Front suspension control arm

A technology of control arm and front suspension, applied in suspension, cantilever mounted on pivot, transportation and packaging, etc., can solve the problems of difficulty in eliminating the cause of casting defects, high development cost, low production efficiency, etc. The effect of improving processing efficiency and yield, reducing production cost and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

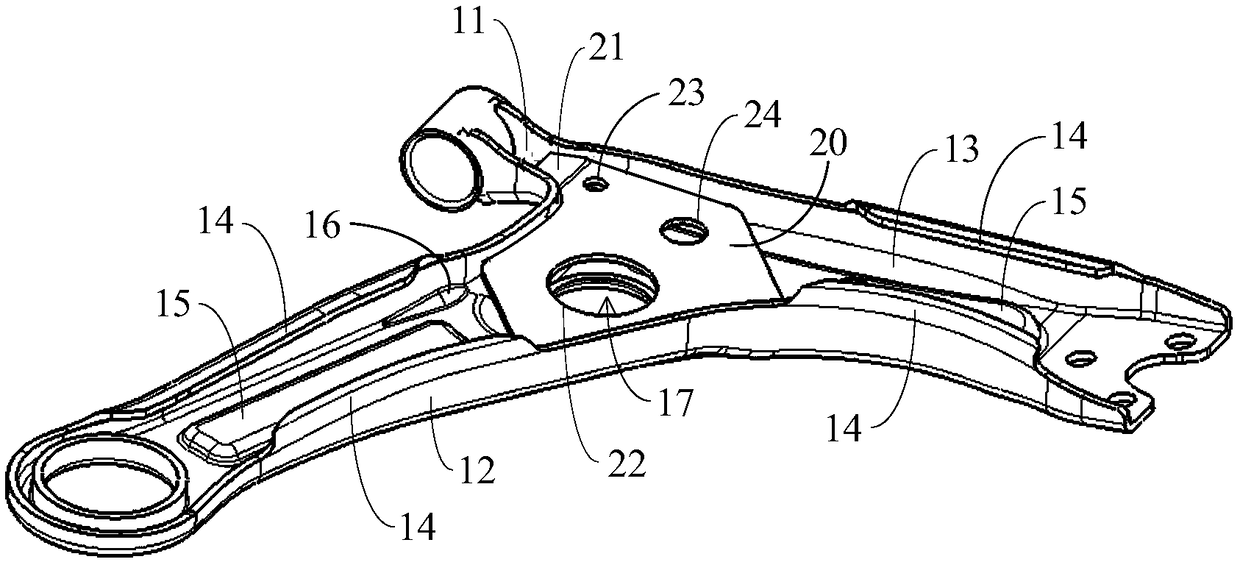

[0013] The specific implementation manner of the present invention will be further described in detail below by describing the embodiments in conjunction with the accompanying drawings.

