A method for improving the performance of molybdenum disulfide catalytic hydrogen evolution

A technology of molybdenum disulfide and hydrogen evolution, which is applied in the field of catalytic hydrogen evolution, can solve the problems of unsatisfactory performance and performance impact of molybdenum disulfide catalytic hydrogen evolution, and achieve the effect of improving catalytic hydrogen evolution performance and consistent excellence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

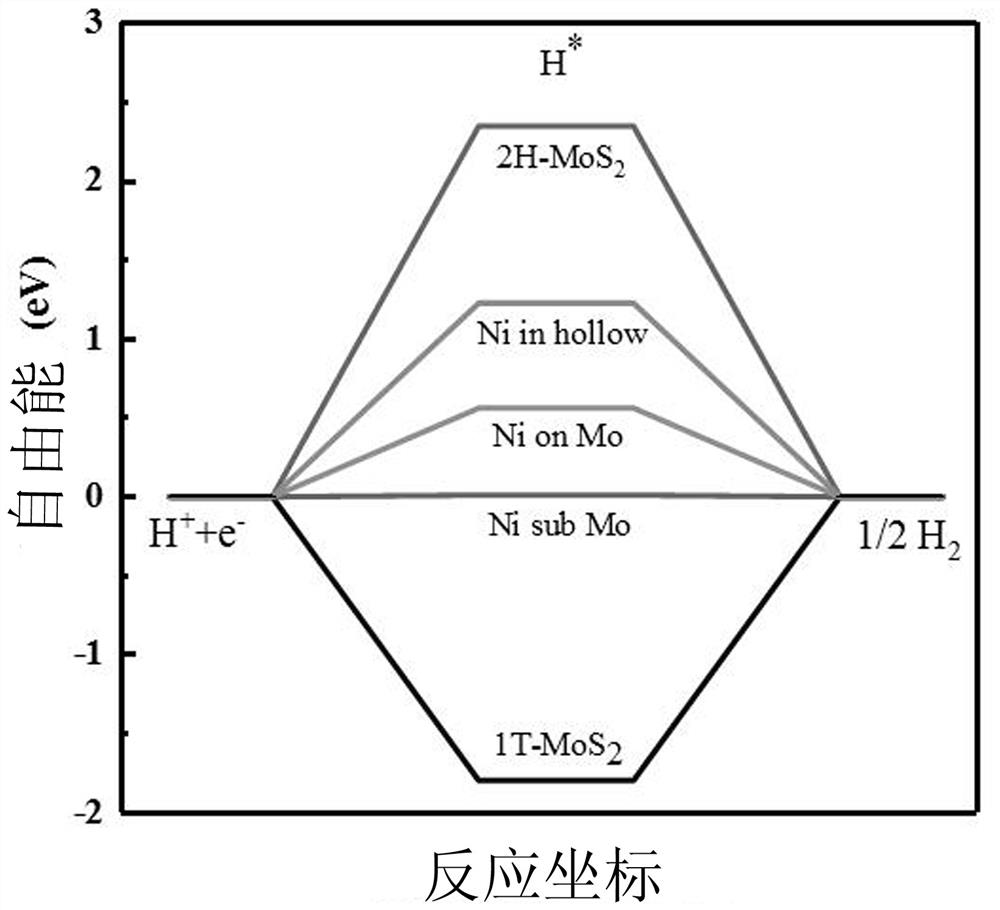

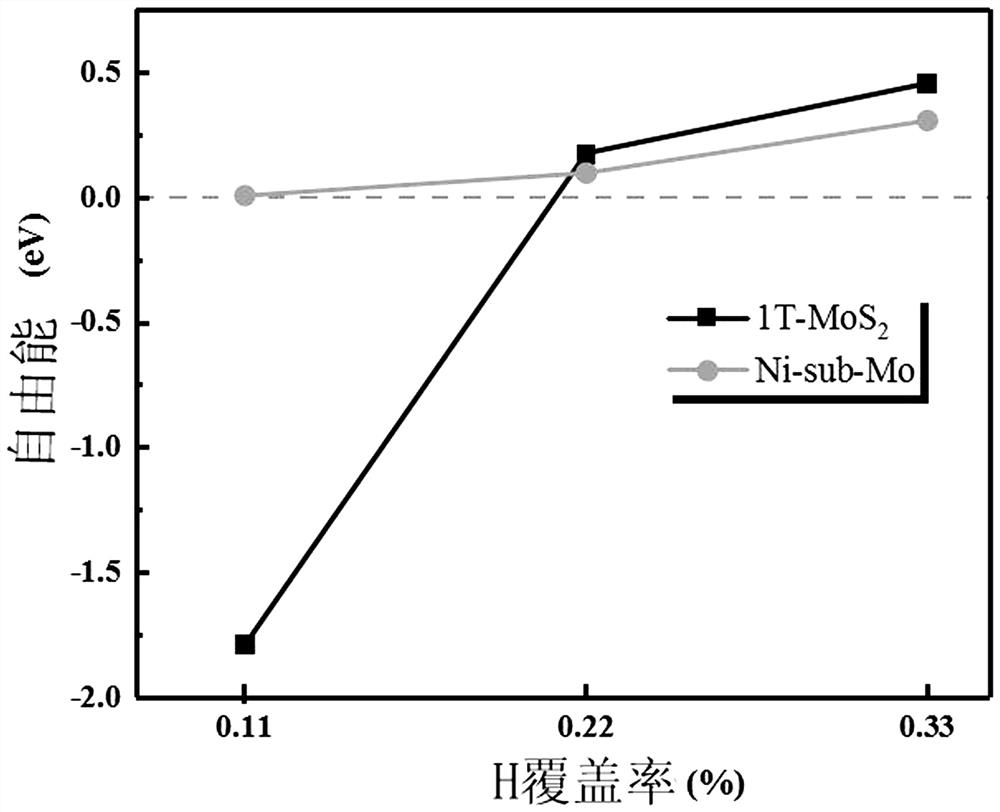

[0020] 2H-phase MoS 2 The catalytic hydrogen evolution performance of two-dimensional materials only exists at its edge sites, and the surface is catalytically inert, which is extremely unfavorable for its application in catalytic reactions. After