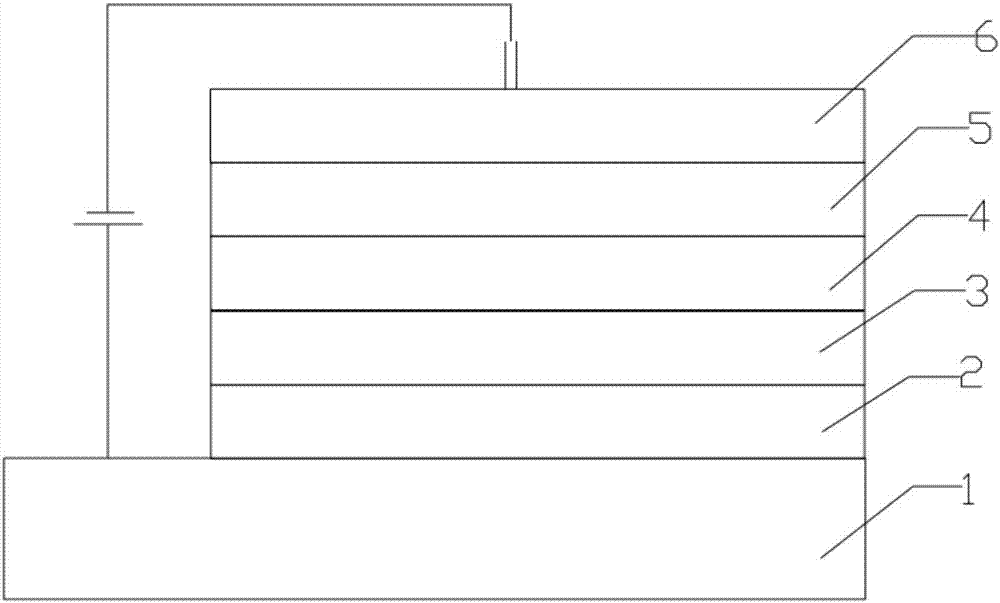

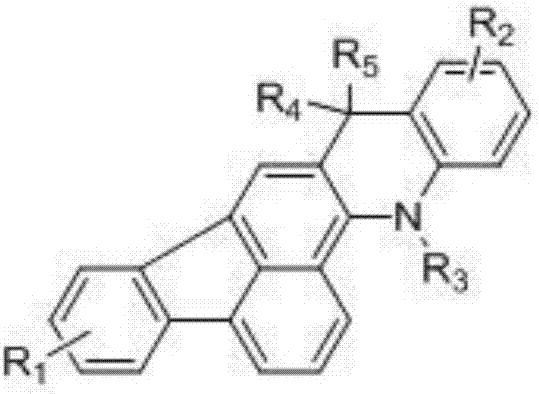

Novel organic electroluminescent material of fluoranthene and acridine type, and preparation method and application thereof

An electroluminescent material, acridine technology, applied in organic chemistry, circuits, electrical components, etc., can solve the problems of immature blue light-emitting devices, low device life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

