Catalysts for the ammoxidation of alkanes

An oxidation reaction and catalyst technology, which is applied in the direction of hydrocarbon ammoxidation preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of poor catalyst stability, complicated preparation process, low yield No high problems, achieve good catalyst stability, good repeatability, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]15.0 grams of ammonium heptamolybdate and 4.46 grams of telluric acid are dissolved in 69.2 grams of hot water to make solution (I); 3.06 grams of ammonium metavanadate are dissolved in 60.0 grams of hot water to make solution (II); Dissolve 5.78 grams of niobium oxalate in 16.0 grams of hot water to make solution (III); dissolve 2.32 grams of oxalic acid in 5 grams of water to make solution (IV). Solution (I) is joined in the solution (II) under stirring, then add solution (III) and solution (IV) successively, finally add 50 grams of silica sols that weight concentration is 40%, make the slurry of catalyst, will The slurry was stirred and evaporated at 90°C until a viscous slurry was obtained, then dried, ground, and calcined in a nitrogen atmosphere at 600°C for 2 hours to obtain propane ammoxidation catalyst Mo 1 V 0.31 Nb 0.22 Te 0.23 o x +50% SiO2 2 After tableting, 20-40 meshes were taken for fixed-bed microreflective evaluation.

Embodiment 2~6 and comparative example 2~3

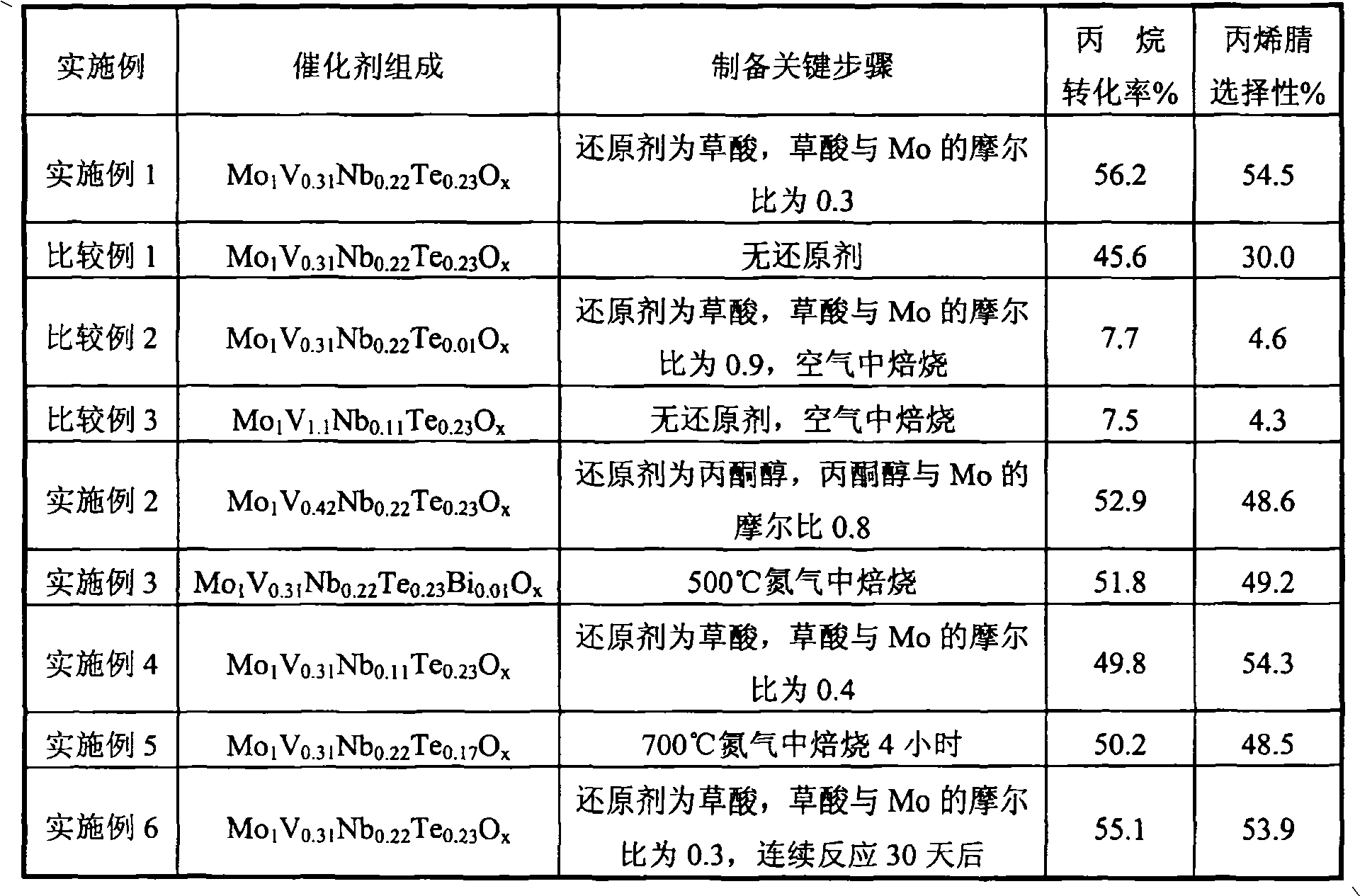

[0048] Catalysts with different compositions in the following table were prepared by the same method as in Example 1, and the ammoxidation of propane to acrylonitrile was carried out under the following reaction conditions with the prepared catalyst. See Table 1 for specific changes and results.

