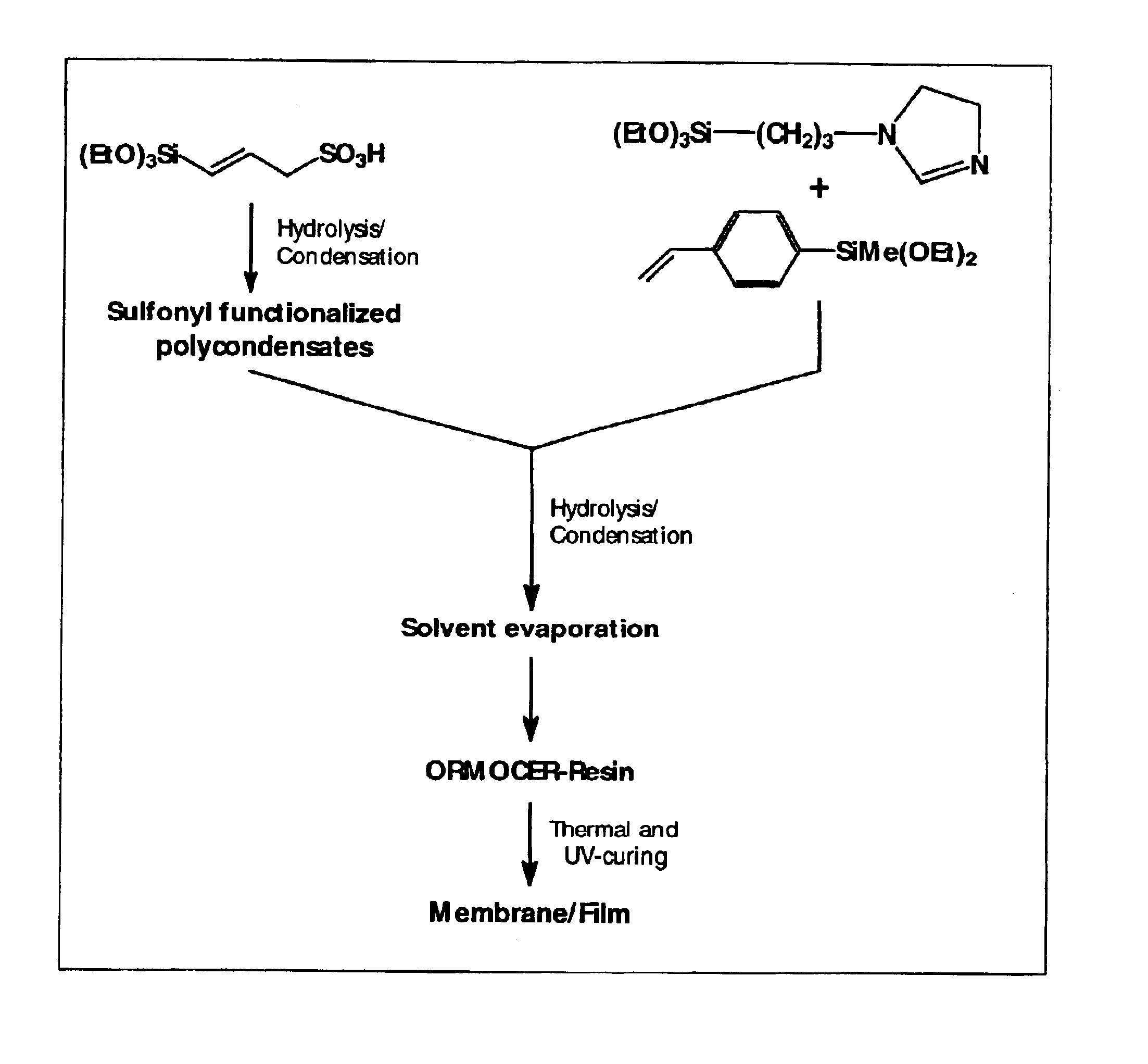

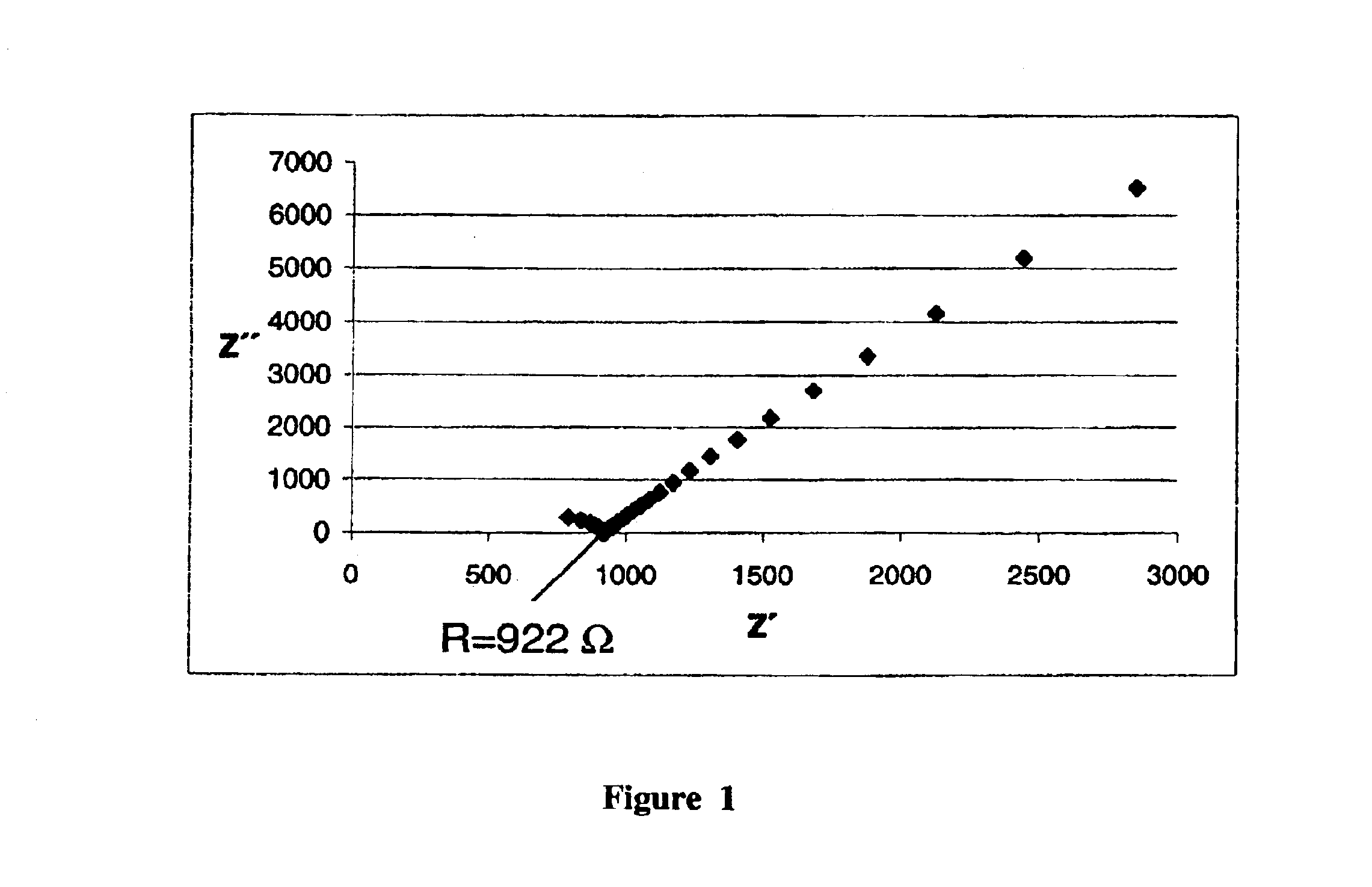

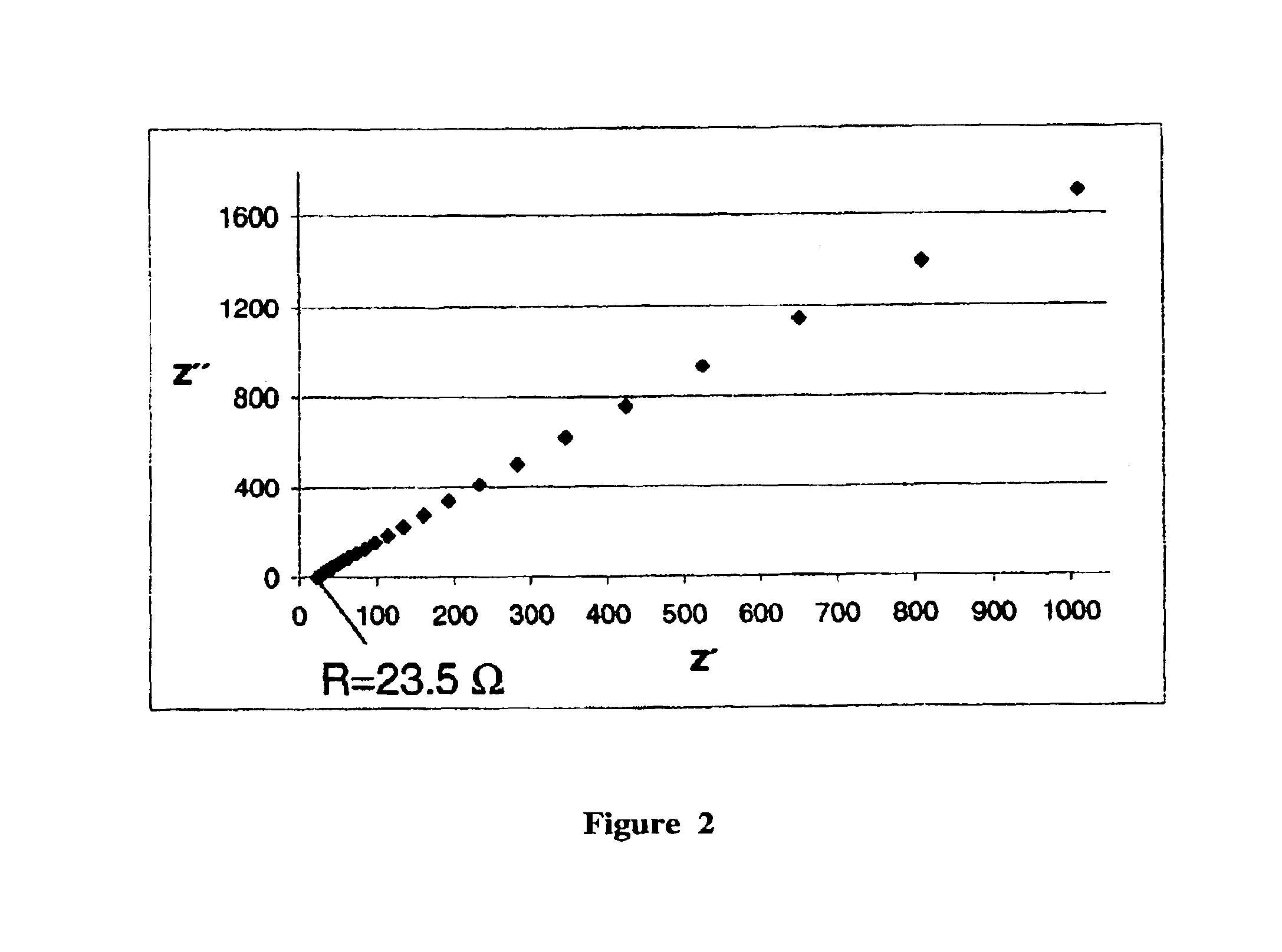

Proton-conductive membranes and layers and methods for their production

InactiveUS6949616B2Improved PEMFC outputIncrease valueSemi-permeable membranesFinal product manufactureCross-linkPartial hydrolysis

