Electric drill positioning vacuum cleaner

A technology for vacuum cleaners and electric drills, applied in portable drilling rigs, drilling/drilling equipment, portable motorized devices, etc., can solve problems such as air pollution, inconvenient cleaning, and affecting normal breathing of construction workers, and achieve accurate drilling results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

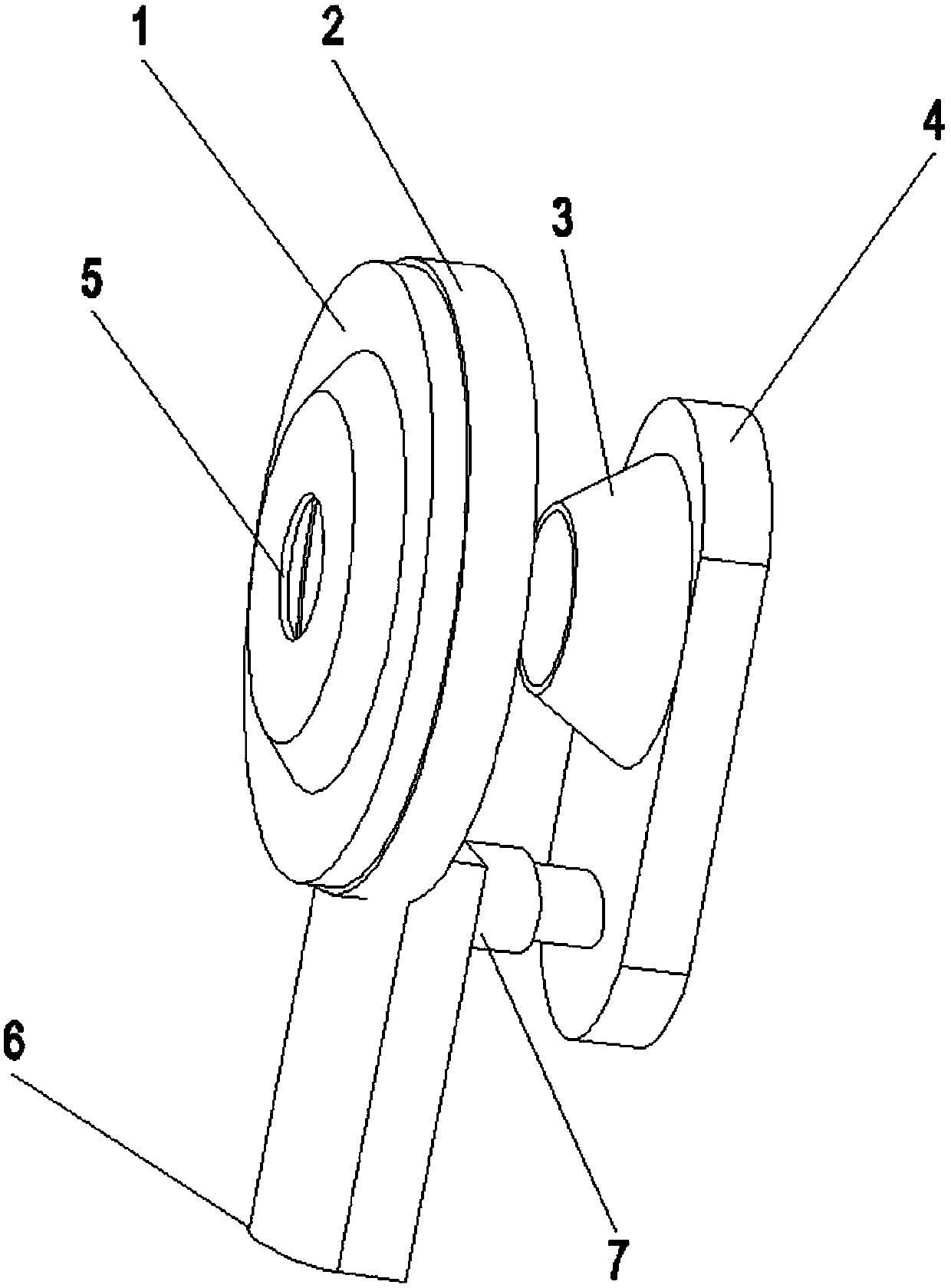

