Steel pipe end face polishing machine

A steel pipe and grinding machine technology, which is applied in the direction of grinding racks, grinding machine parts, grinding machines, etc., can solve the problems of high labor intensity for operators, unfavorable subsequent application of steel pipes, and low grinding precision of steel pipes, and achieve flexible setting positions , convenient positioning, and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

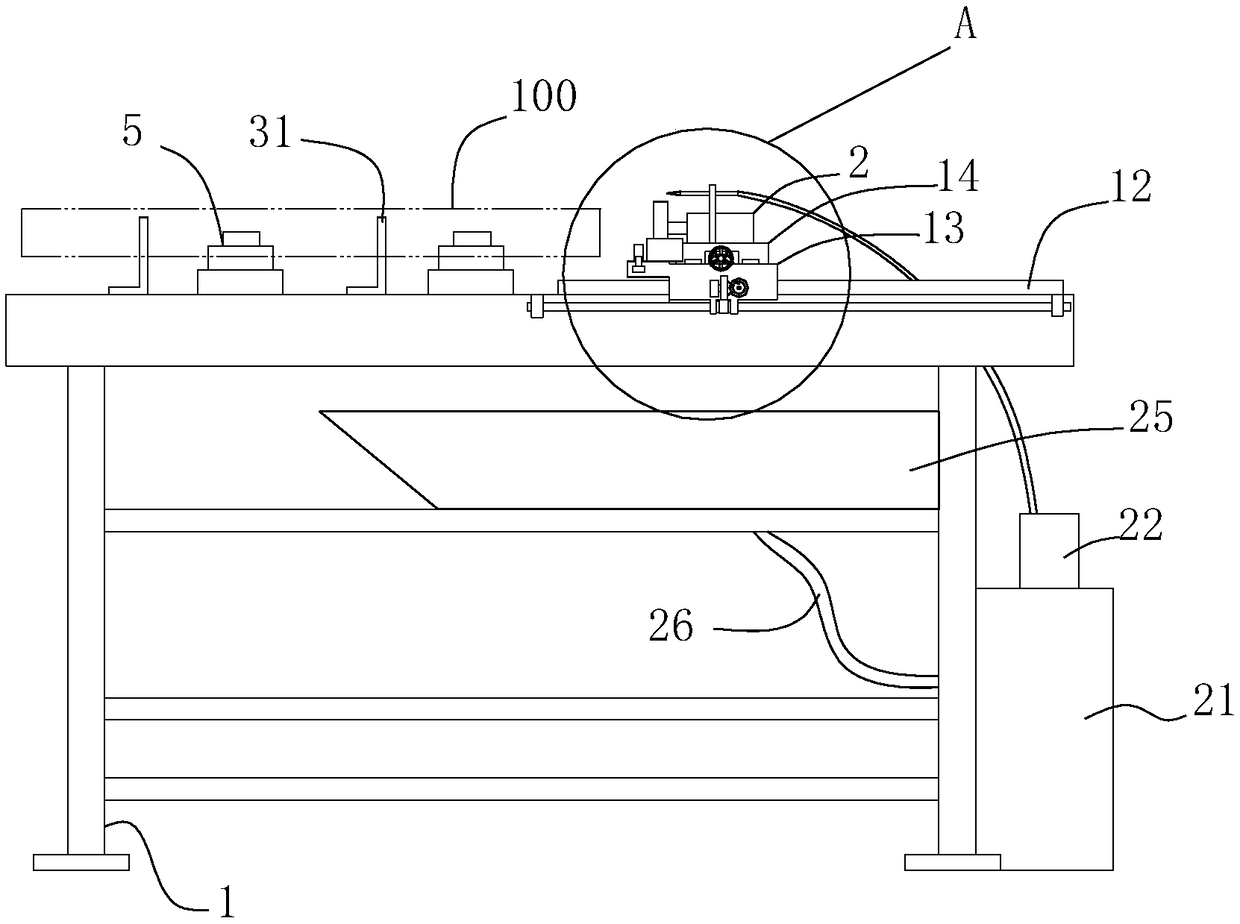

[0030] The steel pipe end face grinder is used for grinding the end face of the steel pipe 100 to facilitate the subsequent use of the steel pipe 100 .

[0031] like figure 1 , The steel pipe end face grinding machine includes a frame 1, which can be formed by splicing rods, and the rods can be spliced by bolts or welded to form the frame 1.

