An X-ray dynamic image system of explosive foil flyers

A technology of dynamic imaging and explosive foil, which is applied in the field of high-speed X-ray imaging, can solve the problems of expensive and complex implementation, and achieve the effect of simple implementation and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

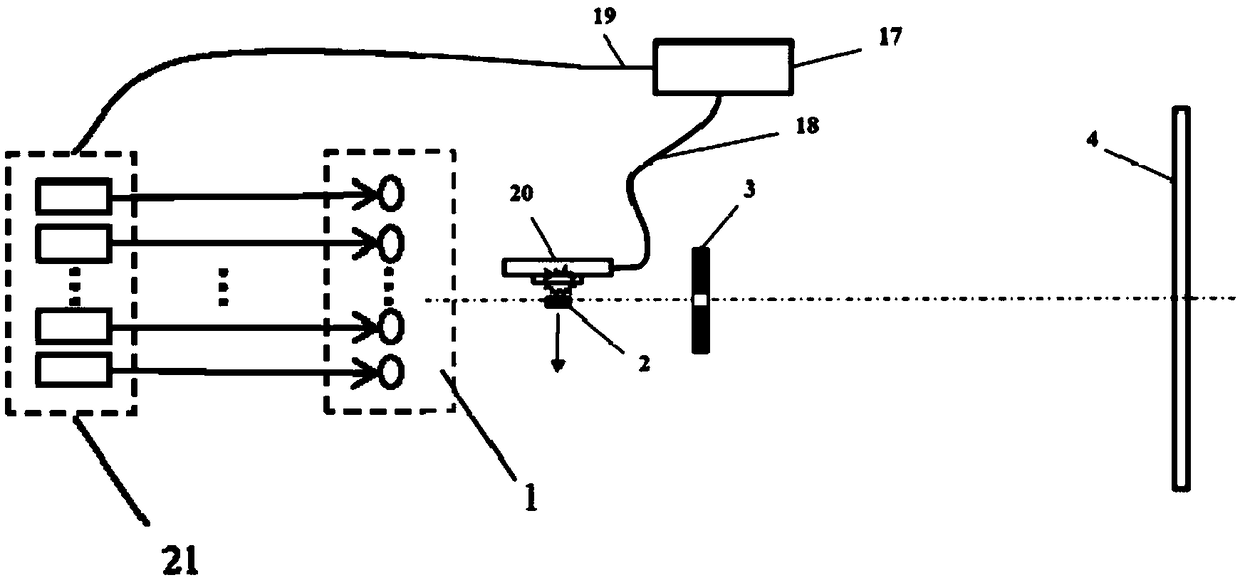

[0027] see figure 1 , which is a schematic structural diagram of an explosive foil flyer X-ray dynamic imaging system provided in an embodiment of the present application. An explosive foil flyer X-ray dynamic imaging system includes a signal synchronization device 20 , a pulsed laser array 21 , a metal target array 1 , a small-hole imaging plate 3 and a recording medium 4 .

[0028] The signal synchronization device 20 is used for outputting electrical pulse sequences.