converting to 1T phase, although the surface has obtained a certain catalytic activity, but Its performance is still poor and greatly affected by the surface coverage of H.

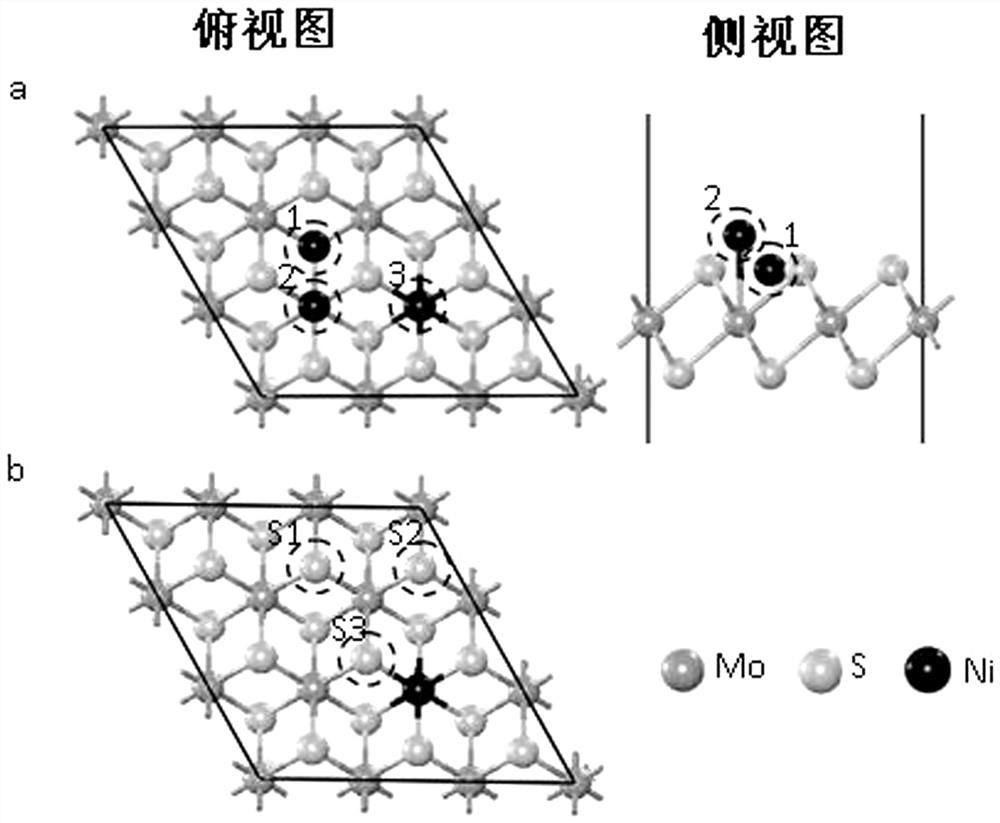

[0021] A method to improve the performance of molybdenum disulfide catalytic hydrogen evolution, using the first-principle density functional theory, using the VESTA material model construction software, to construct several difference models of different phases and different Ni doping sites, using the Vienna Abinitio Simulation Package That is, VASP software, for Ni-doped 1T phase MoS 2 The catalytic hydrogen evolution performance was characterized, and the Ni-doped 1T phase MoS with improved catalytic hydrogen evolution performance was obtained 2 .

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com