This invention relates to a silane-resin composition that can be obtained by at least partial hydrolytic condensation of at least the following components: (1) one or more sulfonic acid group-containing silane(s) with at least one group that can be cleaved under hydrolytic conditions, (2) one or more styryl-functionalized silane(s) and (3) one or more silane(s) that carry a nitrogen-containing heterocyclic compound, an amine group or a sulfonamide group with at least one group that can be cleaved under hydrolytic conditions, and mixing of the components before, during or after the hydrolytic condensation, as well as a process for the production of this composition. With the silane resin that is obtained, proton-conductive, organically cross-linked heteropolysiloxanes can be produced that are suitable for PEMFC in a layer or membrane form as proton-conductive systems. Their proton conductivity can be further increased by the addition of suitable liquids.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Zero-PGM TWC with High Redox Reversibility

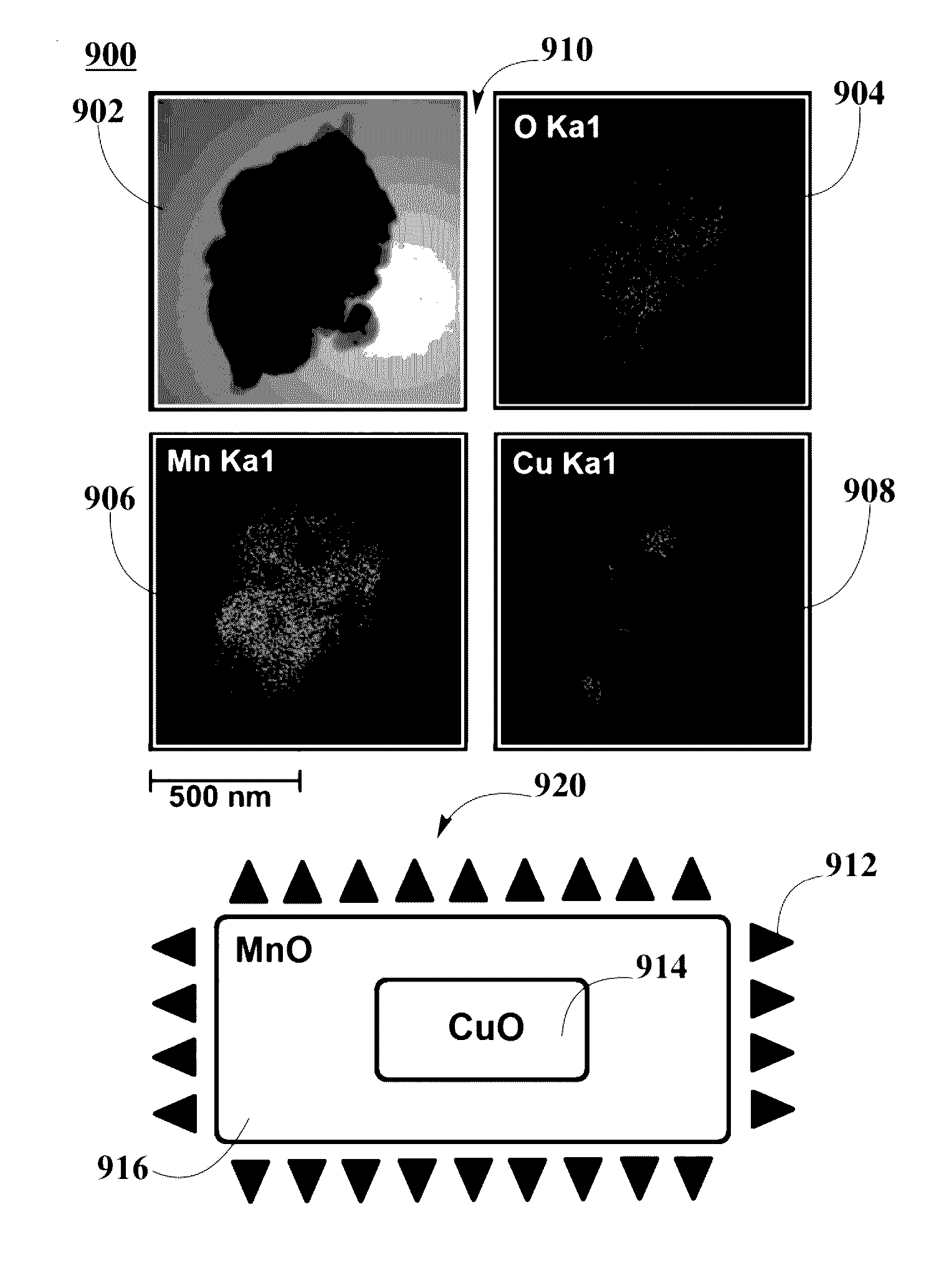

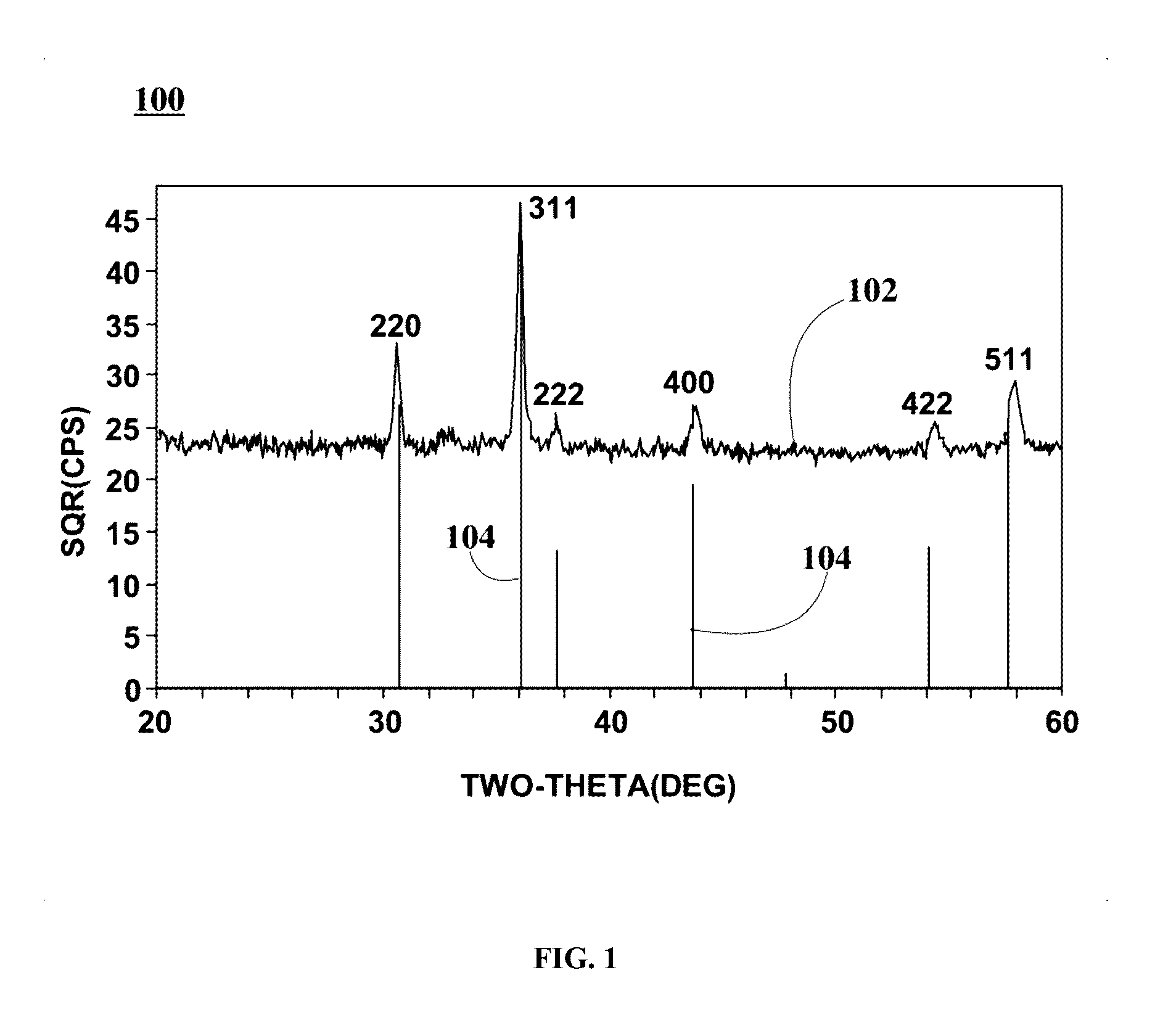

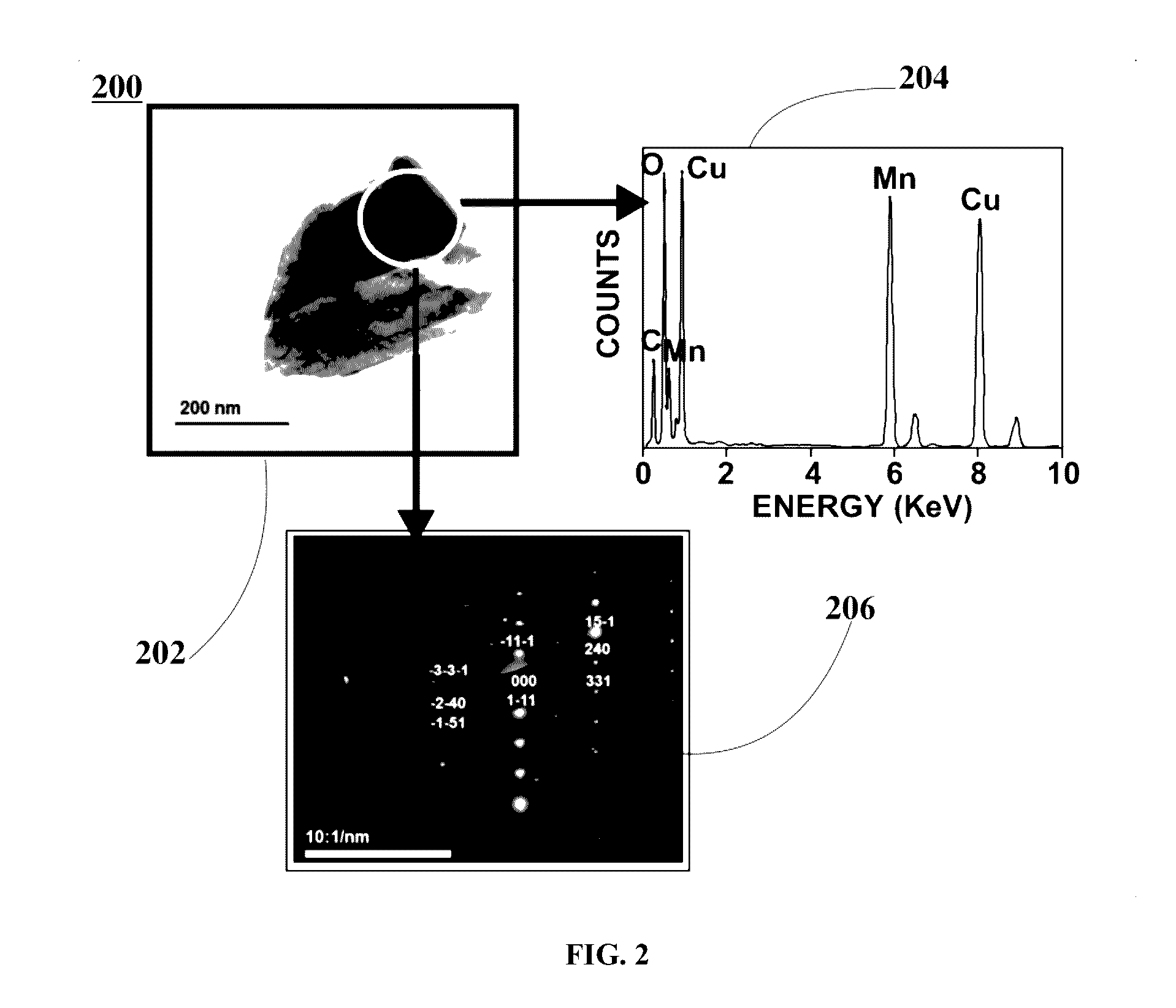

InactiveUS20160361711A1Excellent redox stabilitySignificant reversibilityNitrous oxide captureInternal combustion piston enginesTransmission electron microscopyOxide

The present disclosure describes zero-platinum group metals (ZPGM) material compositions including binary Cu—Mn spinel oxide powders having stable reduction / oxidation (redox) reversibility useful for TWC and oxygen storage material applications. The behavior of Cu—Mn spinel oxide powder is analyzed under oxidation-reduction environments to determine redox reversibility, catalytic activity, and spinel structure stability. Characterization of spinel powder is performed employing X-ray diffraction analysis, hydrogen temperature-programmed reduction technique, transmission electron microscopy analysis, and X-ray photoelectron spectroscopy analysis. Test results confirm the phase and structural stability of the Cu—Mn spinel oxide during redox reaction, thereby indicating that the Cu—Mn spinel oxide can be employed in a plurality of TWC applications.

