Components and methods for milk frothing

A component and heating unit technology, which is applied in the field of components that make milk foam, can solve the problems of valve components that are susceptible to contamination, bacterial growth, complex structure, etc., and achieve the effects of reduced complexity, high energy efficiency, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

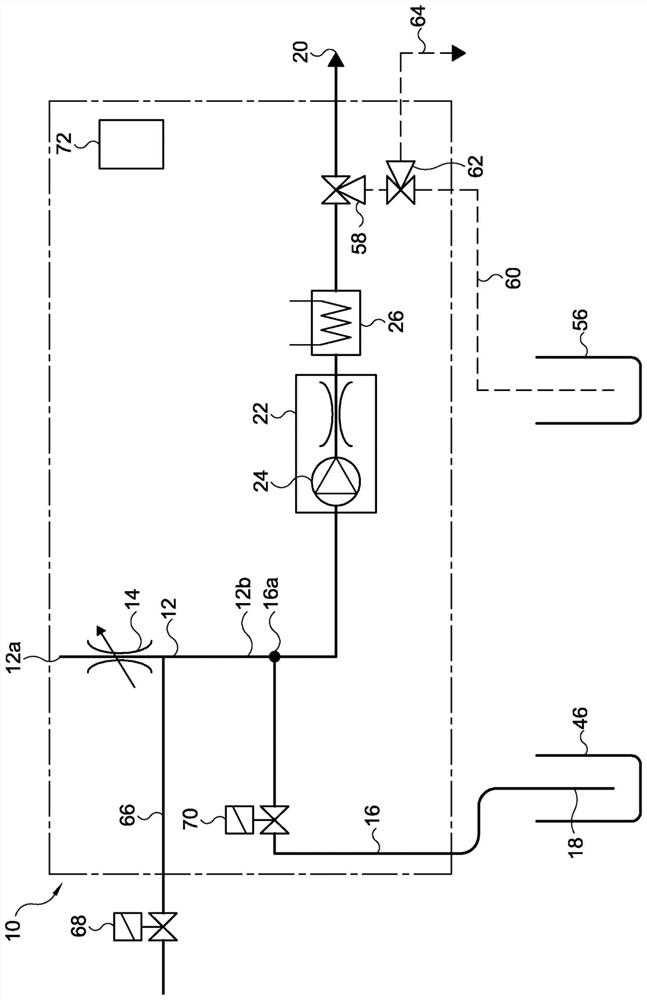

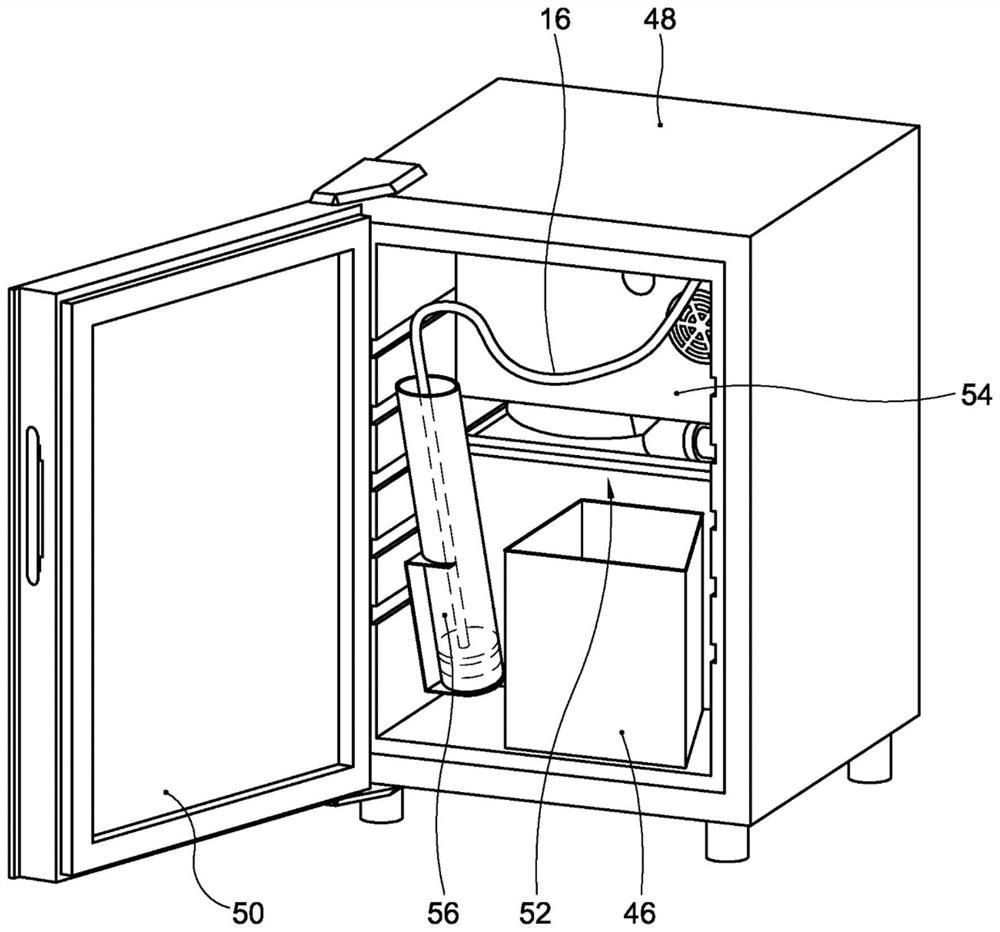

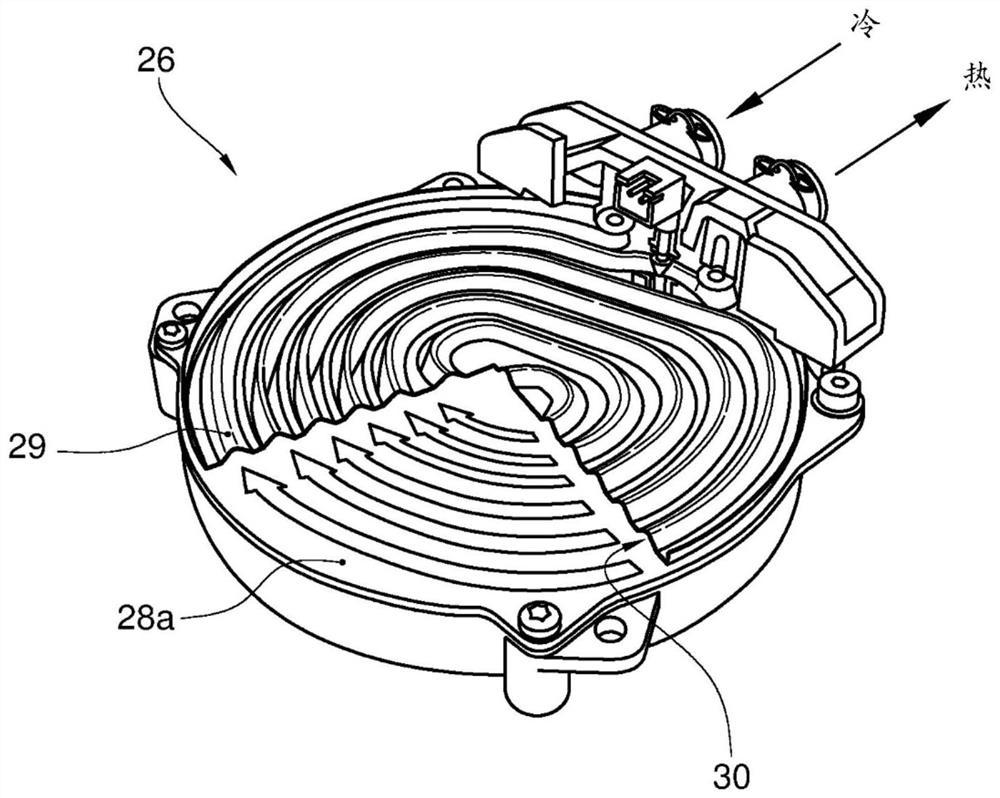

[0047] In most general terms, the assembly 10 for frothing milk comprises an air supply assembly comprising an air source and an air channel 12 having an air inlet 12a and a downstream end 12b. An air source is connected to the air inlet 12a. In one embodiment, the air supply assembly can be configured to control the flow of air supplied to the downstream end. This can be achieved by an air pump connected to the air inlet 12 a and capable of producing a variable flow or by a controllable air valve 14 installable in the air channel 12 . Assembly 10 also includes a fluid channel 16 extending from fluid inlet 18 to fluid outlet 20 . The fluid channel 16 then comprises: an air inlet exit point 16a connecting the downstream end of the air channel 12b, a bubbling unit 22 comprising a pump 24 and a flow-through heating unit 26 defining a heating unit of a portion of the fluid channel 16 Fluid channel 30 . The flow-through heating unit 26 has an energized state and a non-energized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com