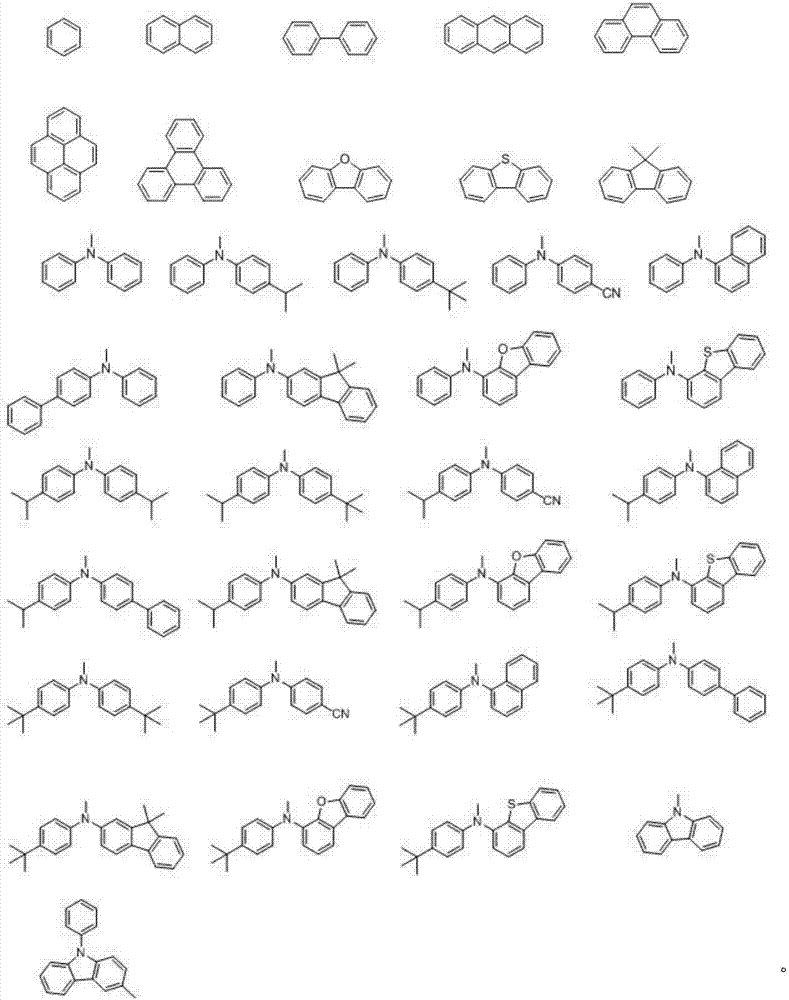

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of intermediate 1-IV, the reaction equation is as follows:

[0068]

[0069] (1) Preparation of intermediate 1-I: In a 1L three-necked flask, add 2-aminoacetophenone (33.8g, 0.25mol), 3,8-dibromofluoranthene (93.6g, 0.26mol), tert-butyl Sodium alkoxide (28.8g, 0.30mol), palladium acetate (0.56g, 2.5mmol), P(t-Bu) 3 HBF 4 (1.451g, 5mmol) and 500mL xylene, reacted at 120-130°C for 12h, after the reaction was completed, 100g of water was added to the reaction system to quench the reaction, filtered, the filtrate was decompressed to remove the solvent, purified by column chromatography, and then purified by toluene, Intermediate 1-I was obtained by recrystallization of petroleum ether with a yield of 74.61%;

[0070] (2) Preparation of intermediate 1-II: Add the above-mentioned intermediate 1-I (62.1g, 0.15mol) into a 1L three-necked flask, add 400g of tetrahydrofuran, cool down to -78°C, add methylmagnesium bromide dropwise Tetrahydrofuran solut...

Embodiment 2

[0075] Example 2 Preparation of intermediate 2-IV, the structural formula is:

[0076]

[0077] Referring to Example 1, in the preparation process, the raw material methylmagnesium bromide in step (2) was replaced with phenylmagnesium bromide to obtain intermediate 2-IV with a yield of 31.57%.

[0078] High resolution mass spectrometry, molecular formula C 41 h 26 BrN, theoretical value 611.1249, tested value 611.1213.

[0079] The intermediate 2-IV prepared in Example 2 was used as the reaction raw material of Examples 4 and 13-15.

Embodiment 3

[0080] Example 3 Preparation of intermediate 1-V, the reaction equation is as follows:

[0081]

[0082] In a 500mL three-necked flask, add intermediate 1-IV (24.4g, 0.05mol) and dichloroethane (250g), cool down to -5~0°C, slowly add bromine (9.6g, 0.06mol) dropwise, - Incubate at 5-0°C for 4 hours, add sodium sulfite solution to quench the reaction, separate liquid, wash with water, purify by column chromatography, and recrystallize from toluene to obtain intermediate 1-Ⅴ with a yield of 81.33%.

[0083] High resolution mass spectrometry, molecular formula C 31 h 21 Br 2 N, theoretical value 565.0041, test value 565.0079.

[0084] The intermediate 1-V prepared in Example 3 was used as the reaction raw material in Examples 10-12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com