Owner:CLEAN DIESEL TECHNOLOGIES

Catalysts for the ammoxidation of alkanes

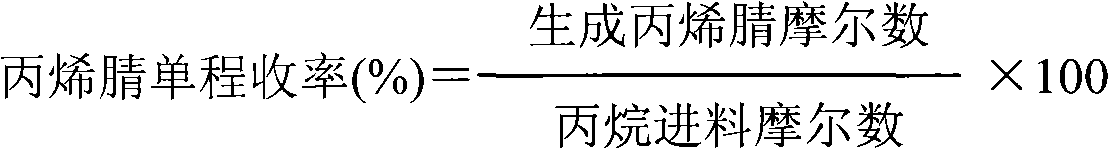

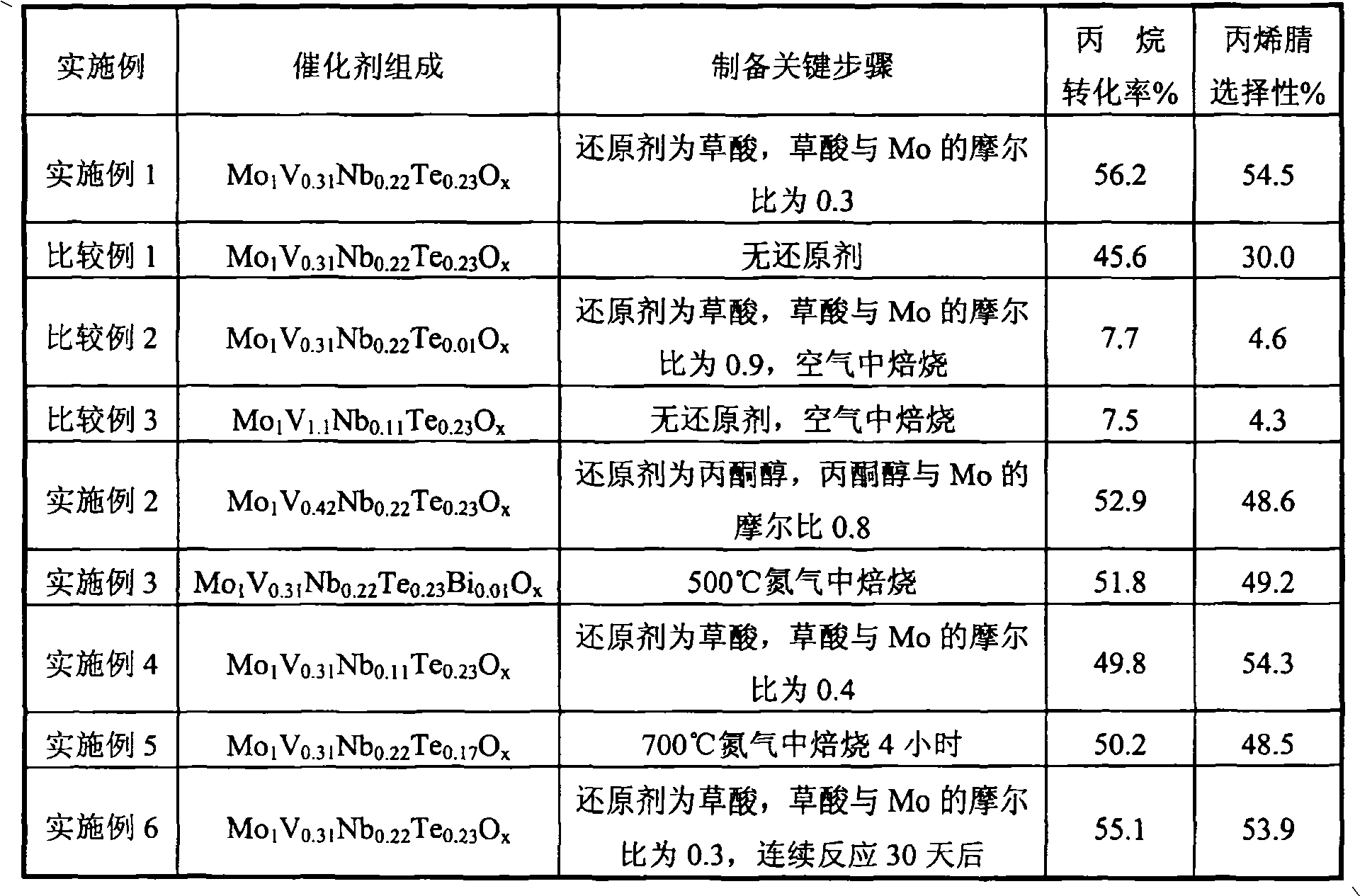

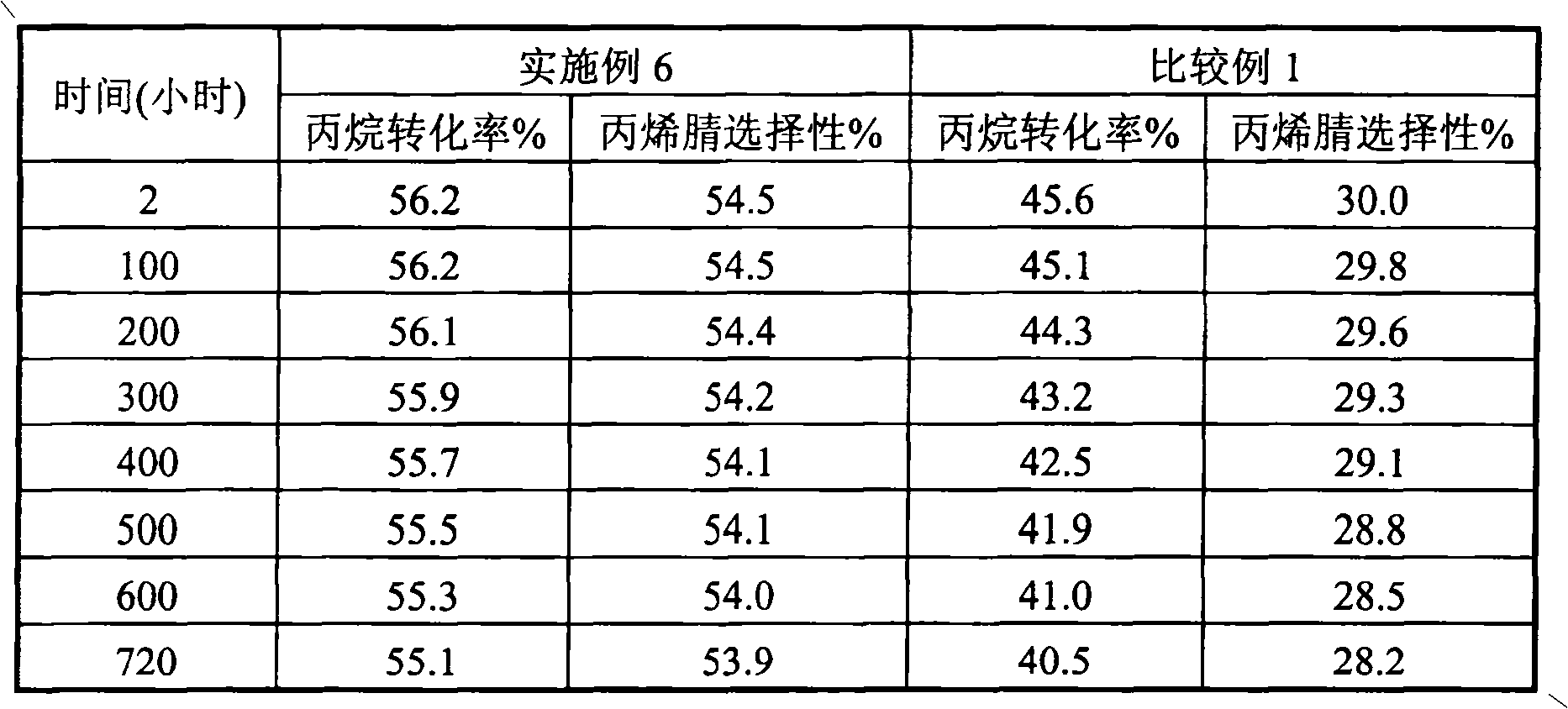

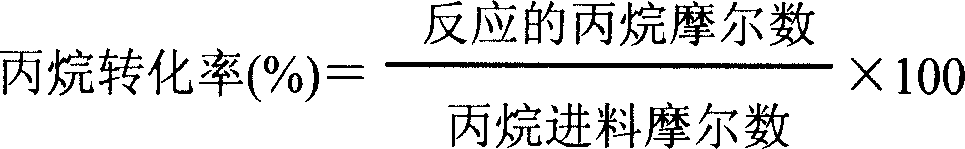

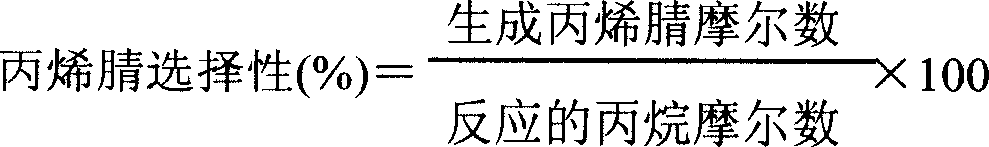

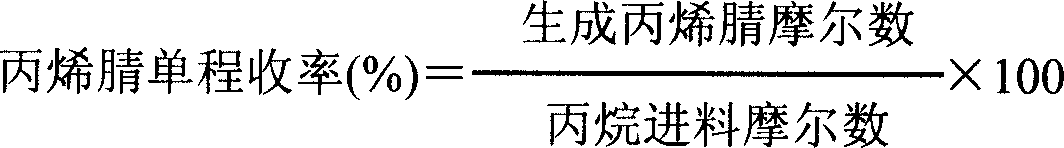

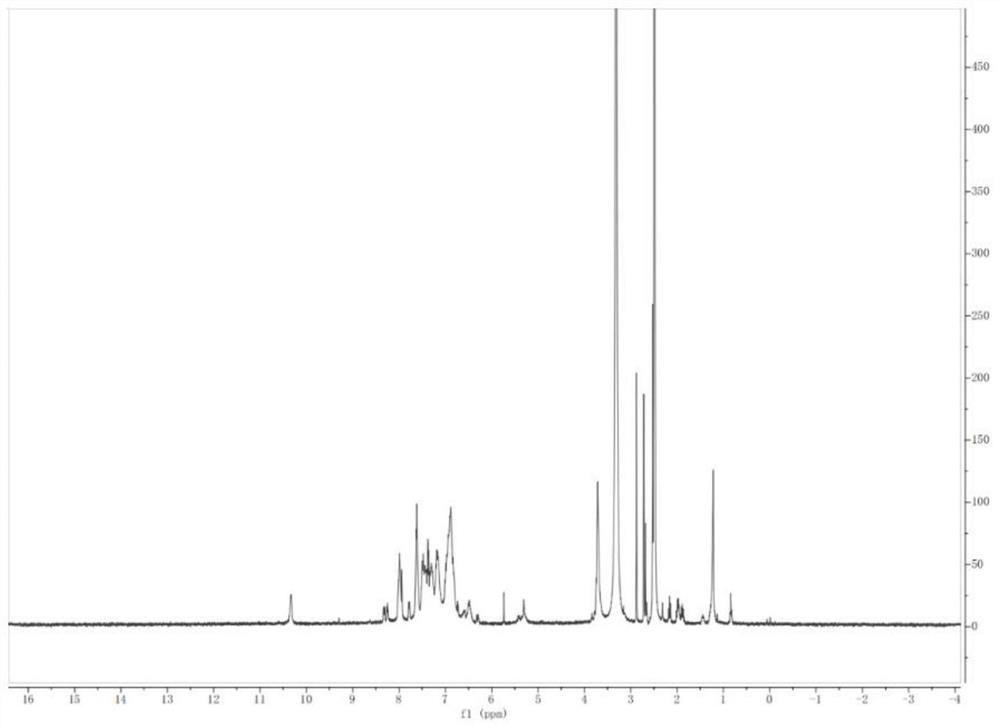

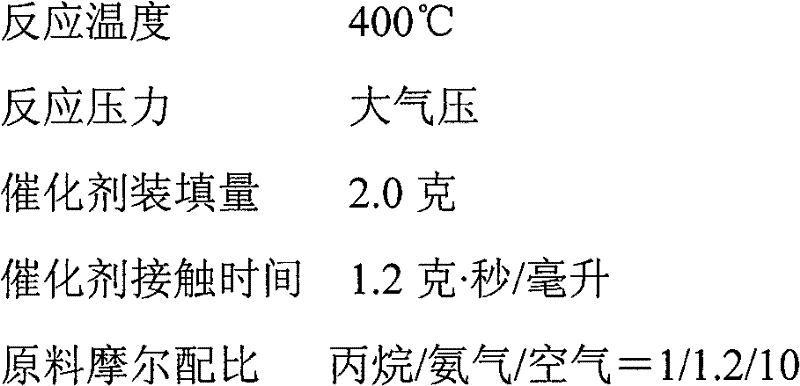

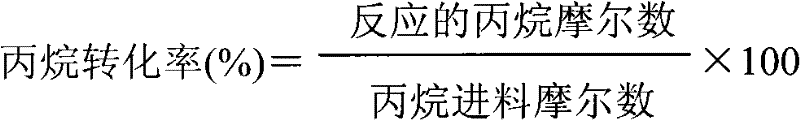

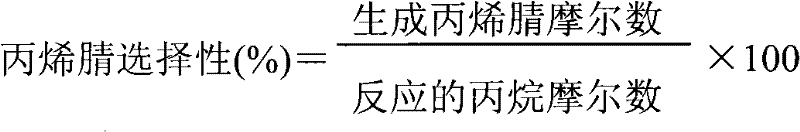

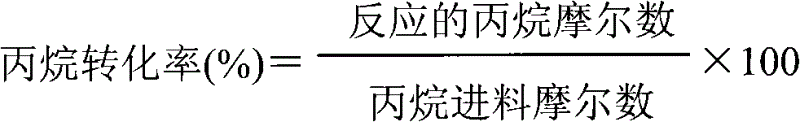

ActiveCN101279252ASimple compositionImprove stabilityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsAlkaneReaction temperature

The invention relates to a catalyst for alkane ammoxidation, which mainly aims at solving the problems of bad stability of the catalyst caused by that stibium requires circumfluence and Te is easy to volatilize in the prior art. Carrier containing silicon dioxide and atomic ratio are adopted to calculate the composition of general formula as MoVaNbbTecDdOx, wherein, D is at least one kind, which is selected from Sn, Ti, Fe, Bi, Sb or W; the preparation environment is changed by adjusting pH value by adding with acid in the process of preparation. Firstly the corresponding salt or oxide of Mo and Te is dissolved, then the solution of the corresponding salt or oxide of V and Nb is respectively added and acid with required amount is added for adjusting the pH value of the mixed solution, and at last silicasol with the required amount is added for preparing the catalyst. The technical proposal better solves the problems. The catalyst of the invention has the advantages of excellent stability of oxidation and reduction, low reaction temperature, clean reaction product and being capable of keeping higher yield for a long time, thus being suitable for preparing unsaturated nitriles with alkane ammoxidation in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

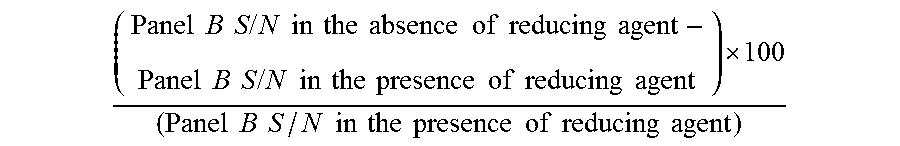

Tellurium containing alkane ammoxidation reaction catalyst

ActiveCN101306376AGood catalyst stabilitySimple compositionPhysical/chemical process catalystsPreparation by hydrocarbon ammoxidationChemistryHydrothermal synthesis

The invention relates to an oxidation reaction catalyst of telluriferous alkane ammonia, which comprises a silicon dioxide carrier and a combination which is calculated according to the atomic ratio and comprises the following general formula: MovaNbbTecDdOx, wherein D is at least one selected form Sn, Ti, Fe, Bi, Sb or W. The oxidation reaction catalyst mainly solves the problems that Te is easy to volatilize, the preparation technology is complex, the preparation environment is unstable, and the active component of the catalyst is easy to volatilize, thereby resulting in bad stability of the catalyst in the prior art; and the oxidation reaction catalyst better solves the problems through adopting the technical proposal that Mo-V-Nb-Te base is used as the main component, the hydrothermal synthesis method is adopted, the preparation environment is changed through adding reducing agent and acid during the preparation process, that is, firstly the solution of the corresponding salt or the corresponding oxide compound of Mo and Te is mixed with the solution of the corresponding salt or the corresponding oxide compound of V and Nb, then a specified volume of reducing agent and acid are added to adjust the pH value, and hydrothermal treatment is performed to the uniformly mixed solution. The catalyst has the advantages that the catalyst has good oxidation reduction stability, the reaction temperature is low, the reaction product is clean, and high yield coefficient can be kept for a long time, and the catalyst can be applied to the industrial production for the preparation of the unsaturated acid nitrile in the alkane ammonia oxidation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low temperature electrolyte using ethyl acetate as solvent