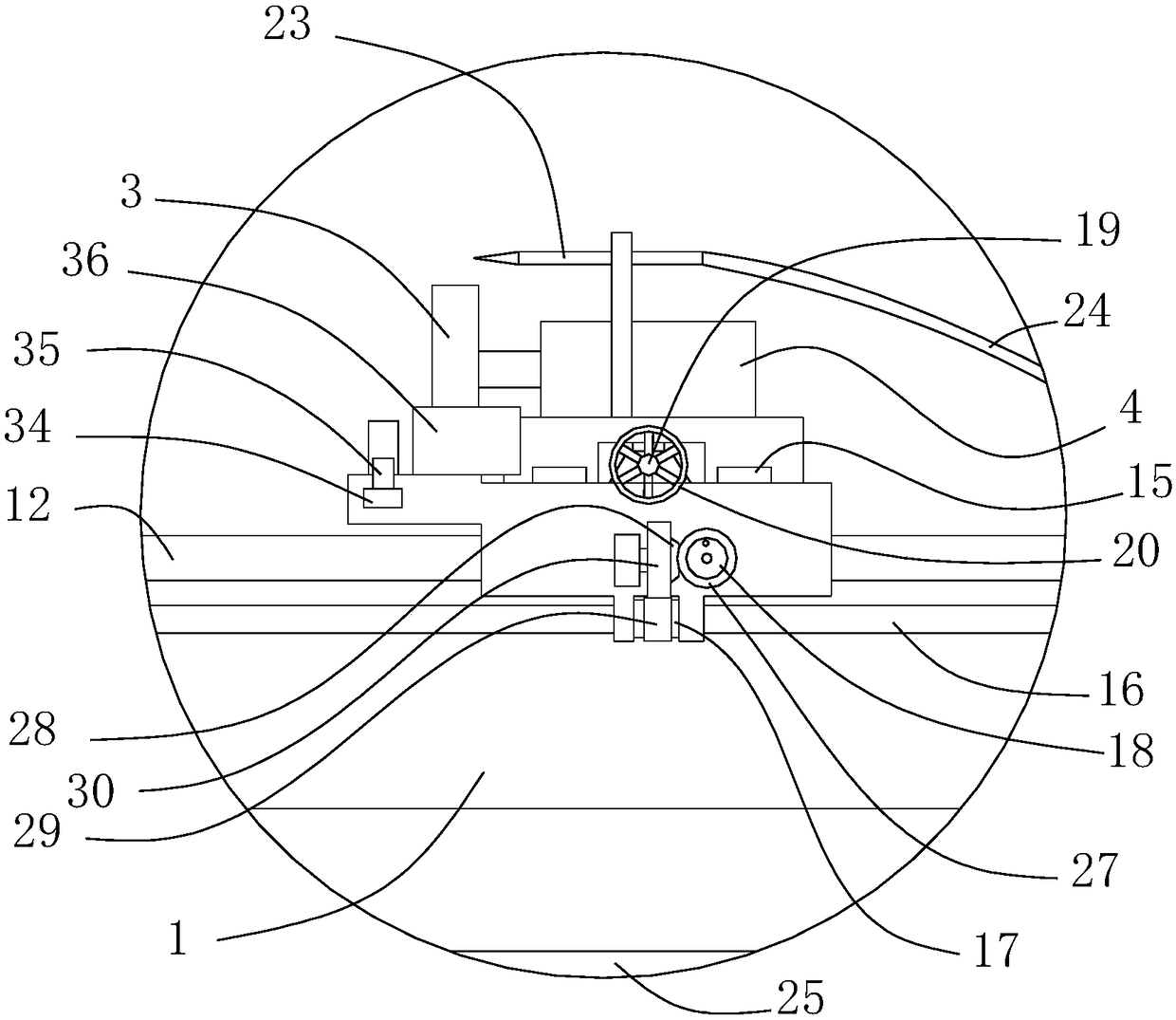

[0032] like figure 1 , figure 2 , the frame 1 is provided with a grinder 2, the grinder 2 includes a grinding head 3 and a driving motor 4 that drives the rotation of the grinding head 3, and the driving motor 4 is fixed on the frame 1, The driving motor 4 includes an output shaft, and the grinding head 3 is fixed on the output shaft of the driving motor 4 through threads. .

