Denitrification biofilter reactor utilizing corncob as bio-carrier and method for treating sewage by denitrification biofilter reactor

A denitrification filter and reactor technology, applied in chemical instruments and methods, biological water/sewage treatment, anaerobic digestion treatment, etc., can solve the problem of expensive carbon sources, effluent TN that cannot meet the national first-class A standard, and treatment High cost and other problems, to achieve the effect of reducing costs, ensuring long-term stable operation, and increasing removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

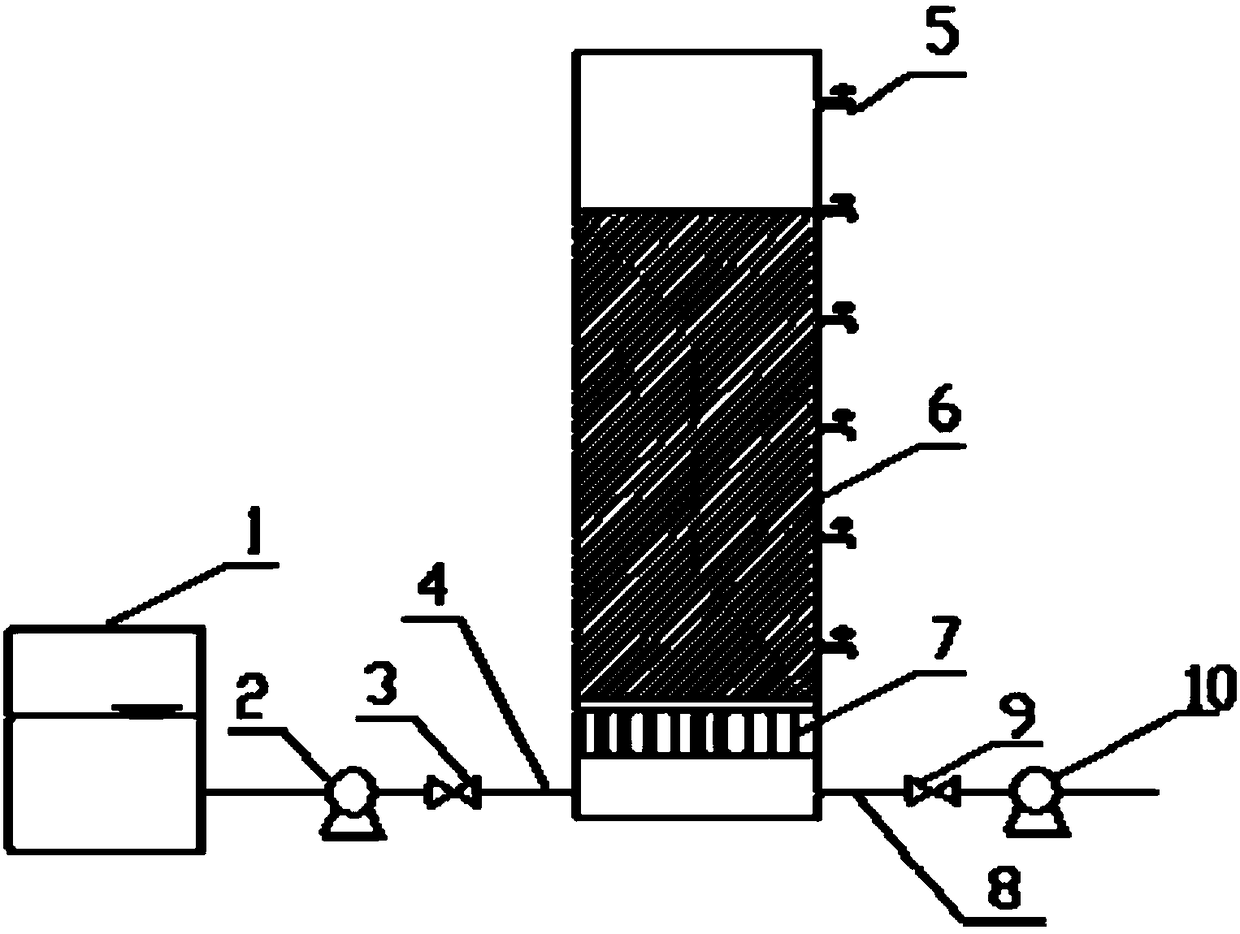

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, a denitrification filter reactor using corncob as a biomass carrier in this embodiment includes a reactor main body, an inlet water tank 1, an inlet pipe 4, a plurality of outlet pipes 5 and a backwash inlet pipe 8;

[0022] The reactor main body includes a biomass carrier 6 and a supporting plate 7, and the biomass carrier 6 and the supporting plate 7 are arranged inside the reactor main body from top to bottom;

[0023] Below the supporting plate 7, a water inlet and a backwash water inlet are opened on the side wall of the reactor main body; above the supporting plate 7, a plurality of water outlets are opened from top to bottom on the side wall of the reactor main body; The water pipe 5 communicates with the reactor main body through the water outlet;

[0024] The water inlet tank 1 communicates with the reactor main body through the water inlet pipe 4 and the water inlet; the backwash wat...

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the main body of the reactor is closed. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: the support plate 7 is evenly provided with a plurality of holes with a diameter of 0.6 mm to 0.8 mm, and the perforations of the support plate 7 The rate is 10% to 15%. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com