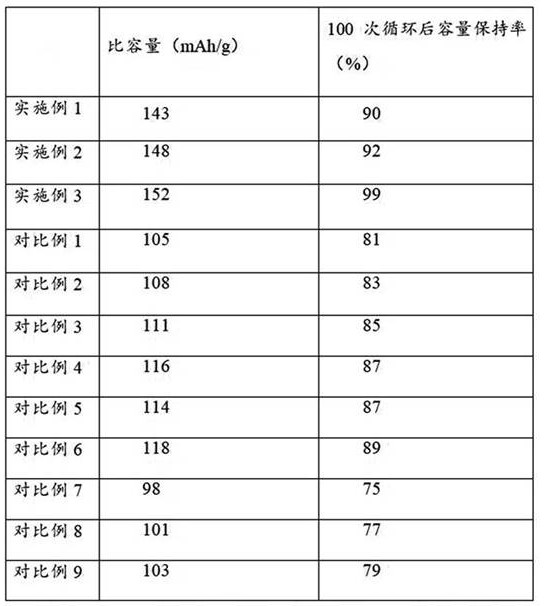

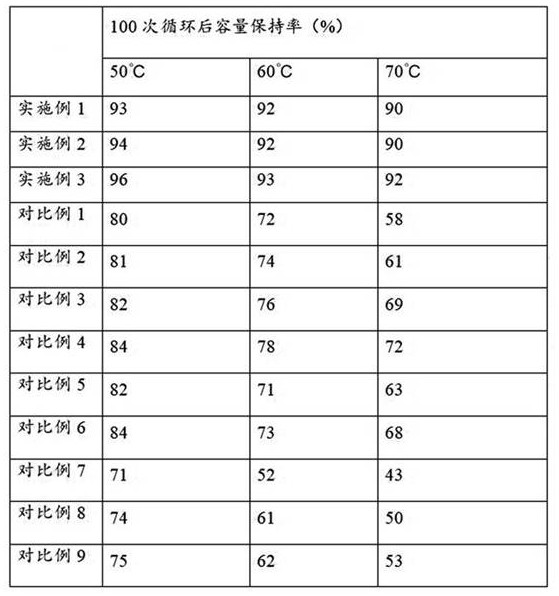

InactiveCN106169611ALow melting pointLow viscosityHybrid capacitor electrolytesSecondary cellsElectrolytic agentElectrical battery

The invention belongs to the field of electrochemical investigation, and specifically provides a low temperature electrolyte using ethyl acetate as a solvent. The low temperature electrolyte uses the ethyl acetate and derivate organic solvent as the solvent, and uses lithium salts, sodium salts or quaternary ammonium salts as a solute, and also comprises additives. The ethyl acetate has a very low melting point, and is still liquid in the low temperature environment of -83 DEG C. Compared with the traditional electrolyte, the low temperature electrolyte provided by the invention still has a high ionic conductivity at a low temperature of -80 DEG C. By applying the electrolyte provided by the invention to a lithium ion battery, a sodium-ion battery, a supercapacitor or a mixed type supercapacitor, the system is excellent in specific capacity, cycle performance and power performance.

Owner:FUDAN UNIV

Catalyst containing rare earth for ammoxidation of alkane

InactiveCN101797510ASimple compositionPromote oxidationPhysical/chemical process catalystsPreparation by hydrocarbon ammoxidationRare-earth elementAlkane

The invention relates to a catalyst containing rare earth for the ammoxidation of alkane, which contains a silicon dioxide carrier and a composition comprising the following general formula in atomic ratio: MoVaNbbTecDdEeOx, wherein D is selected from at least one of rare earth elements; and E is selected from one and a mixture of Ca, Sn, Ti, Fe, Bi, Sb or W. The invention mainly solves the problems of easily volatile Te, complex preparation process, instable preparation environment and poor catalyst stability caused by easily volatile active components of the catalyst existing in the prior art. In the invention, Mo-V-Nb-Te base is used as a main component of the catalyst, and a reducing agent and acid are added during preparation to change the preparation environment, i.e. the preparation process comprises the following steps of: firstly, dissolving corresponding salts or oxides of Mo and Te; then, respectively adding solutions of the corresponding salts or oxides of V, Nb and rare earth elements; subsequently, adding a certain amount of reducing agent and acid to regulate the pH value; and finally, adding a certain amount of silica sol. The catalyst has excellent oxidation reduction stability, low reaction temperature and high product yield, and can be applied to the industrial production of preparing unsaturated nitriles by the ammoxidation of the alkane.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing antimony-containing catalyst used for ammoxidation of alkane

ActiveCN101884918AImprove stabilityImprove performanceCatalyst activation/preparationPreparation by hydrocarbon ammoxidationAlkaneAdditive ingredient