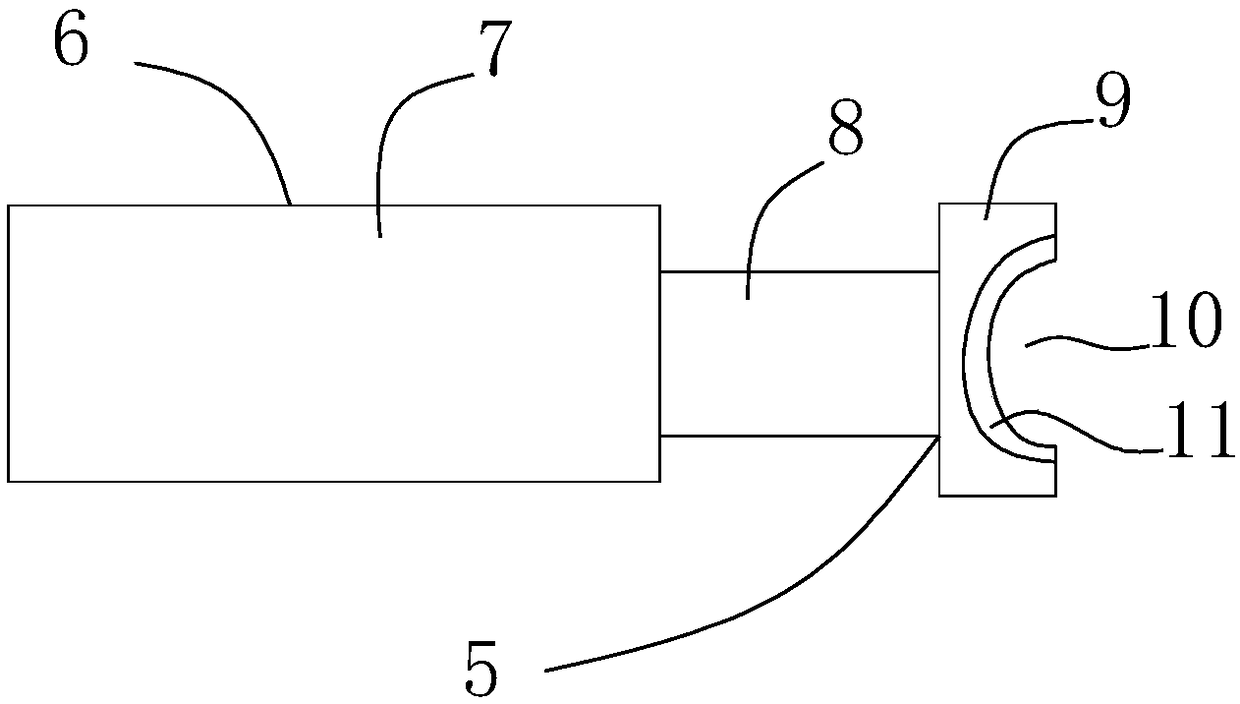

[0033] like figure 1 , figure 2 , image 3 , the frame 1 is also provided with a clamper 5 for clamping the steel pipe 100 , there are multiple clampers 5 , and the clampers 5 are respectively located on both sides of the steel pipe 100 to clamp the stee...

Embodiment 2

[0042] This embodiment is an optimization scheme for embodiment 1 in combination with embodiment 1.

[0043] like figure 1 , figure 2 , the steel pipe end face grinding machine also includes a cutting fluid supplier, the cutting fluid supplier includes a water tank 21, the water tank 21 is used to accommodate the cutting fluid, the water tank 21 can be fixed with the frame 1, or the water tank 21 can not be fixed with the frame 1 , the installation position of the water tank 21 is not specifically limited.

[0044] A water pump 22 is arranged in the water tank 21 , and a nozzle 23 is arranged on the sliding frame 14 , and the water pump 22 supplies liquid to the nozzle 23 through a hose 24 .

[0045] The cutting fluid supplier also includes a water collecting box 25 for collecting the cutting fluid ejected from the nozzle 23. The water collecting box 25 communicates with the water tank 21 through a pipeline 26. The water collecting box 25 is mainly used for collecting the c...

Embodiment 3

[0048] This implementation introduces the structure of the gear transmission mechanism in combination with Embodiment 1 or Embodiment 2.

[0049] like figure 1 , figure 2 , the handle 18 is rotatably connected to the sliding seat 13, the gear transmission mechanism includes a driving bevel gear 27 which rotates synchronously with the handle 18 and a driving bevel gear 27 which is rotatably connected to the sliding seat 13 and the driving bevel gear 27 Engaged driven bevel gear 28. The setting of the driving bevel gear 27 and the driven bevel gear 28 is mainly used to change the direction of power transmission, so that the setting position of the handle 18 is flexible, and the operability of the handle 18 is optimized.

[0050] The nut 17 is provided with a first tooth portion 29, the nut 17 and the first tooth portion 29 are integrally structured, and the driven bevel gear 28 is provided with a second tooth meshing with the first tooth portion 29. The part 30, the driven b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com