Double-perovskite-type anode material and preparation method thereof

An anode material, double perovskite technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of easy decomposition of materials, achieve the effects of reducing costs, improving performance, and improving catalytic activity and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

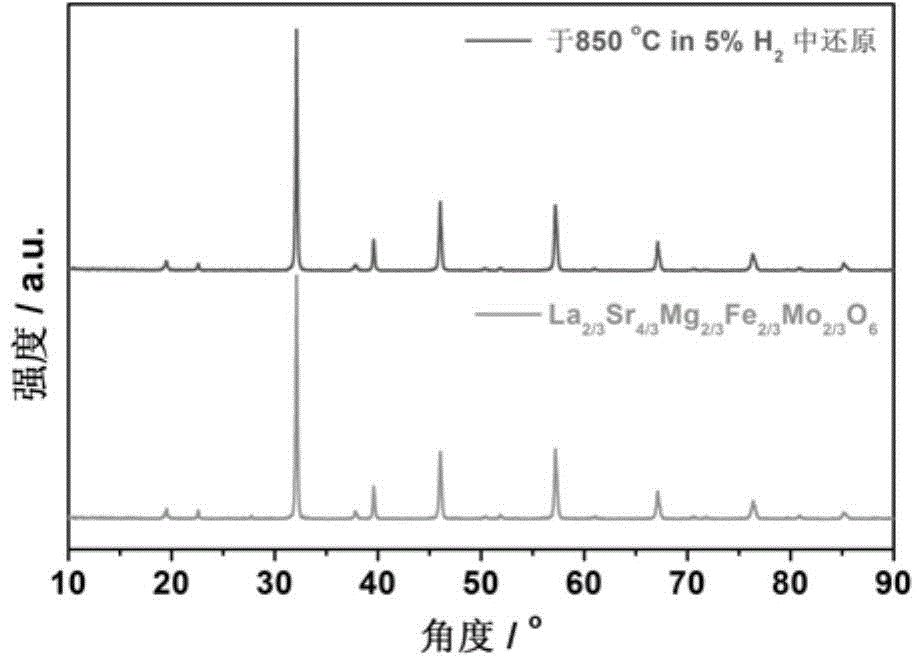

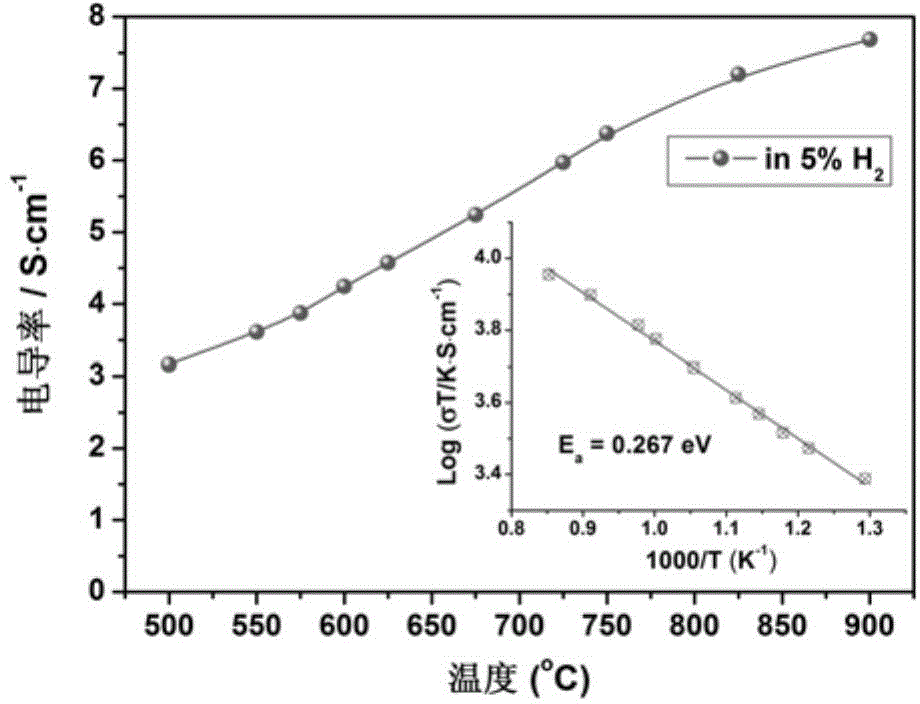

[0038] Synthesis of La by citric acid-combustion method x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) Dense sample. According to La x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) stoichiometric ratio preparation, Sr(NO 3 ) 2 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O and (NH 4 ) 6 MO 7 o 24 4H 2 O was dissolved in deionized water, and citric acid was added at a ratio of 1:2 between metal ions and citric acid, and stirred continuously to form a uniform solution. Then at 70-90 o C water bath to obtain a homogeneous sol, the sol in an oven for 80 o C to keep dry gel, then 250 o C is heated until it self-combusts to form a very fluffy La x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) precursor powder. Grind the powder and put it into an electric furnace for roasting at a temperature of 800 o C, the holding time is 6 h, so that the organic matter in it can be fully decomposed. The roasted powder was ground and sieved again, a...

Embodiment 2

[0041] Synthesis of La by citric acid-combustion method x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) anode powder. According to La x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) stoichiometric ratio preparation, Sr(NO 3 ) 2 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O and (NH 4 ) 6 MO 7 o 24 