[0049] The reaction conditions of above-mentioned embodiment and comparative example are:

[0050] Fixed bed reactor with an inner diameter of 8 mm

[0051] Reaction temperature 405°C

[0052] Reaction pressure Atmospheric pressure

[0053] Catalyst loading 2.0 grams

[0054] Catalyst contact time 1.2 g·s / ml

[0055] Raw material ratio (mole) propane / ammonia / air=1 / 1.2 / 10

[0056] Table 1

[0057]

Embodiment 6

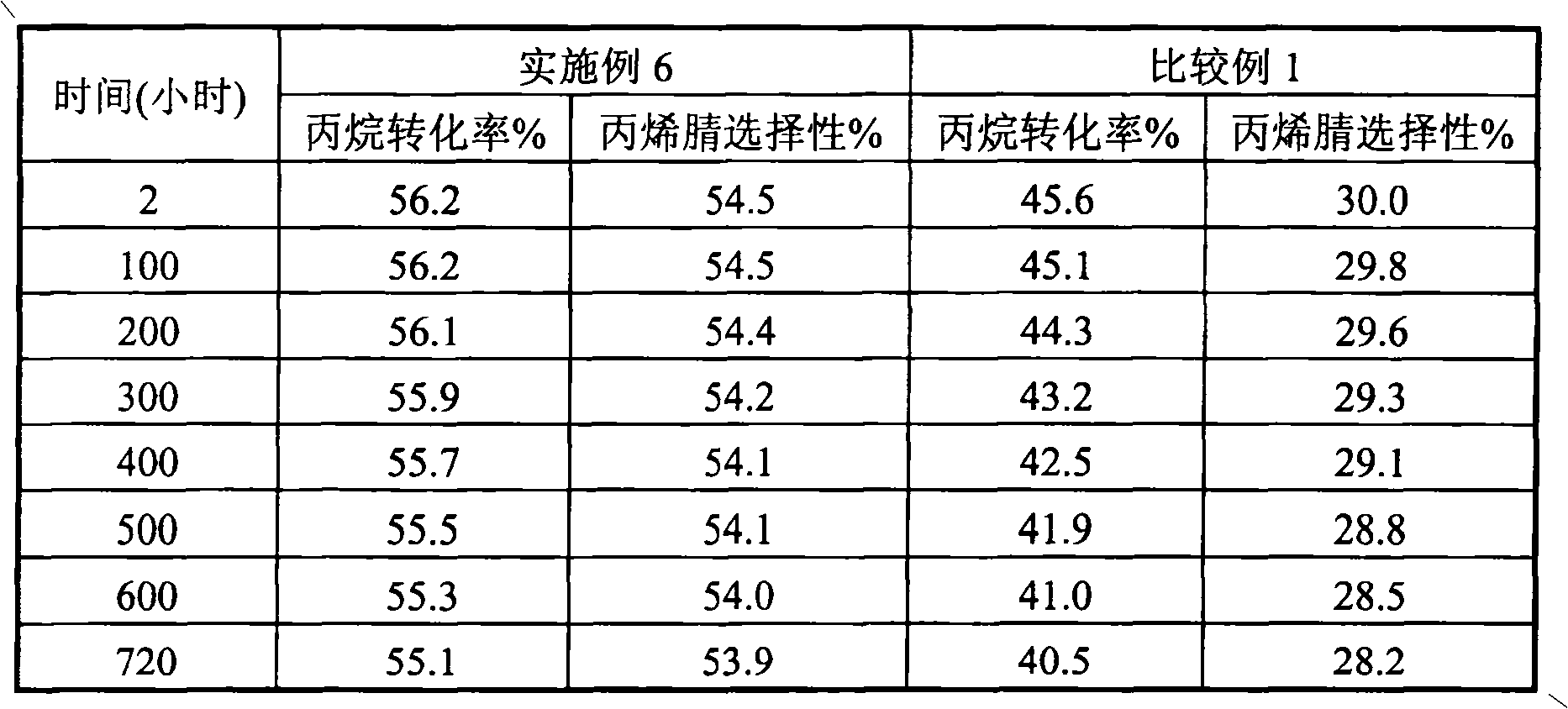

[0058] The stability evaluation result of embodiment 6 and comparative example 1 is shown in table 2

[0059] Table 2

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com