Apparatus and method for automatically converting thermal displacement compensation parameters of machine tool

A technology of compensating parameters and automatic conversion, applied in automatic control devices, feeding devices, computer control, etc., can solve the problems of decreased production efficiency, neglect, and decreased processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0058] Unless there is a special definition, all terms in this specification have the same common meanings as understood by those skilled in the art. When a term used in this specification conflicts with the usual meaning of the term, follow the Definition.

[0059] It should be noted that the inventions to be described below are only used to illustrate the embodiments of the present invention and are not intended to limit the scope of rights of the present invention. The same reference numerals used throughout the specification represent the same constituent elements.

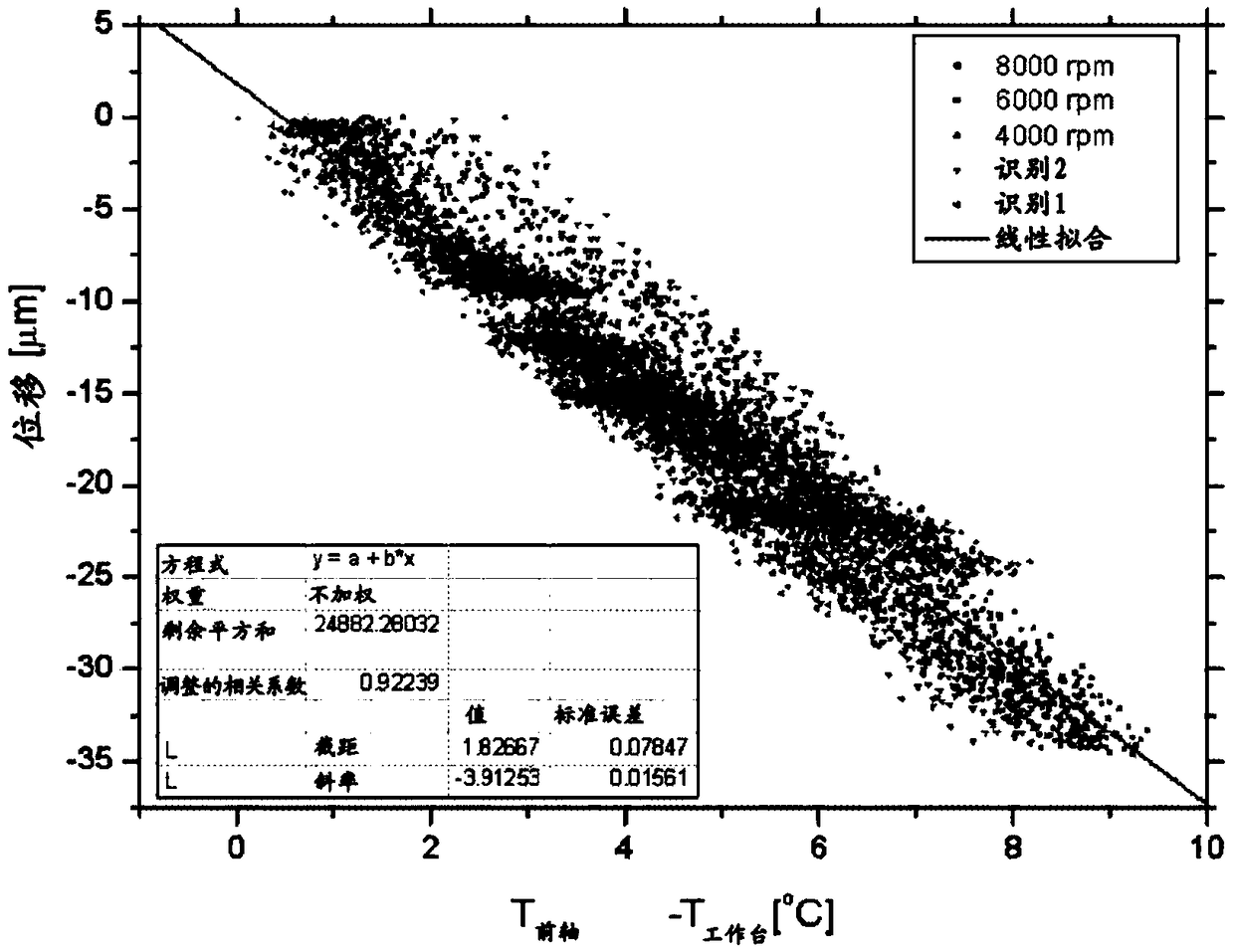

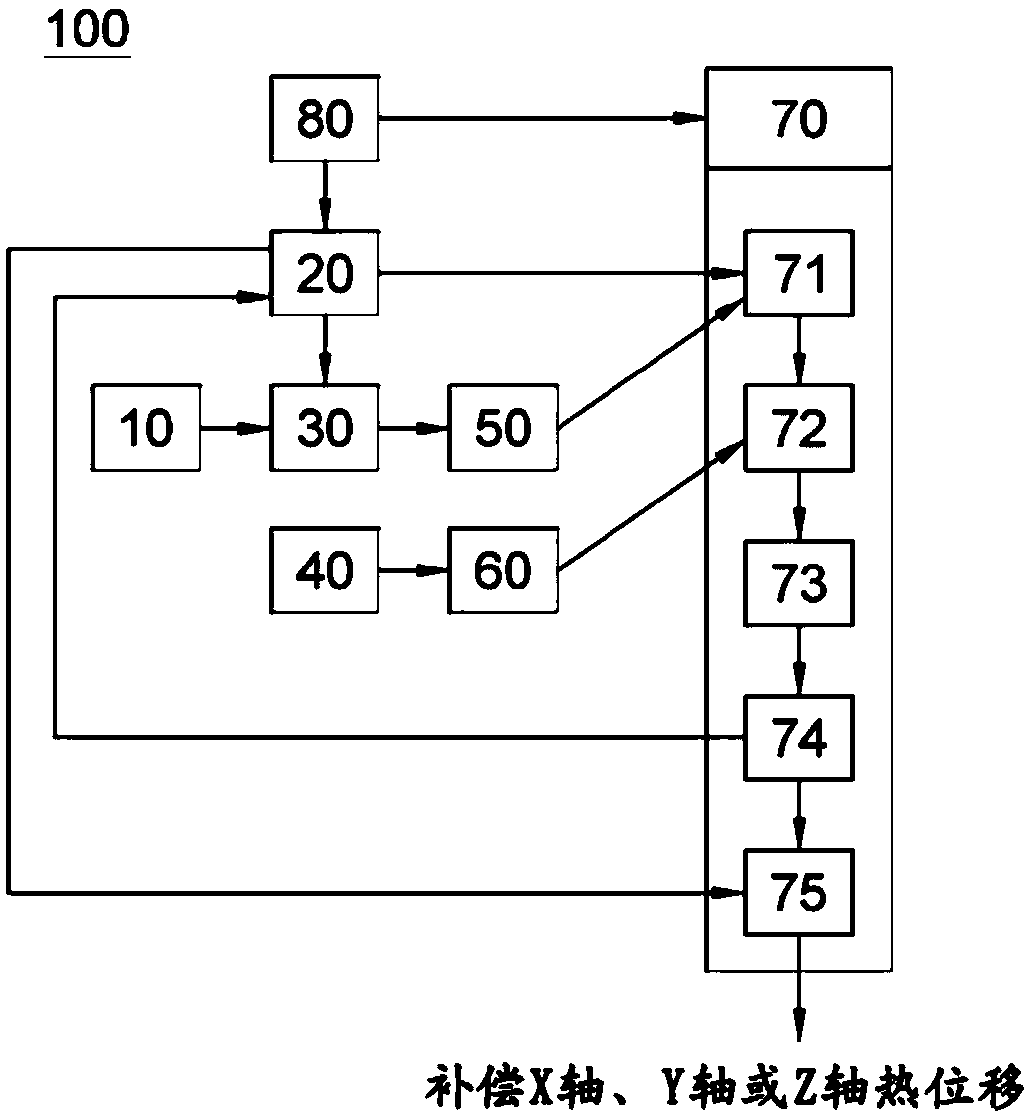

[0060] image 3 It is a block diagram of the thermal displacement compensation parameter automatic conversion device of the machine tool of the embodiment of the present invention, Figure 4 It is a diagram illustrating a screen of an operation panel for calculating compensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com