Problem-piece self-service processing system, method and self-service processing shelf

A self-service and problem-solving technology, applied in the field of logistics, can solve the problems of courier companies and staff, such as economic losses, affecting delivery speed, and information forgetting, and achieve the effects of reducing manual processing costs, improving processing efficiency, and improving service quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A self-service processing system for problematic items, the system includes an information collection module, a problematic file storage module, and a self-service processing module, wherein the information collection module, the problematic file storage module, and the self-service processing module are connected to each other;

[0046] The problem file storage module is used to store the problem file;

[0047] The information collection module collects problem information in real time and uploads it to the self-service processing module;

[0048] The self-service processing module sends a problem file processing command to the responsible associated end of the current processing stage of the problem file according to the problem file information, and sends the delivery, pick-up and problem handling of the problem file to the relevant responsible associated end according to the processing result of the current responsibility associated end of the problem file Process c...

Embodiment 2

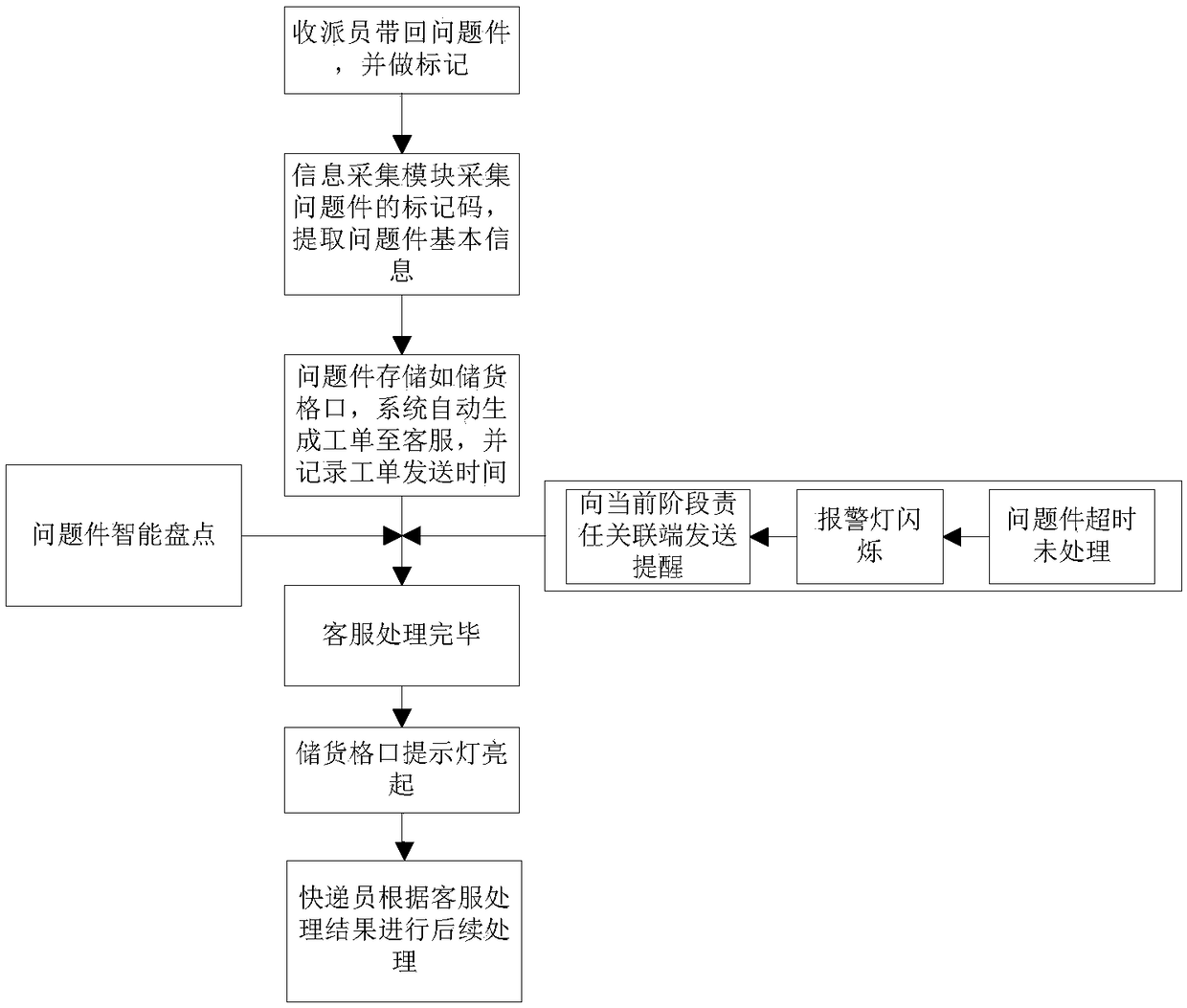

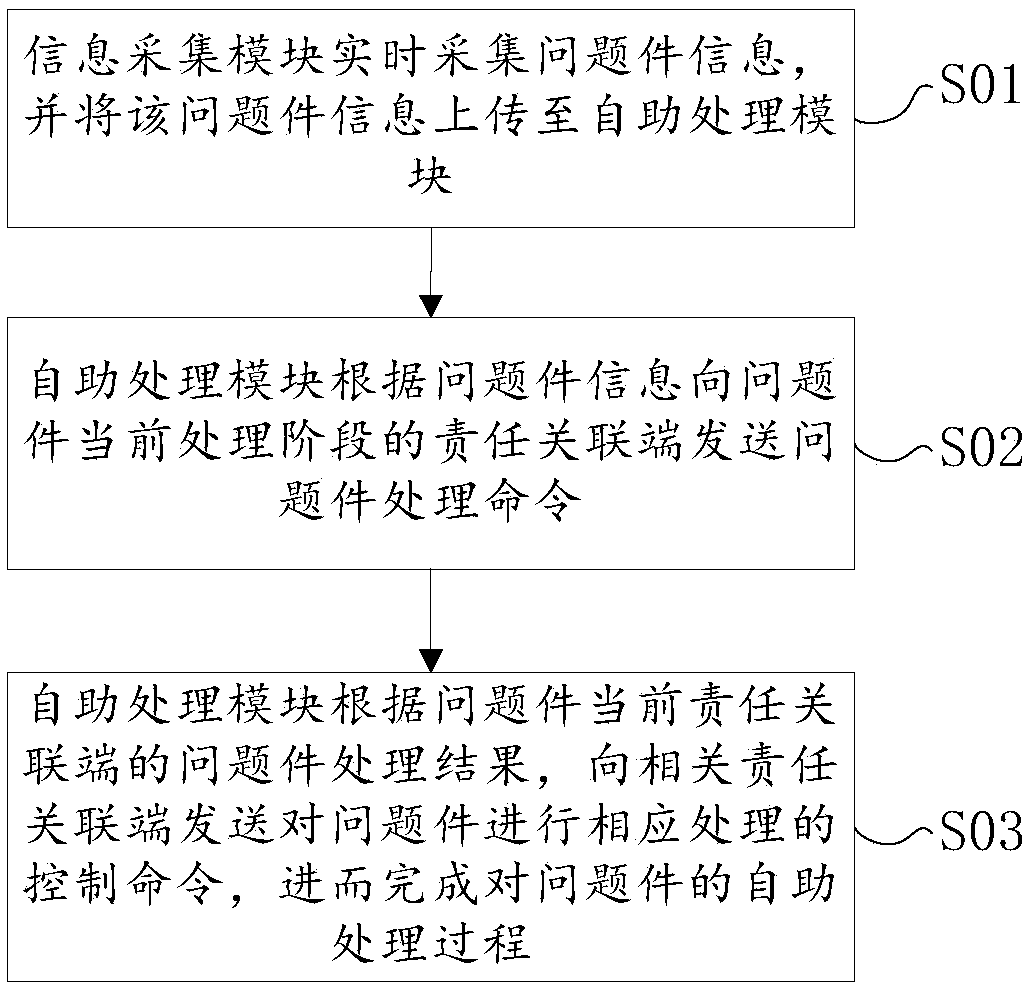

[0066] This embodiment provides a self-service processing method for problem files, such as figure 2 As shown, the following takes a complete problem handling process as an example to describe the method in detail:

[0067] S01: The information collection module collects problem piece information in real time, and uploads the problem piece information to the self-service processing module.

[0068] Collect problem piece information, the information collection module scans the problem piece information to be stored, and uploads it to the self-service processing module, and the self-service processing module controls and opens the problem piece storage module according to the problem piece information to store the problem piece;

[0069] in:

[0070] The specific collection process of the information collection module is: the information collection module collects the identification codes of the problem pieces whose problem information has been entered by the receiving and dis...

Embodiment 3

[0081] This embodiment provides a self-service processing shelf, which includes: a shelf body, an information collection device and a central processing unit arranged on the shelf body, specifically:

[0082] Information collection device: including a problem part identification code scanning gun or a scanning window for real-time collection of problem part information;

[0083] The shelf body includes a plurality of storage grids for storing problem pieces, and the information collection device is located at the front end of the shelf body. Of course, the function of the information collection device is to collect information on the identification code of the problem piece, so the present invention places its location , The connection method with the shelf body is not limited;

[0084] The central controller receives the problematic piece information collected by the information collection module in real time, automatically generates a work order to the customer service accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com