4H 2 O was dissolved in deionized water, and citric acid was added at a ratio of 1:2 between metal ions and citric acid, and stirred continuously to form a uniform solution. Then at 70-90 o C water bath to obtain a homogeneous sol, the sol in an oven for 80 o C to keep dry gel, then 250 o C is heated until it self-combusts to form a very fluffy La x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) precursor powder. Grind the powder and put it into an electric furnace for roasting at a temperature of 800 o C, the holding time is 6 h, so that the organic matter in it can be fully decomposed. The powder heat-treated in the electric furnace i...

Embodiment 3

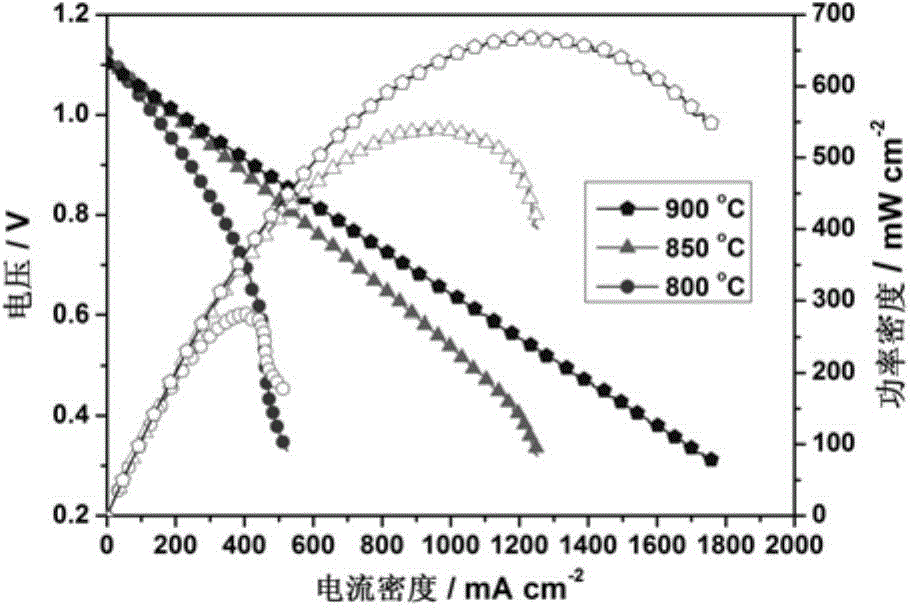

[0043] Synthesis of La by citric acid-combustion method x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) anode powder, and prepare a single battery to test battery performance. According to La x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) stoichiometric ratio preparation, Sr(NO 3 ) 2 , La 2 o 3 , Mg(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O and (NH 4 ) 6 MO 7 o 24 4H 2 O was dissolved in deionized water, and citric acid was added at a ratio of 1:2 between metal ions and citric acid, and stirred continuously to form a uniform solution. Then at 70-90 o C water bath to obtain a homogeneous sol, the sol in an oven for 80 o C to keep dry gel, then 250 o C is heated until it self-combusts to form a very fluffy La x Sr 2-x Mg 1-y Fe 2y Mo 1-y o 6-δ (x=2 / 3, y=1 / 3) precursor powder. Grind the powder and put it into an electric furnace for roasting at a temperature of 800 o C, the holding time is 6 h, so that the organic matter in it can be fully deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com