The invention relates to a method for preparing an antimony-containing catalyst used for ammoxidation of alkane, which mainly solves the problem of poor stability of the catalyst due to difficult stable combination between Sb and Mo, complex preparation process, unstable preparation environment and easy volatilization of active ingredients of the catalyst existing in the prior art. In the method, the Mo-V-Nb-Sb base is used as a main ingredient of the catalyst, and a silica carrier and a composition including the MoVaNbbSbcDdOx general formula based on an atomic ratio are contained, wherein D is one of Sn, Ti, Fe, Bi, Te and W. The preparation environment is changed by dissolving corresponding salts or oxides of Mo and Sb; then respectively adding the solution of the corresponding salts or the oxides of V and Nb into the mixture; adding a proper amount of reducing agent into the mixture; and finally adding silica sol into the mixture. The technical scheme adopting a two-stage calcination mode can better solve the problem. The method can be applied to industrial production of unsaturated nitriles by using ammoxidation of alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalysts for the ammoxidation of alkanes

ActiveCN101428230AOvercome the problem of poor stabilityExcellent redox stabilityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsAlkaneOxidation state

The invention provides a catalyst for ammoxidation of alkanes. The catalyst contains silicon dioxide carrier and a composite compound of the following formula in atomic ratio: MoVaNbTe<c>DdOx, wherein D is at least one selected from Sn, Ti, Fe, Bi, Sb and W. The catalyst mainly solves the problems of volatilization loss of Te, complicated preparation process, unstable production environment and poor catalyst stability due to volatilization of active components of the catalyst. In order to solve the problems in the prior art, the technical scheme is as follows: the catalyst contains a Mo-V-Nb-Te group as a major component; and a reducer is added in the preparation process to change the preparation environment, that is, the salts or the oxides of Mo and Te are dissolved firstly, then the salts or the oxides of V and Nb are added in the resulting solution, the required amount of the reducer is added to adjust the oxidation state, and finally the required amount of the silica sol is added. The catalyst has the advantages of excellent oxidation-reduction stability, low reaction temperature, clean reaction product and high yield, and is applied to the industrial production of unsaturated nitrile via ammoxidation of alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

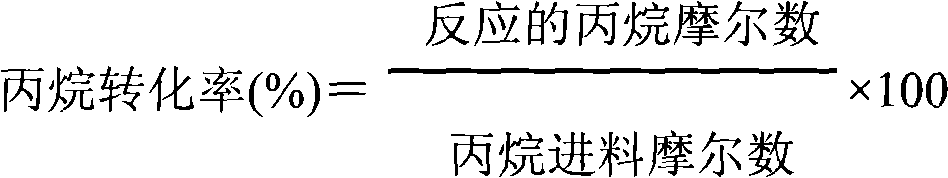

Method for preparing catalyst for alkane ammonia oxidation reaction

ActiveCN101992107AOvercoming problems such as poor stabilityEasy to shapeCatalyst activation/preparationPreparation by hydrocarbon ammoxidationAlkaneOxidation state

The invention relates to a method for preparing a catalyst for alkane ammonia oxidation reaction, which mainly solves the problems that the catalyst is formed nonuniformly, Te is volatile, the preparation technology is complex, the preparation environment is unstable, and active ingredients of the catalyst are volatile so as to cause low stability of the catalyst. A Mo-V-Nb-Te or Sb base is taken as a main component of the catalyst, and the catalyst comprises a silicon dioxide carrier and a composition with a general formula of MoVaNbbCcDdOx in an atomic ratio, wherein C is at least one of Te or Sb, and D is one of Sn, Ti, Fe, Bi, Al or W. A spray drying method is adopted, and the problems are solved by a technical scheme that a reducing agent is added in the preparation process to change the preparation environment, namely corresponding salt or oxides of Mo, Te or Sb are dissolved, solution of corresponding salt or oxides of V and Nb is respectively added, a needed amount of reducing agent is added to regulate an oxidation state, and a needed amount of silica sol is added for performing spray drying. The method can be applied to industrial production of preparing unsaturated nitriles by alkane ammonia oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

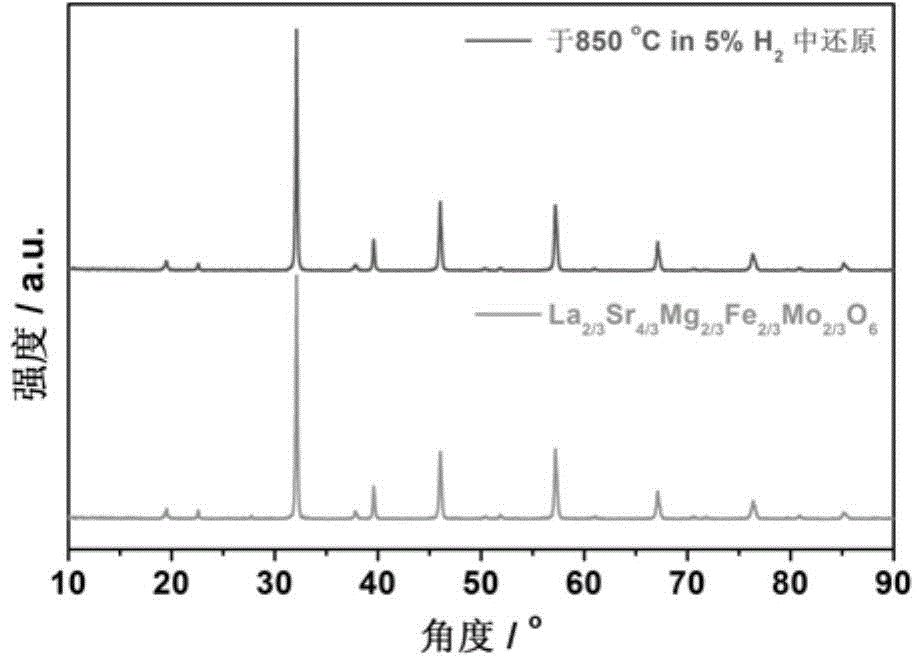

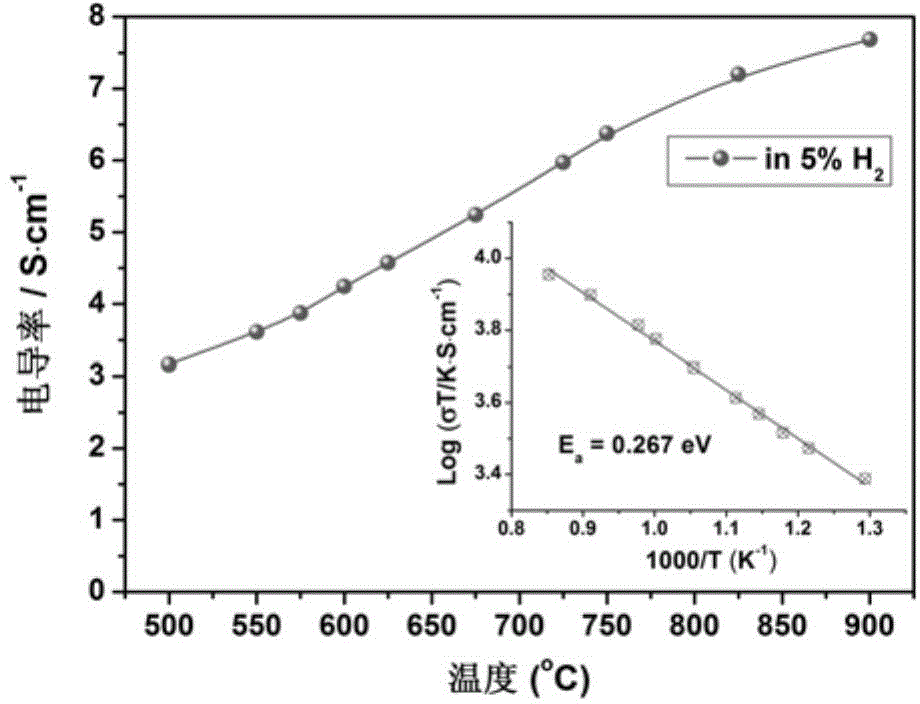

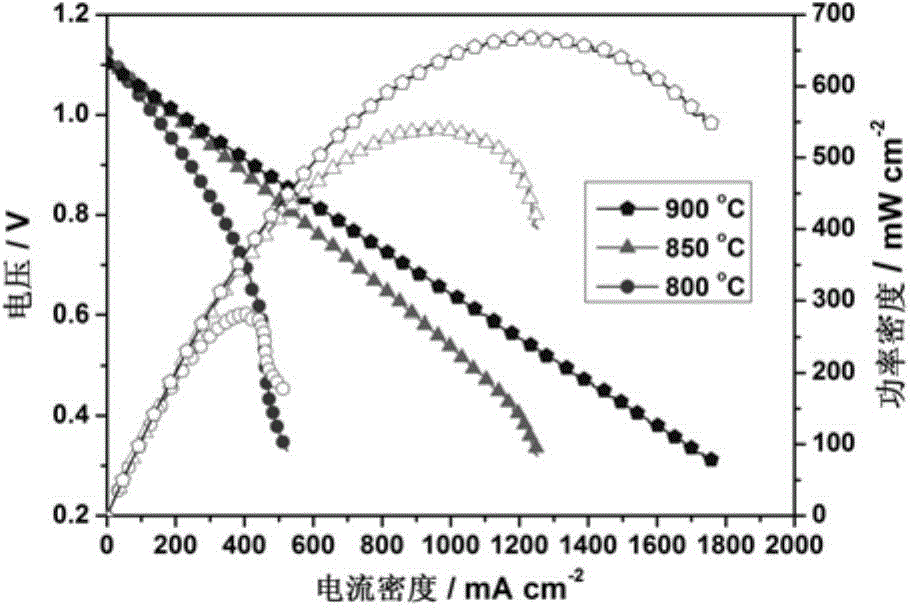

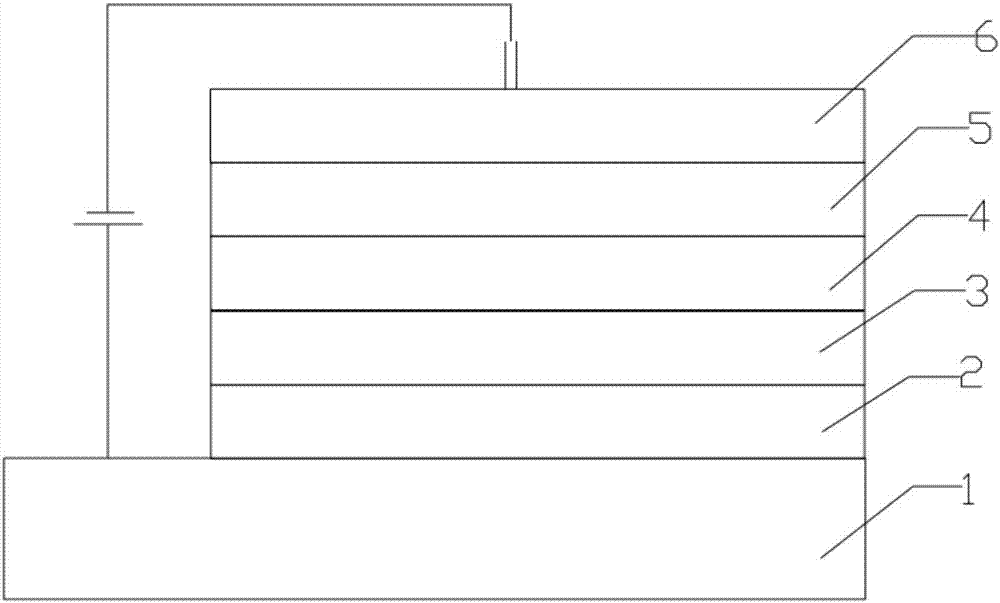

Double-perovskite-type anode material and preparation method thereof

ActiveCN104157881AExcellent redox stabilityLow costCell electrodesElectrical conductorMixed conductor

The invention discloses a double-perovskite-type anode material and a preparation method thereof, and belongs to the technical field of solid oxide fuel batteries. The site Mg and the site Mo of the anode material LaxSr(2-x)MgMoO6 of a double-perovskite (A2BB'O6) solid oxide fuel battery are simultaneously doped with Fe, so that a high-performance and high-stability double-perovskite structured blended conductor material is formed. The molecular formula of the double-perovskite-type anode material is LaxSr(2-x)Mg(1-y)Fe2yMo(1-y)O(6-delta), wherein x is greater than 0 and smaller than 1, y is greater than 0 and smaller than 1, and delta is greater than or equal to 0 and smaller than or equal to 1. The invention also discloses a compact-type anode material and a porous film anode material. The double-perovskite-type anode material has the technical effects that according to a charge compensation principle, the site Mg and the site Mo are simultaneously doped with Fe to achieve charge self-consistency of a material system, so that the redox stability of the material is effectively improved; cheap Fe is selected as a doping element, so that the cost of the material can be lowered; meanwhile, Fe is relatively high in valence change capacity, so that an effective conductive network can be formed on the site B, and the catalysis activity and the conductivity of the material are improved favorably.