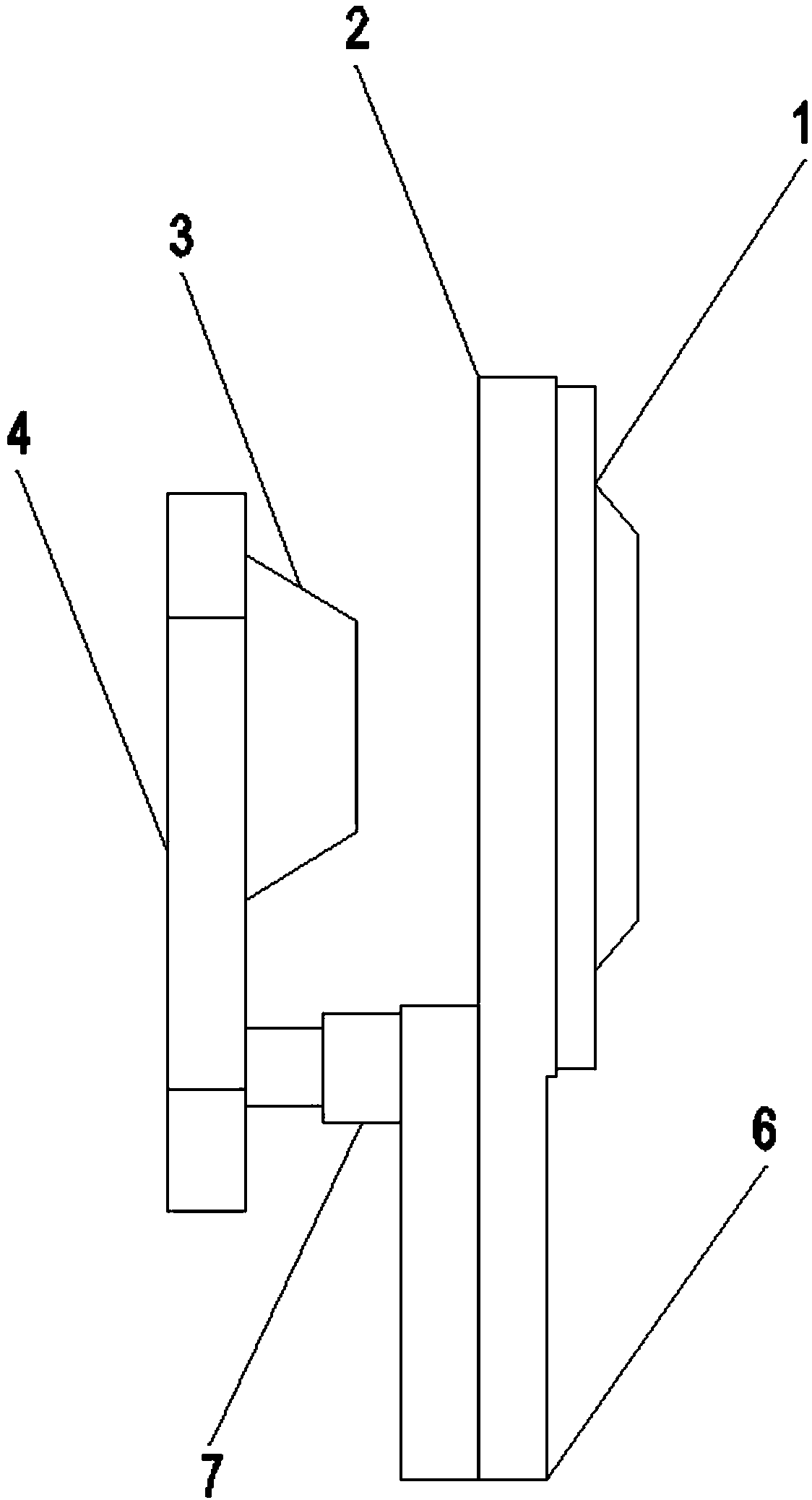

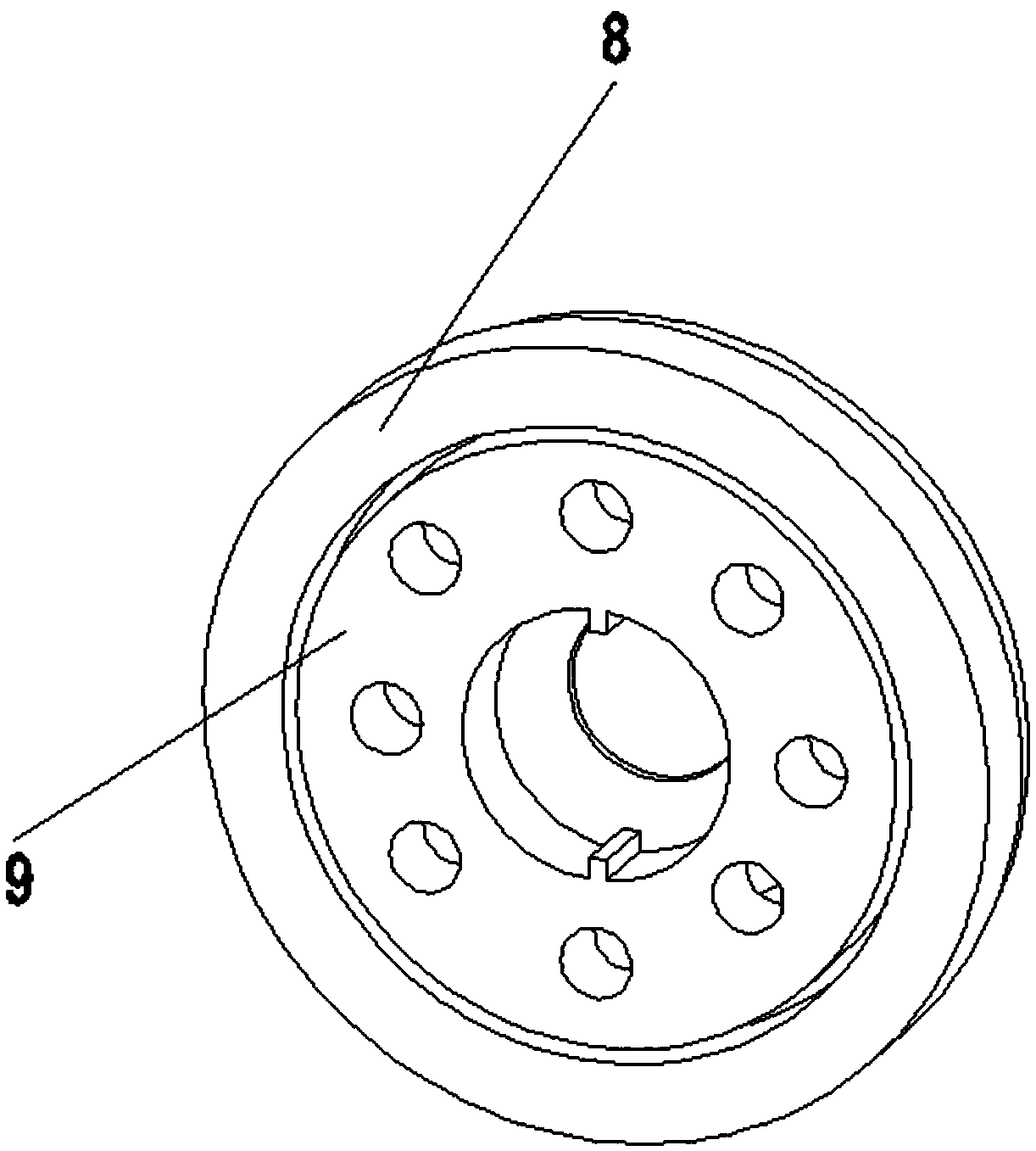

[0022] see Figure 1~7 As shown, it is a structural schematic diagram of a preferred embodiment of the present invention. An electric drill positioning vacuum cleaner mainly includes: a positioning plate 4, a vacuum cleaner 2, a handle 6 and a telescopic rod 7, and the upper end of the positioning plate 4 is provided with a positioning hole Ⅰ10, the lower end of the positioning plate 4 is provided with a small pin hole 11, the handle 6 is provided with a vacuum cleaner 2, the side of the handle 6 is provided with a large pin hole 15, and the telescopic rod 7 is respectively inserted into the small pin hole 11 and the large pin hole 15 to connect the positioning plate 4 and The handle 6, the vacuum cleaner 2 includes an inner core 9, a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com