An optimal scheduling method for motor commutator production process

A motor commutator and optimized scheduling technology, applied in the direction of instruments, data processing applications, manufacturing computing systems, etc., can solve the problems of not being able to better optimize the maximum completion time and difficult scheduling, so as to reduce production costs and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

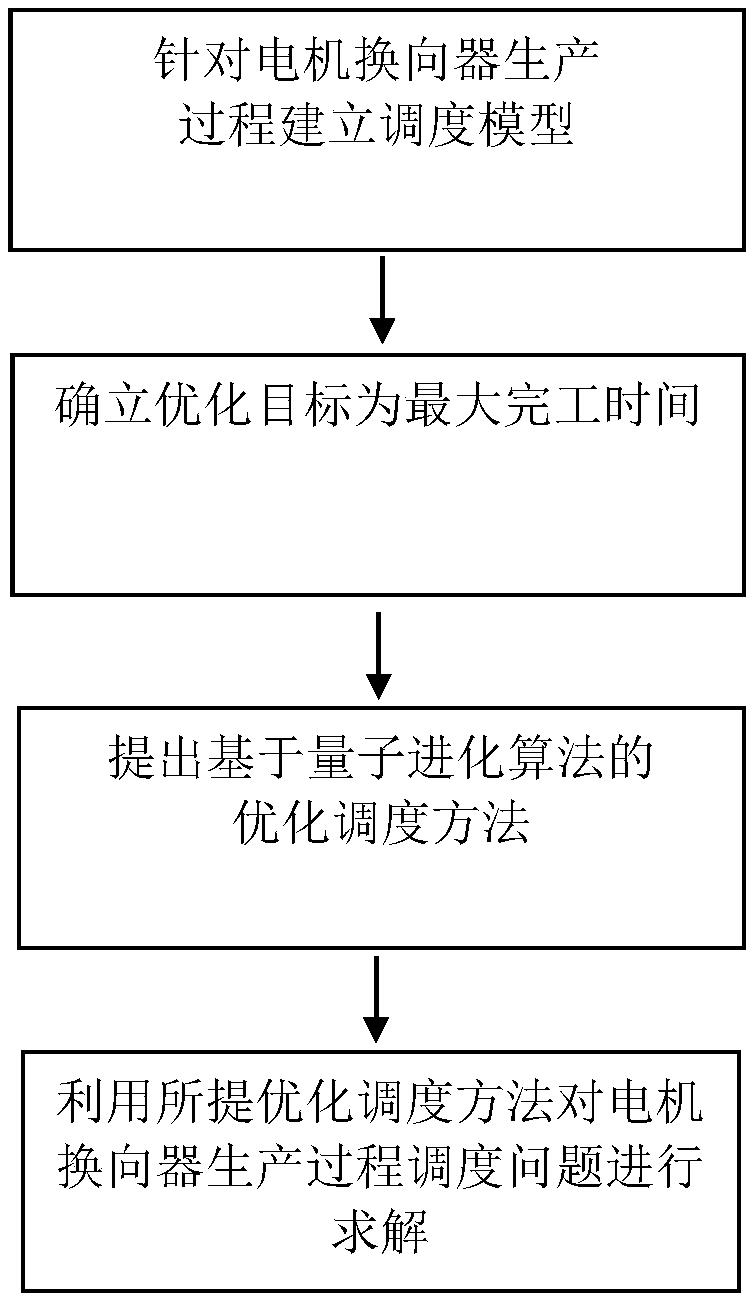

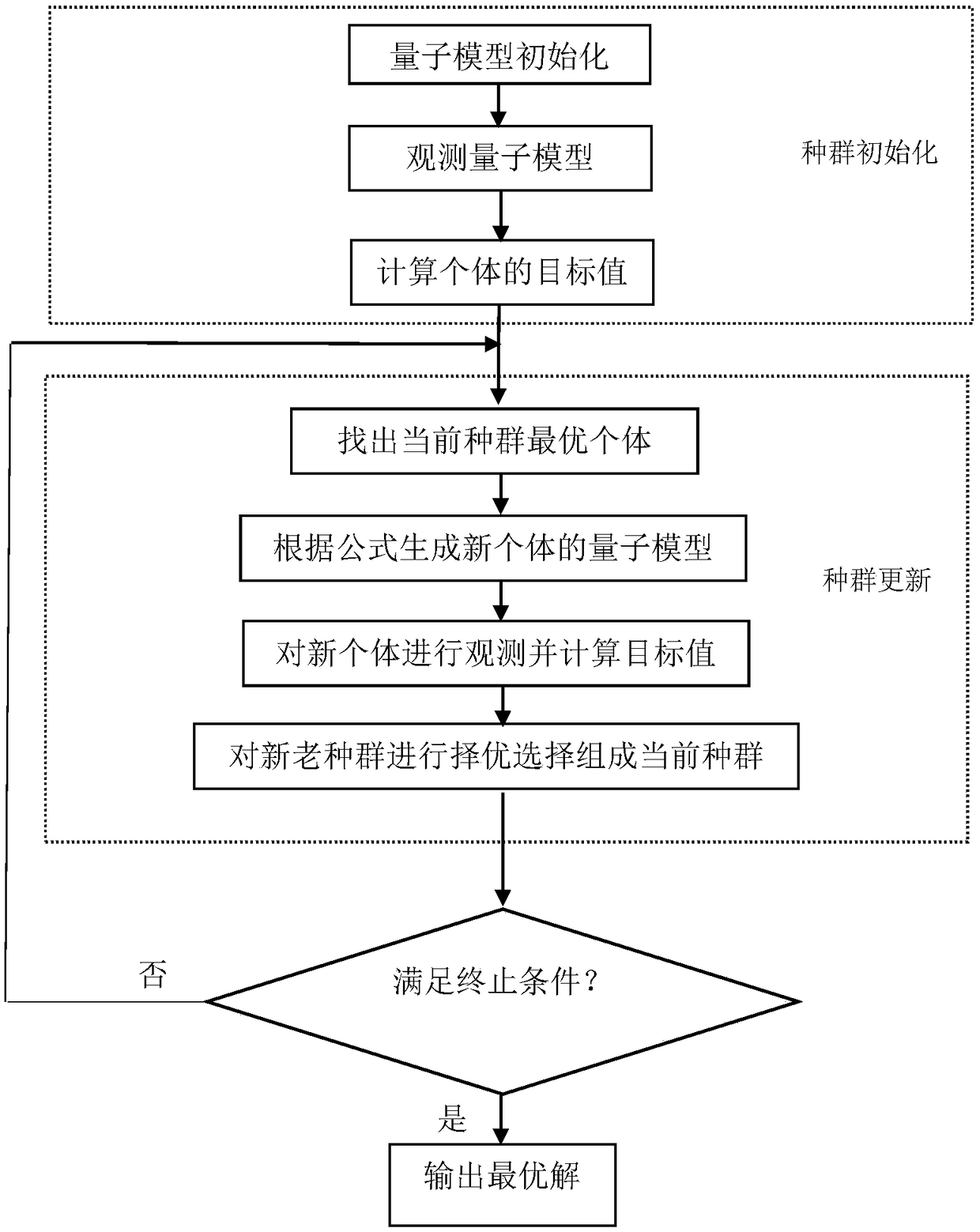

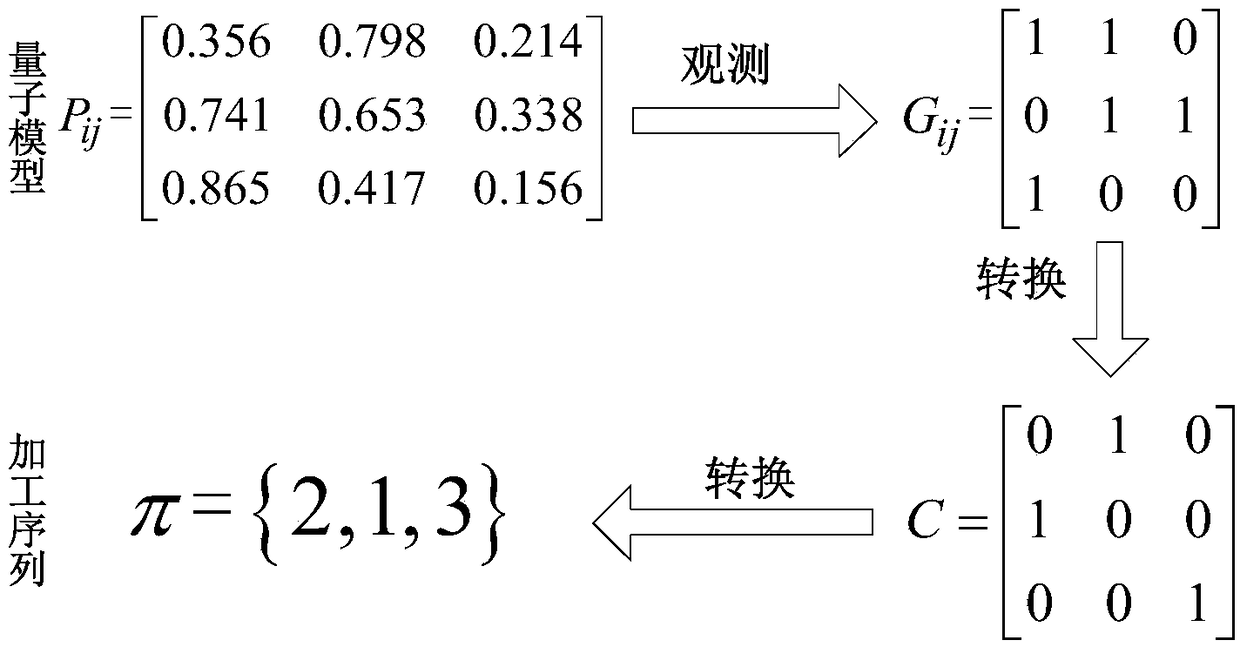

[0028] Embodiment 1: as Figure 1-3 As shown, an optimal scheduling method for the production process of motor commutators, by determining the scheduling model and optimization objectives in the production process of motor commutators, and proposes an optimal scheduling method based on quantum evolutionary algorithms to optimize the objectives ; Among them, the scheduling model is established according to the processing time of each specification commutator and the number of processes required for the production of the motor commutator, and the optimization goal is determined to minimize the maximum completion time, that is, f=C max (π);

[0029]

[0030]

[0031]

[0032]

[0033]

[0034] In the formula, the number of specifications of the motor commutator is n, and the number of required processing operations is m; π={π 1 , π 2 ,…,π n} represents a solution to the optimal scheduling problem, π i is the i-th batch of commutator products processed in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com