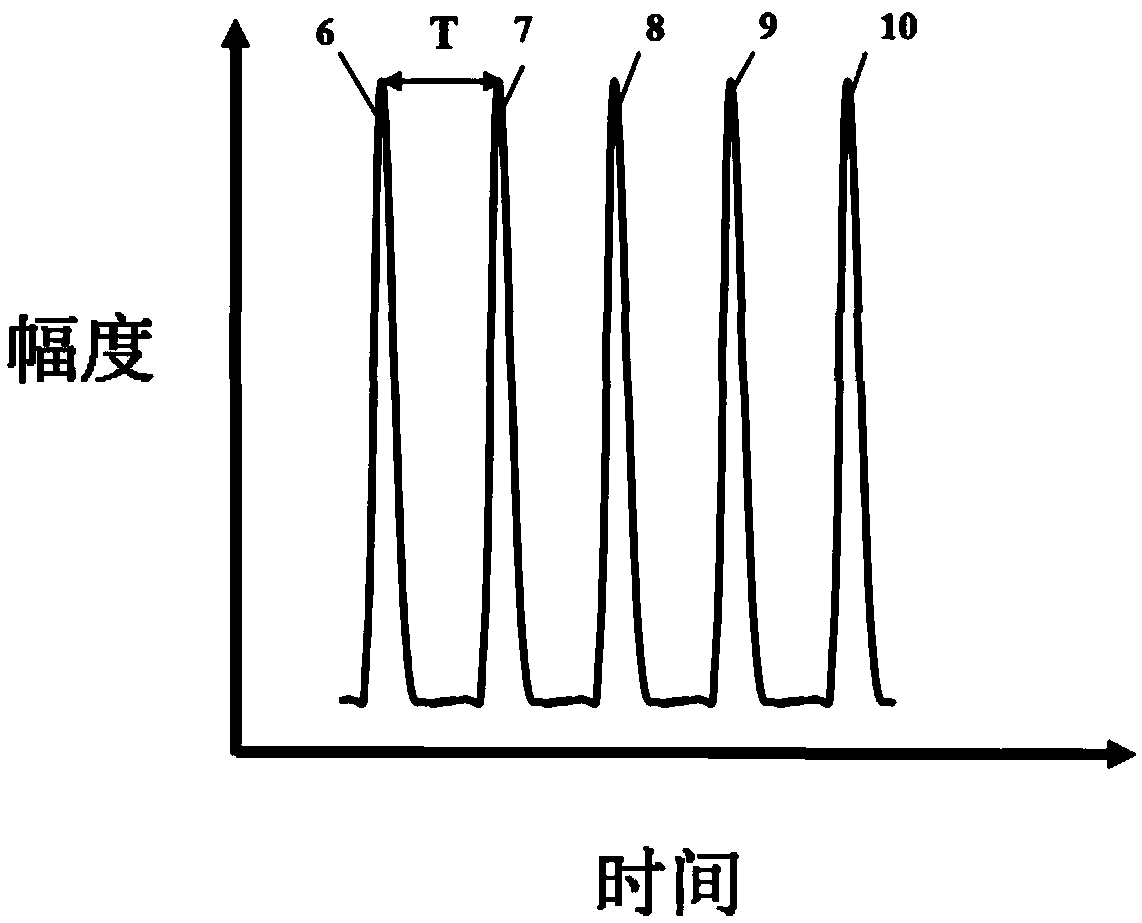

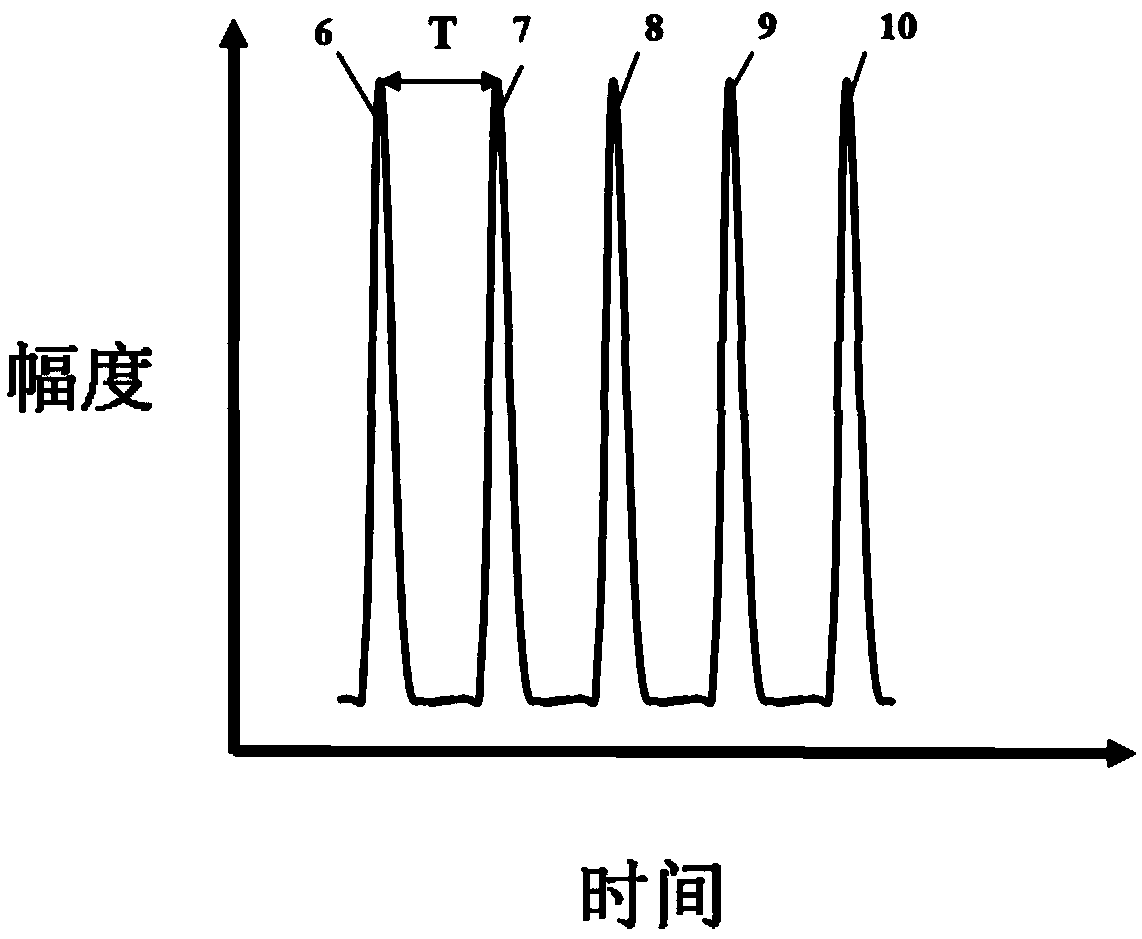

[0029] It should be noted that the number of electric pulses in the electric pulse sequence can be adjusted according to actual needs, and the number of electric pulses determines the number of dynamic images of the explosive foil flyer that can be obtained. The time interval of the electrical pulse sequence can be the same, that is, a periodic sequence of pulses, or the time interval can be different, which is a sequence of pulses with variable period.

[0030] Each laser of the pulsed laser array 21 is us...

Embodiment 2

[0042] Hereinafter, based on the above embodiments, taking the electric pulse sequence including 5 electric pulses as an example, an explosive foil flyer X-ray dynamic imaging system of this embodiment will be described in detail.

[0043] see figure 2 , which is another structural schematic diagram of an explosive foil flyer X-ray dynamic imaging system provided in this embodiment. The metal target array includes a first metal target 11, a second metal target 12, a third metal target 13, a fourth metal target 14 and a fifth metal target 15, and each metal target is arranged at equal intervals, while in the metal target array The target surface normal of each metal target is perpendicular to the small hole imaging plate. The metal target is mounted on the base 5 through a metal rod 16 .

[0044] The metal target array 1 , the pinhole imaging plate 3 , the explosive foil device 20 to be tested and the recording medium 4 are aligned with each other.

[0045] The explosive fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com