Owner:UNIV OF SCI & TECH BEIJING

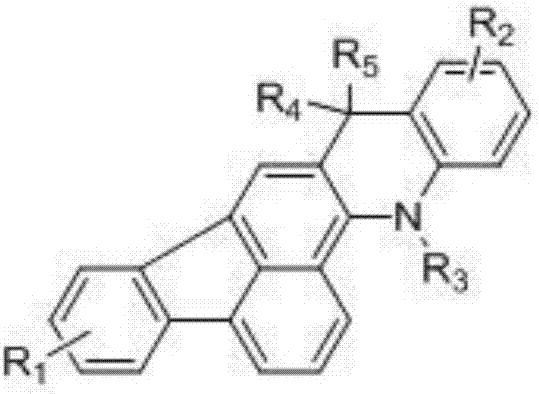

Novel organic electroluminescent material of fluoranthene and acridine type, and preparation method and application thereof

InactiveCN107353249ANot easy to crystallizeNot easy to gatherOrganic chemistrySolid-state devicesAcridineChemical compound

The invention belongs to the field of organic electroluminescence, and particularly relates to a novel organic electroluminescent material of fluoranthene and acridine type, and a preparation method and application thereof. The novel organic electroluminescent material is not easy to crystallize and not easy to aggregate among molecules, has proper molecular weight, good thin film stability, and suitable HOMO and LUMO energy levels; the material can be used as a luminescent layer of OLED devices and applied in the field of organic electroluminescence. When the compound is used as the luminescent layer material of OLED luminescent devices, the prepared OLED device has excellent photoelectric performance, and the device efficiency and the service life are increased.

Owner:VALIANT CO LTD

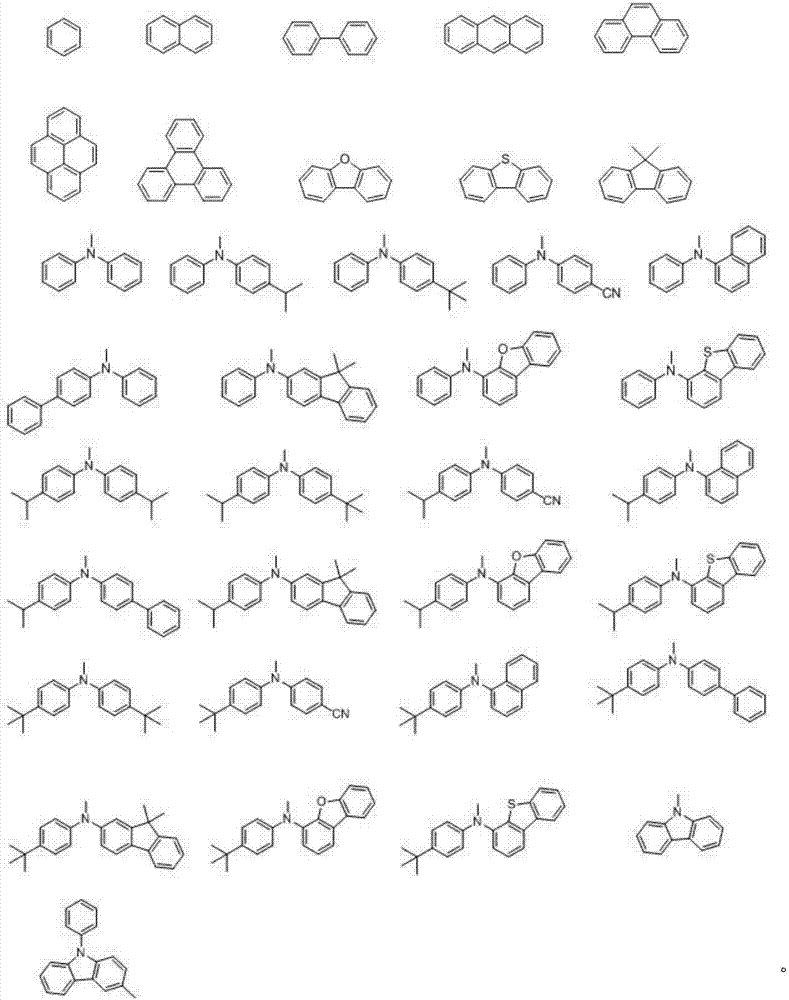

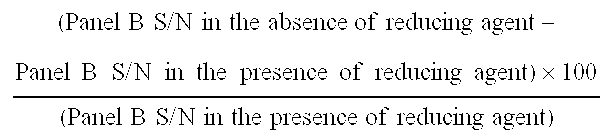

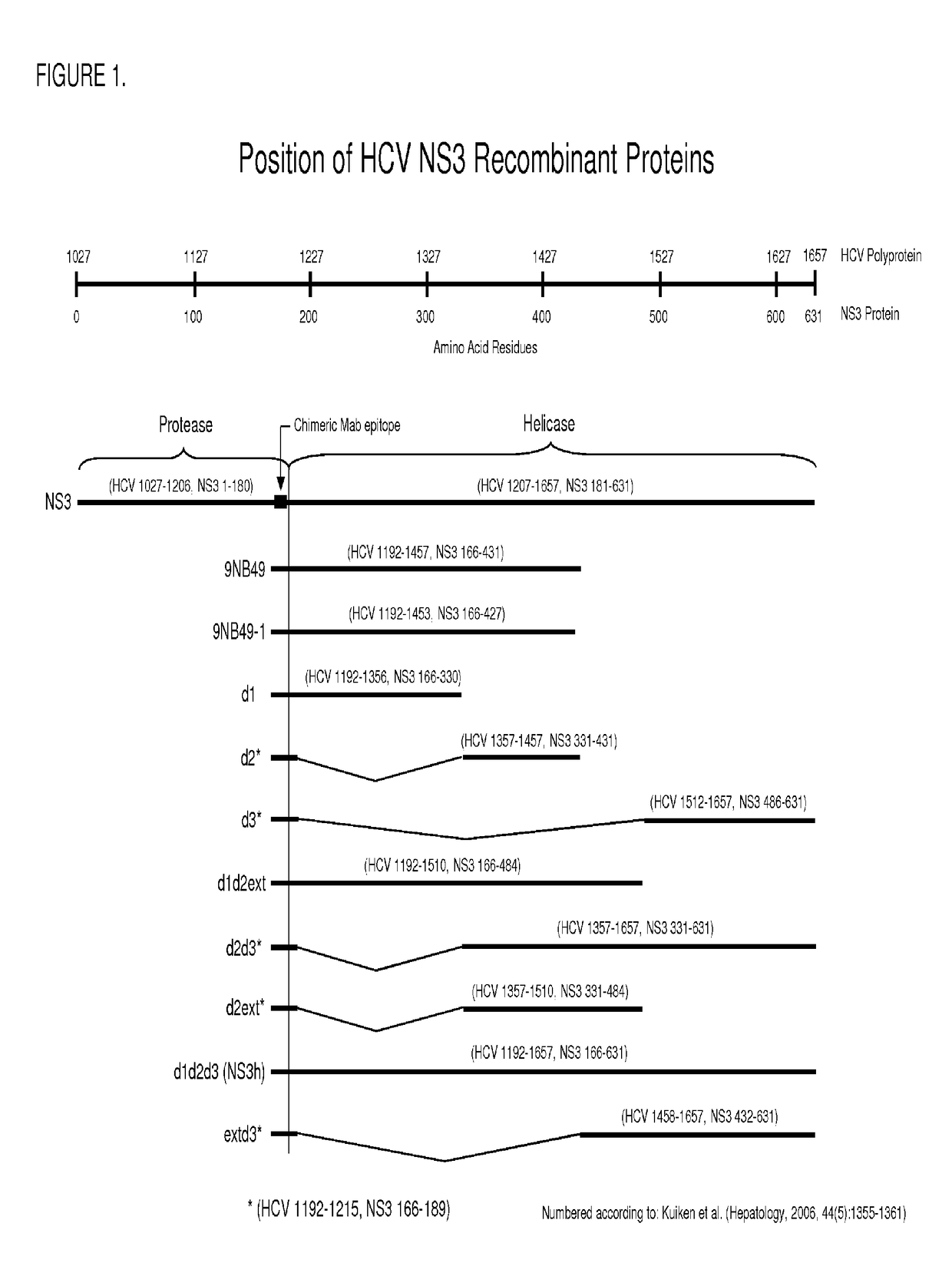

HCV NS3 recombinant antigens and mutants thereof for improved antibody detection

ActiveUS9790478B2Excellent redox stabilityStimulate immune responseSsRNA viruses positive-senseHydrolasesAnti hcv antibodyHCV Antibody