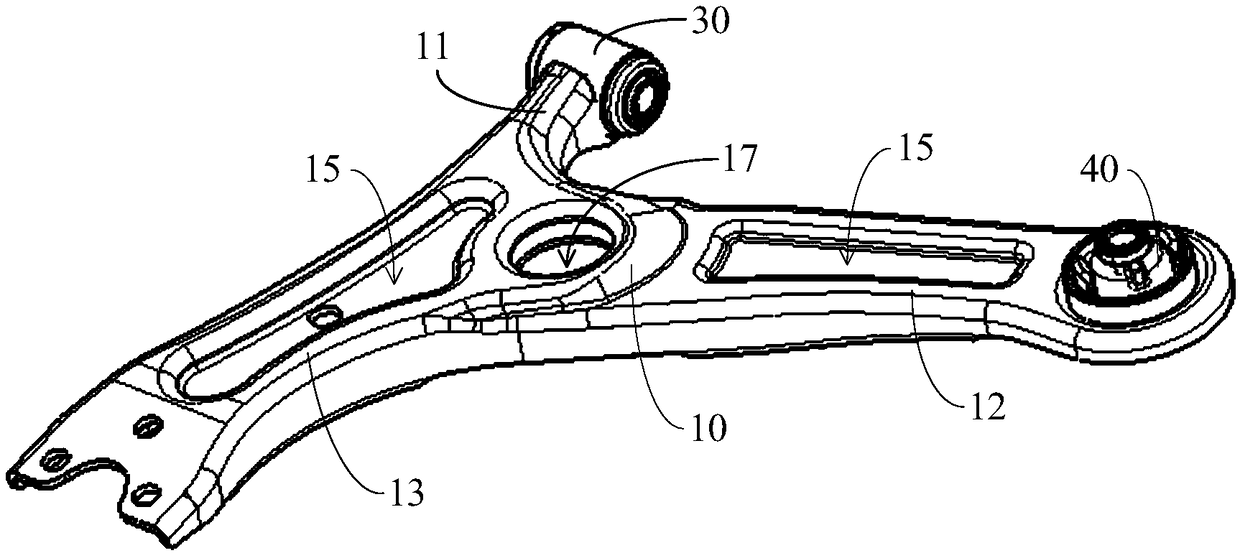

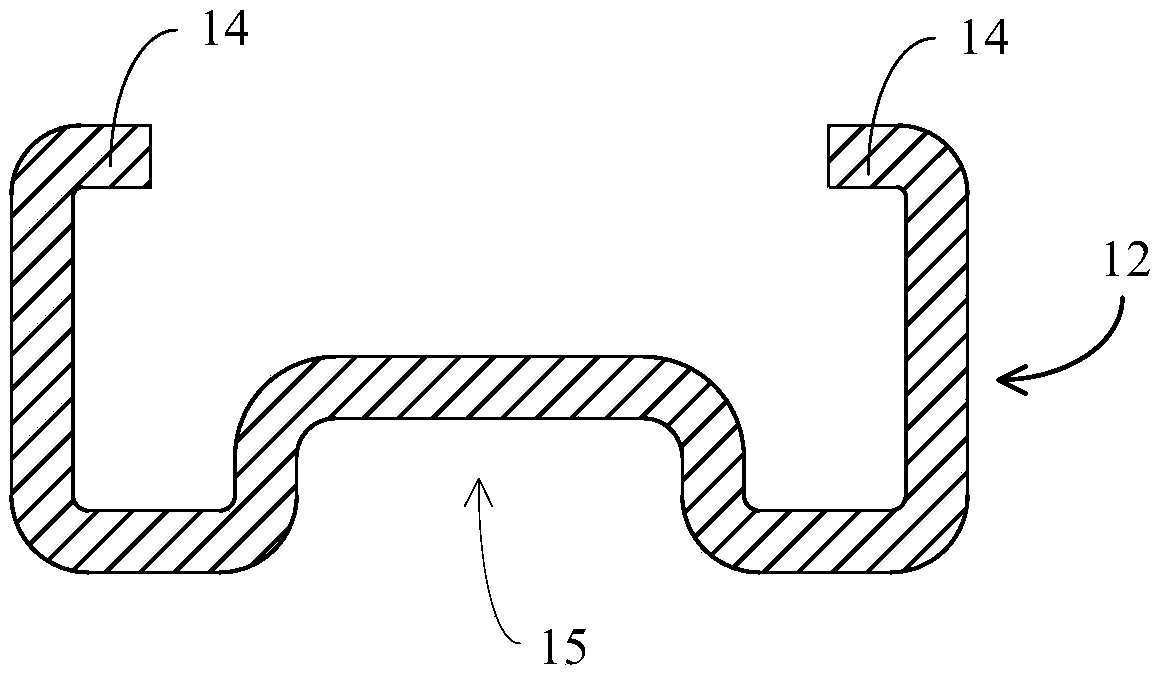

[0014] A front suspension control arm, comprising a control arm body 10 integrally stamped and formed, the control arm body 10 extends to the inside of the vehicle body with first and second connecting arms 11 and 12 connected to the sub-frame, the first and second connecting arms 11 The cantilever ends of , 12 are arranged along the front and rear direction of the vehicle body, and the control arm body 10 extends to the outside of the vehicle body with a third connecting arm 13 connected to the steering knuckle, where the arm bodies of the first, second and third connecting arms 11, 12, 13 gather A reinforcing plate 20 is provided. The integrated stamped control arm body 10 combined with the reinforcing plate 20 arranged at the gathering place of the arm body not only facilitates processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com