Method for robot-assisted production of a support structure for a passenger transport system

A load-bearing structure and transportation system technology, applied in transportation and packaging, manipulators, manufacturing tools, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

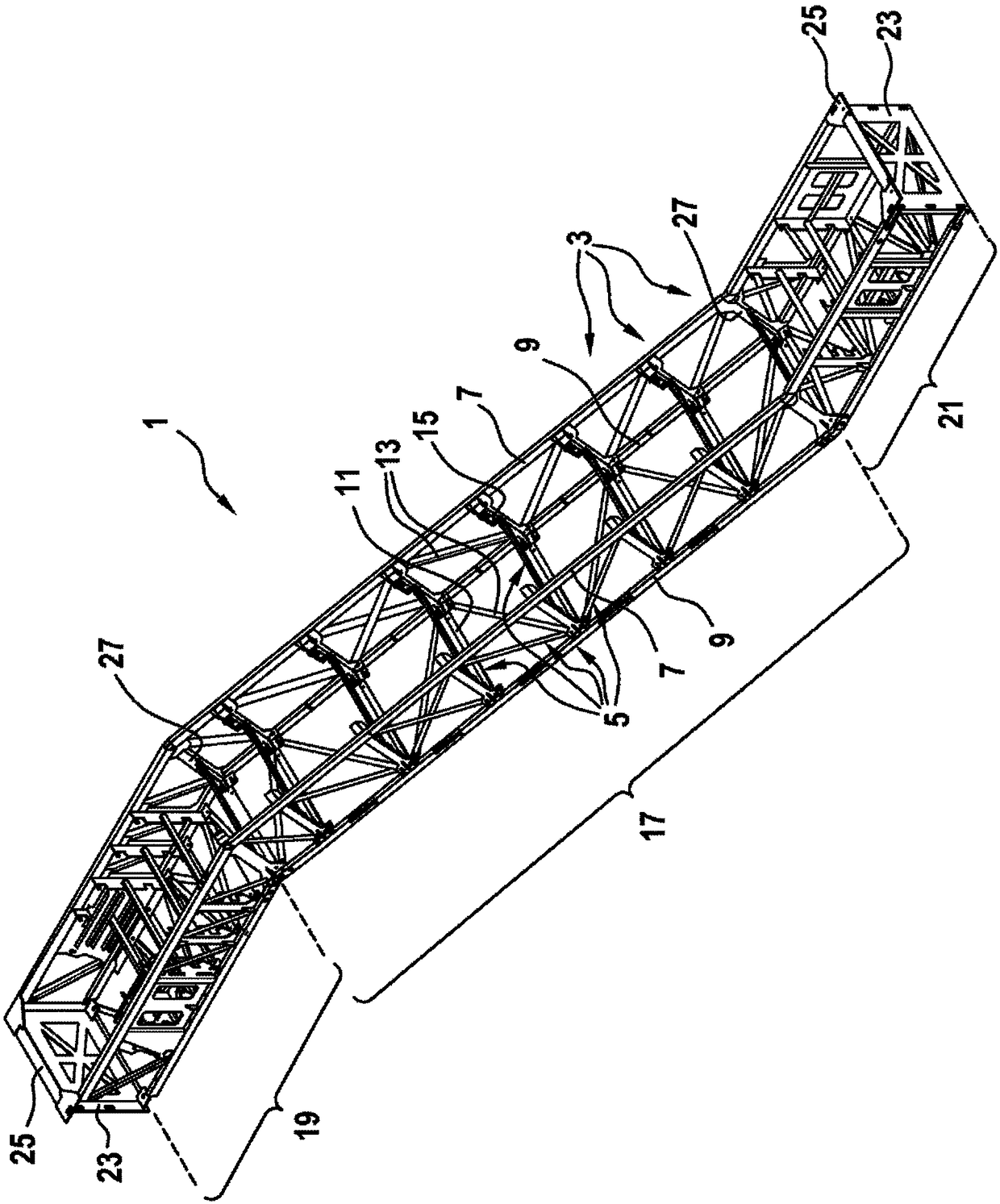

[0047] figure 1 An example of a load-bearing structure 1 for a passenger transport system is shown. In the example shown, the load-bearing structure 1 is designed as a frame structure 3, which can form the load-bearing structure of an escalator by means of which people can be transported, for example, between two floors of a building. Shipping between.

[0048] The frame structure 3 of the load-bearing structure 1 consists of a plurality of interconnected frame structure parts 5 . Here, some frame structure parts 5 form an upper chord 7 and a lower chord 9 extending parallel to each other and parallel to the direction of extension of the elongated load-bearing structure 1 . The other frame structural parts 5 form cross braces 11 , diagonal braces 13 and uprights 15 extending transversely to and connecting the upper and lower chords 7 , 9 .

[0049] At the middle part 17 of the support structure 1 , which runs obliquely in the state installed in the building, a horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com