Local high-concentration flame-retardant electrolyte, lithium battery and preparation method of lithium battery

An electrolyte and high-concentration technology, used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, lithium batteries, etc., can solve the problems of low wettability of the diaphragm, high viscosity, and unstable negative electrode.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

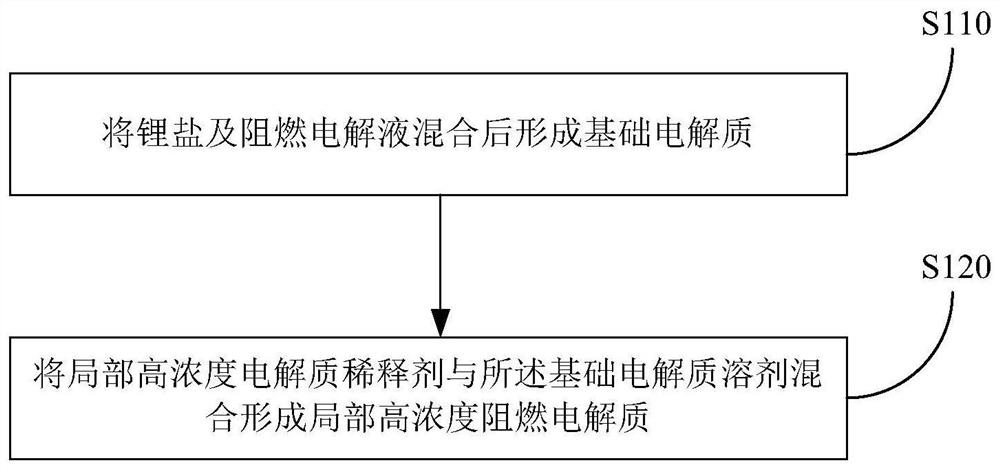

[0029] like figure 1 As shown, a method for preparing a local high-concentration flame-retardant electrolyte according to an embodiment, the preparation method for the local high-concentration flame-retardant electrolyte includes the following steps:

[0030] S110: A basic electrolyte is formed by mixing the lithium salt and the flame retardant electrolyte.

[0031] In some of these embodiments, the lithium salt is selected from lithium bis(fluorosulfonyl)imide (LiFSI), lithium bistrifluoromethanesulfonimide (LiTFSI), and lithium bisoxalatoborate (LiBOB). at least one.

[0032] It can be understood that high-quality lithium salts have a great impact on the energy density, power density, wide electrochemical window, cycle life, safety performance, etc. of lithium batteries. By selecting the above lithium salts, the energy density and power of lithium batteries can be improved. Density, wide electrochemical window, cycle life and safety performance.

[0033] In some embodimen...

Embodiment 1

[0052] The local high-concentration electrolyte provided by this embodiment includes the following components in a weight ratio: 84.24% of the base electrolyte, 15.76% of the base electrolyte formed by LiFSI, in the base electrolyte, the mole fraction of lithium bisfluorosulfonimide is 1 mol / L.

[0053] The preparation method of the local high-concentration electrolyte in this embodiment is as follows:

[0054] Dissolve 0.187 g of LiTFSI in 1 mL of TMP solution, and stir at room temperature for 0.5 h until the LiTFSI is completely dissolved to form a base electrolyte of high-concentration lithium salt. In the base electrolyte, the molar concentration of lithium bisfluorosulfonimide is is 1 mol / L.

[0055] 2 mL of HFE was added to the above basic electrolyte, and stirred at room temperature for 0.5 h until uniformly mixed to obtain a flame retardant electrolyte.

Embodiment 2

[0057] The local high-concentration electrolyte provided in this embodiment includes the following components in a weight ratio: 68.14% of the base electrolyte, 15.76% of the base electrolyte formed by LiTFSI, in the base electrolyte, the mole fraction of lithium bisfluorosulfonimide is 5mol / L.

[0058] The preparation method of the local high-concentration electrolyte in this embodiment is as follows:

[0059] Dissolve 0.935 g of LiTFSI in 1 mL of TTE solution, and stir at room temperature for 0.5 h until the LiTFSI is completely dissolved to form a base electrolyte of high-concentration lithium salt. In the base electrolyte, the molar concentration of LiTFSI is 5 mol / L.

[0060] 2 mL of TTE was added to the above basic electrolyte, and stirred at room temperature for 0.5 h until uniformly mixed to obtain a flame retardant electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com