Owner:ABBOTT LAB INC

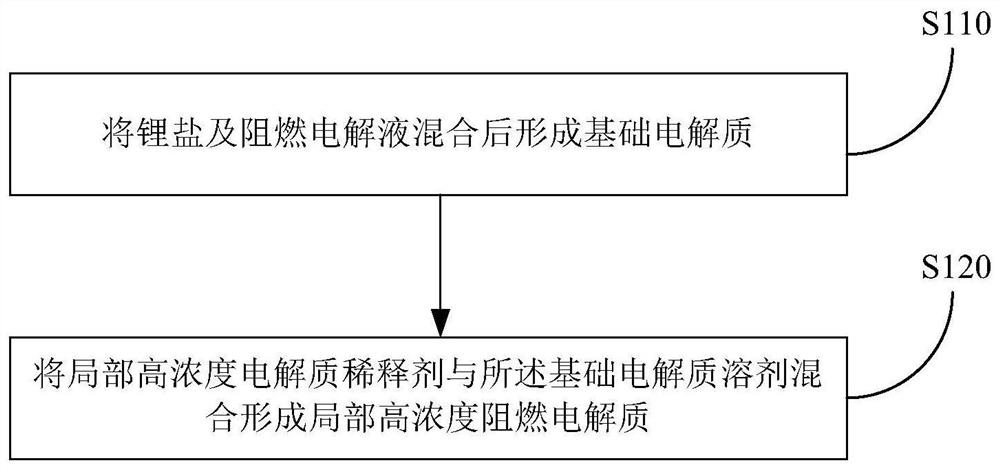

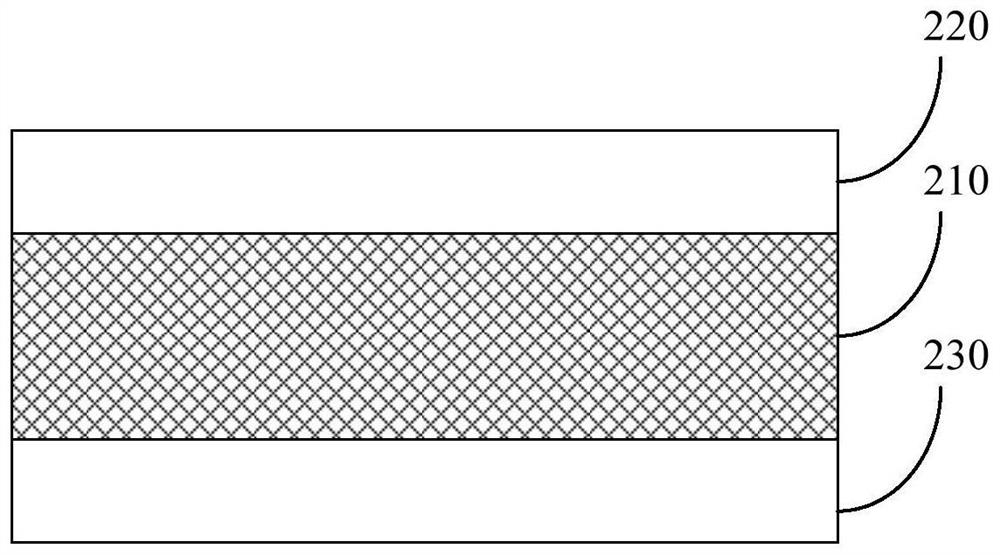

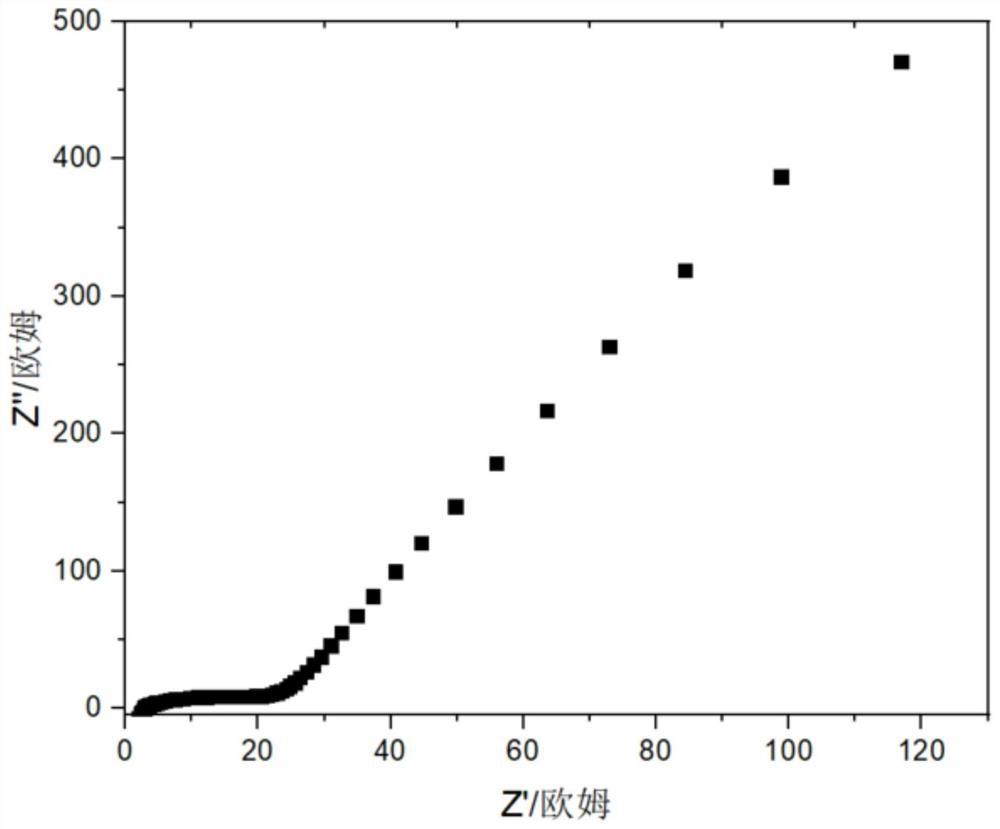

Local high-concentration flame-retardant electrolyte, lithium battery and preparation method of lithium battery

InactiveCN111668540AImprove flame retardant performanceWide variety of sourcesSolid electrolytesFinal product manufactureElectrolytic agentLithium metal

The invention provides a local high-concentration flame-retardant electrolyte. A lithium salt and a flame-retardant electrolyte are mixed to form a basic electrolyte; a local high-concentration electrolyte diluent and the basic electrolyte solvent are fixed to form a local high-concentration flame-retardant electrolyte, by adopting the local high-concentration flame-retardant electrolyte, the flame retardance of the electrolyte can be effectively improved, the coulombic efficiency is high under the current density of 1mAh cm<-2>, the electrolyte can be stably circulated for 125 circles, and the local high-concentration flame-retardant electrolyte is simple in preparation process, wide in raw material source, low in cost and suitable for industrial production. The local high-concentration flame-retardant electrolyte can be used for preparing a lithium battery, the oxidation-reduction stability of the electrolyte can be improved, the viscosity of the electrolyte is reduced, and the electrolyte is stable to lithium metal.

Owner:SHENZHEN INST OF ADVANCED TECH

HCV NS3 recombinant antigens and mutants thereof for improved antibody detection

InactiveUS20170327803A1Excellent redox stabilityStimulate immune responseSsRNA viruses positive-senseHydrolasesAnti hcv antibodyHCV Antibody

Owner:ABBOTT LAB INC

Catalysts for the ammoxidation of alkanes

ActiveCN101428230BOvercome the problem of poor stabilityExcellent redox stabilityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsAlkaneOxidation state

The invention provides a catalyst for ammoxidation of alkanes. The catalyst contains silicon dioxide carrier and a composite compound of the following formula in atomic ratio: MoVaNbTe<c>DdOx, wherein D is at least one selected from Sn, Ti, Fe, Bi, Sb and W. The catalyst mainly solves the problems of volatilization loss of Te, complicated preparation process, unstable production environment and poor catalyst stability due to volatilization of active components of the catalyst. In order to solve the problems in the prior art, the technical scheme is as follows: the catalyst contains a Mo-V-Nb-Te group as a major component; and a reducer is added in the preparation process to change the preparation environment, that is, the salts or the oxides of Mo and Te are dissolved firstly, then thesalts or the oxides of V and Nb are added in the resulting solution, the required amount of the reducer is added to adjust the oxidation state, and finally the required amount of the silica sol is added. The catalyst has the advantages of excellent oxidation-reduction stability, low reaction temperature, clean reaction product and high yield, and is applied to the industrial production of unsaturated nitrile via ammoxidation of alkanes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ceria and strontium titanate based electrodes

InactiveUS8945793B2Improve electrochemical activityLower resistanceFuel cells groupingActive material electrodesStrontium titanium oxideNiobium

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

Anode for an electrochemical cell and method for producing an electrochemical cell comprising such an anode

ActiveUS11133510B2Improve electrochemical stabilityExcellent redox stabilityCell electrodesFuel cellsHydrogen atmosphereElectrochemical cell

The invention relates to an electrode for an electrochemical cell, wherein an electrode is flatly applied onto a surface of a solid oxide electrolyte, and a cathode is flatly applied onto the solid oxide electrolyte surface opposite the electrode. The base material of the electrode is a composite whose catalytically active metal component contains a nickel phase which is made of NiO as part of the electrode starting material by reducing the NiO in a hydrogen-containing atmosphere. The ceramic component is made with a doped cerium oxide and a spinel made of at least one transition metal selected from Ni, Mn, Fe, and Cr.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

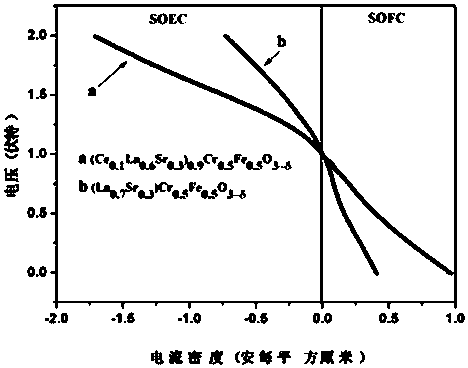

CO2 high-temperature electrolysis electrolytic tank cathode material and preparation method thereof

ActiveCN109487299AIncreased oxygen vacancy contentIncreased oxygen hole concentrationIron compoundsElectrode shape/formsNitrateFuel cells

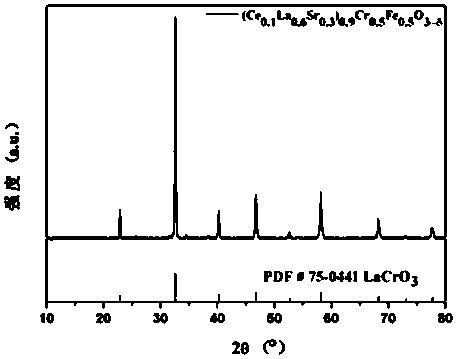

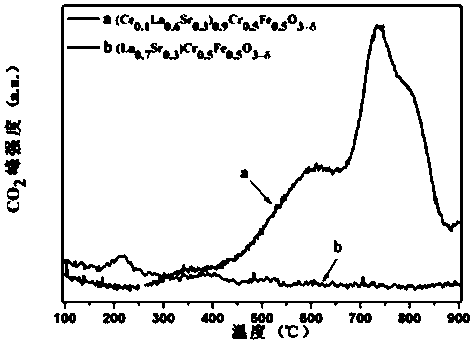

The invention discloses a CO2 high-temperature electrolysis electrolytic tank cathode material and a preparation method thereof and belongs to the field of energy and fuel batteries. The properties ofCO2 electrolysis of a perovskite material are improved, an A-position defect and a cerium atom are doped into an A position of a perovskite type AA'BB'O3-delta material, then an A-position defect-cerium atom doped perovskite material is formed, nitrate of Ce and nitrates of metals contained in an A position, an A' position, a B position and a B' position are dissolved in deionized water, then glycine is added, a mixed solution is obtained, and then the mixed solution is stirred at 50-95 DEG C so as to form gel; the obtained gel is heated to burn, a product obtaining through burning is ground,and then burnt powder is obtained; the burnt powder is pre-burnt, and pre-burnt powder is obtained; and the pre-burnt powder is subjected to high-temperature calcining, and the CO2 high-temperature electrolysis cathode material is obtained. The cathode material serves as an electrode, and YSZ serves as an electrolyte, so that assembled symmetrical batteries are excellent in CO2 electrolysis property.

