CO2 high-temperature electrolysis electrolytic tank cathode material and preparation method thereof

A high-temperature electrolysis and cathode material technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of carbon deposition, reduced electrolysis performance, poor electrode stability, etc., and achieve the effect of excellent electrolysis performance and high redox stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

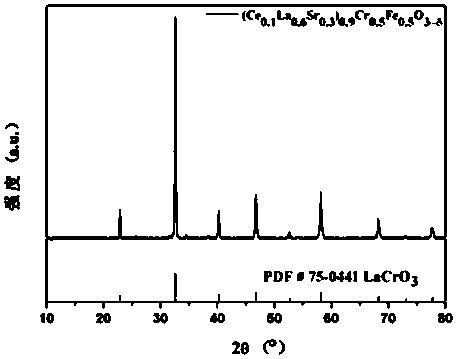

[0027] Synthesis (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ . The nitrates of Ce, La, Sr, Cr, Fe are dissolved in deionized water in proportion, and then glycine is added to keep the total molar ratio of glycine to all metal ions at 2.5:1. Then put the solution in a 70°C water bath to heat and evaporate for several hours to form a gel, and then put the gel in a 180°C constant temperature oven to heat to burn. After cooling, grind to obtain combustion powder. The burning powder is placed in an air atmosphere at 500° C. for pre-burning for 10 hours to remove the organic matter in the powder. Finally, it is calcined at 1300°C for 5 hours, and after grinding, the A-site defect-Ce atom co-doped perovskite high-temperature solid oxide electrolytic cathode material of the present invention is obtained. figure 1 Is the product (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ XRD pattern. It can be seen from the figure that the present invention has successfully prepared pure per...

Embodiment 2

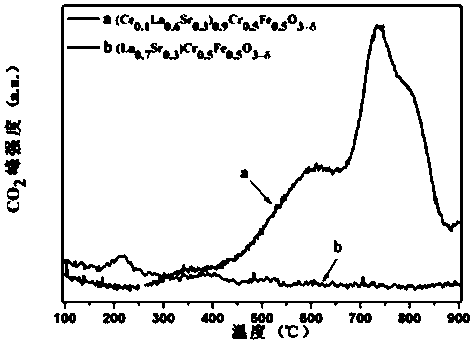

[0029] Cathode material (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ CO 2 -TPD Research (CO 2 Temperature programmed desorption), and attached with (La 0.7 Sr 0.3 )Cr 0.5 Fe 0.5 O 3-δ (STO-LSCrF) Comparison of electrodes. Use CO 2 -TPD to test material desorption CO 2 Ability. First reduce the sample at 850℃ in hydrogen atmosphere for 2h, protect it with argon to 400℃, and then in CO 2 Treated under the atmosphere for 1h. The sample after cooling treatment is temperature-programmed for desorption under argon. The argon flow rate is 20 ml / min [STP], the starting temperature is 100°C, the ending temperature is 900°C, and the heating rate is 10°C / min. Real-time monitoring of CO in exhaust gas with online mass spectrometer 2 . figure 2 For (La 0.7 Sr 0.3 )Cr 0.5 Fe 0.5 O 3-δ And (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ CO 2 -TPD curve, it can be found from the figure that without A-site defects and Ce doped (La 0.7 Sr 0.3 )Cr 0.5 Fe 0.5 O 3-δ The desorption starts at 200...

Embodiment 3

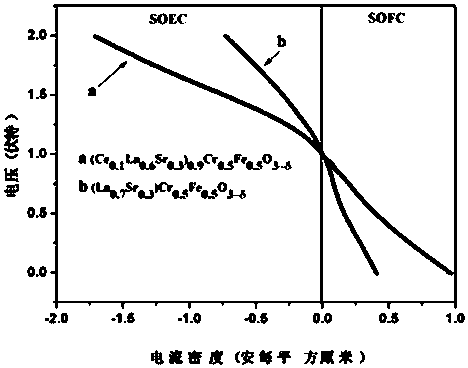

[0031] Electrochemical performance test. Put the above as (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ The high-temperature solid oxide electrolysis cell, which is an electrode, is installed on an electrochemical performance evaluation device for testing. Control the cathode atmosphere to 70% CO 2 -30%H 2 , The total flow is 26ml / min[STP], and the anode is flowing air. image 3 For (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ Polarization curve of a symmetric battery electrolyzed at 850°C. The figure shows its difference with the absence of A-site defects and Ce doping (La 0.7 Sr 0.3 )Cr 0.5 Fe 0.5 O 3-δ As a comparison of electrodes. It can be found that the A site defect-Ce atom co-doped (Ce 0.1 La 0.6 Sr 0.3 ) 0.9 Cr 0.5 Fe 0.5 O 3-δ To CO 2 The electrolysis performance is much higher than (La 0.7 Sr 0.3 )Cr 0.5 Fe 0.5 O 3-δ .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com