Owner:SHANXI UNIV

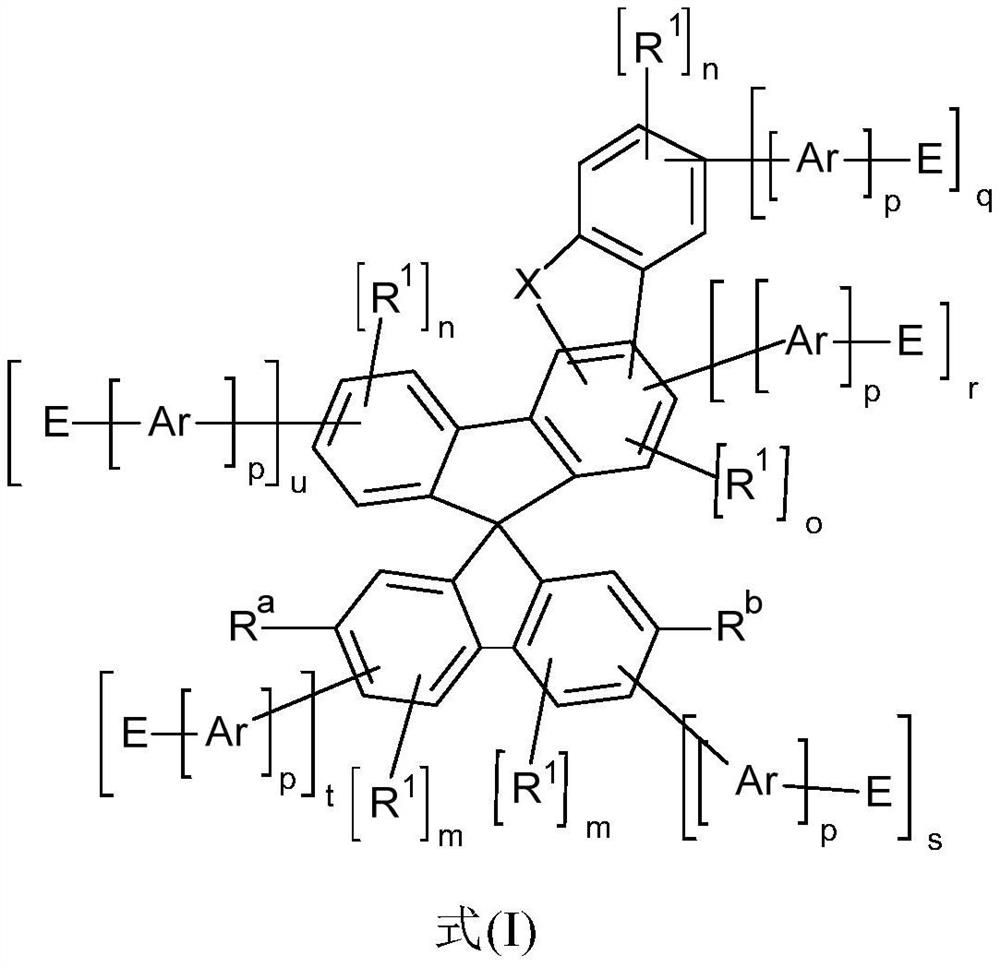

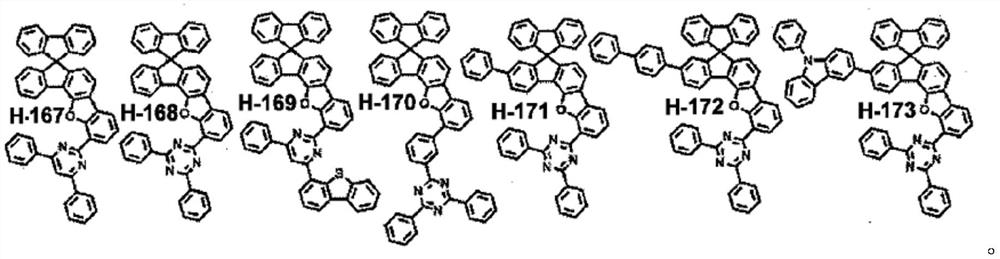

Heterocyclic spiro compounds

PendingCN112851613AExcellent lifeHigh redox stabilityIndium organic compoundsGroup 5/15 element organic compoundsOrganic electroluminescencePolymer chemistry

The invention relates to a heterocyclic spiro compound, in particular, the present invention relates to spiro compounds having electron-conducting groups and to electronic devices, in particular organic electroluminescent devices, containing said compounds.

Owner:MERCK PATENT GMBH

Method for preparing catalysts for ammoxidation of alkanes

ActiveCN101121125AHigh yieldGood repeatabilityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsAlkaneActive component

The present invention relates to a catalyst preparation method used for an alkane ammoxidation and mainly solves the problems in the prior art that the preparation technology is complex, such as Sb has to reflow etc; the preparation environment is not stable; an unsaturated nitrile yield is not high, and an active components of the catalyst is easy to valatilized. The present invention solves the problems well by a technical proposal that V-Sb-Al base is adopted as the main component; acid is added during the process of preparation to change the preparation environment and adjust the pH value, that is firstly V and relevant auxiliary metal salt or oxide are made into the solution, then relevant salt or oxide of Sb is directly added into the above solution in stirring, and the relevant quantity of salt or oxide of Al is added, and finally the acid solution is added to adjust the pH value to be 1 to 5. The present invention can be used for the industrial production of the alkane ammoxidation for producing the unsaturated nitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for acrylonitrile production

PendingCN113828324AHigh activityReduce the temperaturePreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses a catalyst for acrylonitrile production, relates to the technical field of catalysts for chemical production, and particularly relates to a catalyst for acrylonitrile production. The catalyst is characterized by comprising a compound of a basic body containing iron, bismuth, molybdenum, magnesium and carbon, an optional catalytic oxide containing one or more elements of lithium, sodium, potassium, rubidium, cesium, cobalt, nickel, strontium, manganese, calcium, barium, phosphorus, boron, antimony, chromium, tungsten and vanadium, and a catalyst carrier, and the general formula of the catalyst is AaBbMgcFedCeBifMogOx. According to the catalyst for acrylonitrile production, basic bodies of iron, bismuth, molybdenum, magnesium and carbon are arranged in the catalyst, and one or more of active elements of lithium, sodium, potassium, rubidium, barium, phosphorus, boron and the like are added in the catalyst, so that the overall activity of the catalyst is improved, the temperature and pressure required by the reaction of the catalyst are reduced, and the limitation on production equipment is reduced; therefore, the preparation cost is reduced, the temperature and pressure required by the reaction are reduced, and the safety during production is improved.

Owner:黑龙江省君鑫化工有限公司

Tellurium containing alkane ammoxidation reaction catalyst

ActiveCN101306376BOvercome the problem of poor stabilityExcellent redox stabilityPhysical/chemical process catalystsPreparation by hydrocarbon ammoxidationAlkaneReaction temperature

The invention relates to an oxidation reaction catalyst of telluriferous alkane ammonia, which comprises a silicon dioxide carrier and a combination which is calculated according to the atomic ratio and comprises the following general formula: MovaNbbTecDdOx, wherein D is at least one selected form Sn, Ti, Fe, Bi, Sb or W. The oxidation reaction catalyst mainly solves the problems that Te is easyto volatilize, the preparation technology is complex, the preparation environment is unstable, and the active component of the catalyst is easy to volatilize, thereby resulting in bad stability of thecatalyst in the prior art; and the oxidation reaction catalyst better solves the problems through adopting the technical proposal that Mo-V-Nb-Te base is used as the main component, the hydrothermalsynthesis method is adopted, the preparation environment is changed through adding reducing agent and acid during the preparation process, that is, firstly the solution of the corresponding salt or the corresponding oxide compound of Mo and Te is mixed with the solution of the corresponding salt or the corresponding oxide compound of V and Nb, then a specified volume of reducing agent and acid areadded to adjust the pH value, and hydrothermal treatment is performed to the uniformly mixed solution. The catalyst has the advantages that the catalyst has good oxidation reduction stability, the reaction temperature is low, the reaction product is clean, and high yield coefficient can be kept for a long time, and the catalyst can be applied to the industrial production for the preparation of the unsaturated acid nitrile in the alkane ammonia oxidation reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Triptycene-centered methoxytriphenylamine-containing polyamide as well as a preparation method and application thereof

ActiveCN113444242AImprove stabilityImprove solubilityPhotovoltaic energy generationNon-linear opticsPolymer sciencePolyamide

The invention discloses triptycene-centered methoxytriphenylamine-containing polyamide as well as a preparation method and the application thereof, and relates to triptycene-centered methoxytriphenylamine-containing polyamide as well as a preparation method and the application thereof. In order to solve the problems of low solubility, no electrochromism performance and narrow application range of triptycene caused by overlarge rigidity of triptycene in an organic solvent, the invention provides a triptycene-centered methoxytriphenylamine-containing polymer as well as a preparation method and the application thereof in electrochromism. According to the invention, triiodo-triptycene is used as a raw material and is subjected to a substitution reaction with 4-methoxy-4 '-nitrodiphenylamine to generate a triptycene-centered methoxy-containing triphenylamine monomer. A diacid monomer is reacted with a triptycene-centered methoxyl-containing triphenylamine monomer to generate the triptycene-centered methoxyl-containing triphenylamine polymer. The method is applied to the field of electrochromism.

Owner:HEILONGJIANG UNIV

Method for preparing antimony-containing catalyst used for ammoxidation of alkane

ActiveCN101884918BOvercoming problems such as poor stabilityExcellent redox stabilityCatalyst activation/preparationPreparation by hydrocarbon ammoxidationAlkaneAdditive ingredient

The invention relates to a method for preparing an antimony-containing catalyst used for ammoxidation of alkane, which mainly solves the problem of poor stability of the catalyst due to difficult stable combination between Sb and Mo, complex preparation process, unstable preparation environment and easy volatilization of active ingredients of the catalyst existing in the prior art. In the method,the Mo-V-Nb-Sb base is used as a main ingredient of the catalyst, and a silica carrier and a composition including the MoVaNbbSbcDdOx general formula based on an atomic ratio are contained, wherein Dis one of Sn, Ti, Fe, Bi, Te and W. The preparation environment is changed by dissolving corresponding salts or oxides of Mo and Sb; then respectively adding the solution of the corresponding salts or the oxides of V and Nb into the mixture; adding a proper amount of reducing agent into the mixture; and finally adding silica sol into the mixture. The technical scheme adopting a two-stage calcination mode can better solve the problem. The method can be applied to industrial production of unsaturated nitriles by using ammoxidation of alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst for alkane ammonia oxidation reaction

ActiveCN101992107BOvercoming problems such as poor stabilityEasy to shapeCatalyst activation/preparationPreparation by hydrocarbon ammoxidationAlkaneOxidation state

The invention relates to a method for preparing a catalyst for alkane ammonia oxidation reaction, which mainly solves the problems that the catalyst is formed nonuniformly, Te is volatile, the preparation technology is complex, the preparation environment is unstable, and active ingredients of the catalyst are volatile so as to cause low stability of the catalyst. A Mo-V-Nb-Te or Sb base is takenas a main component of the catalyst, and the catalyst comprises a silicon dioxide carrier and a composition with a general formula of MoVaNbbCcDdOx in an atomic ratio, wherein C is at least one of Teor Sb, and D is one of Sn, Ti, Fe, Bi, Al or W. A spray drying method is adopted, and the problems are solved by a technical scheme that a reducing agent is added in the preparation process to changethe preparation environment, namely corresponding salt or oxides of Mo, Te or Sb are dissolved, solution of corresponding salt or oxides of V and Nb is respectively added, a needed amount of reducingagent is added to regulate an oxidation state, and a needed amount of silica sol is added for performing spray drying. The method can be applied to industrial production of preparing unsaturated nitriles by alkane ammonia oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound, charge transporting material and organic electroluminescent element

ActiveCN100586244CExcellent redox stabilityImprove performanceOrganic chemistryElectrical apparatusOrganic electroluminescencePyridine

A charge transport material exhibiting excellent thermal stability, film forming capability, charge transport capability and luminescence characteristics; and an organic electroluminescent device of high luminance, high light emitting capability and prolonged operating life. There is provided a charge transport material comprising a compound containing two or more pyridine rings substituted at 2,4,6-positions in its molecule characterized in that the pyridine rings are substantially not conjugated with each other (provided that the pyridine rings may be optionally substituted at the 3,5-positions thereof), and further provided an organic electroluminescent device including the charge transport material.

Owner:MITSUBISHI RAYON CO LTD

Power type electrolyte and sodium ion battery

ActiveCN114725520AHigh dielectric constantImprove power performanceMaterial nanotechnologyHybrid capacitor electrolytesElectrolytic agentOrganic solvent

The invention discloses a power type electrolyte, an electrolyte salt, an organic solvent and a composite additive, the electrolyte salt is formed by compounding at least one weak coordination anion sodium salt with a large ion radius and a bentonite modifier according to a weight ratio of 3: 1, and the composite additive comprises fluoro-carbonate, sultone and modified alumina. Compared with the traditional electrolyte, the power type electrolyte disclosed by the invention shows relatively high ionic conductivity and relatively low sodium ion desolvation energy, and ensures that the sodium ion battery has excellent high-power performance. The sodium ion battery using the electrolyte shows an excellent capacity retention ratio under a high-rate charge-discharge working condition, and the cycle life of the battery during high-rate charge-discharge is prolonged.

Owner:南通全诺新能源材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com