Method and device for producing volume-holographic anti-counterfeiting marks in batch

A technology of anti-counterfeiting marking and mass production, which is applied in the field of anti-counterfeiting, can solve problems such as restrictions, achieve a high degree of structural integration, and improve the effect of anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

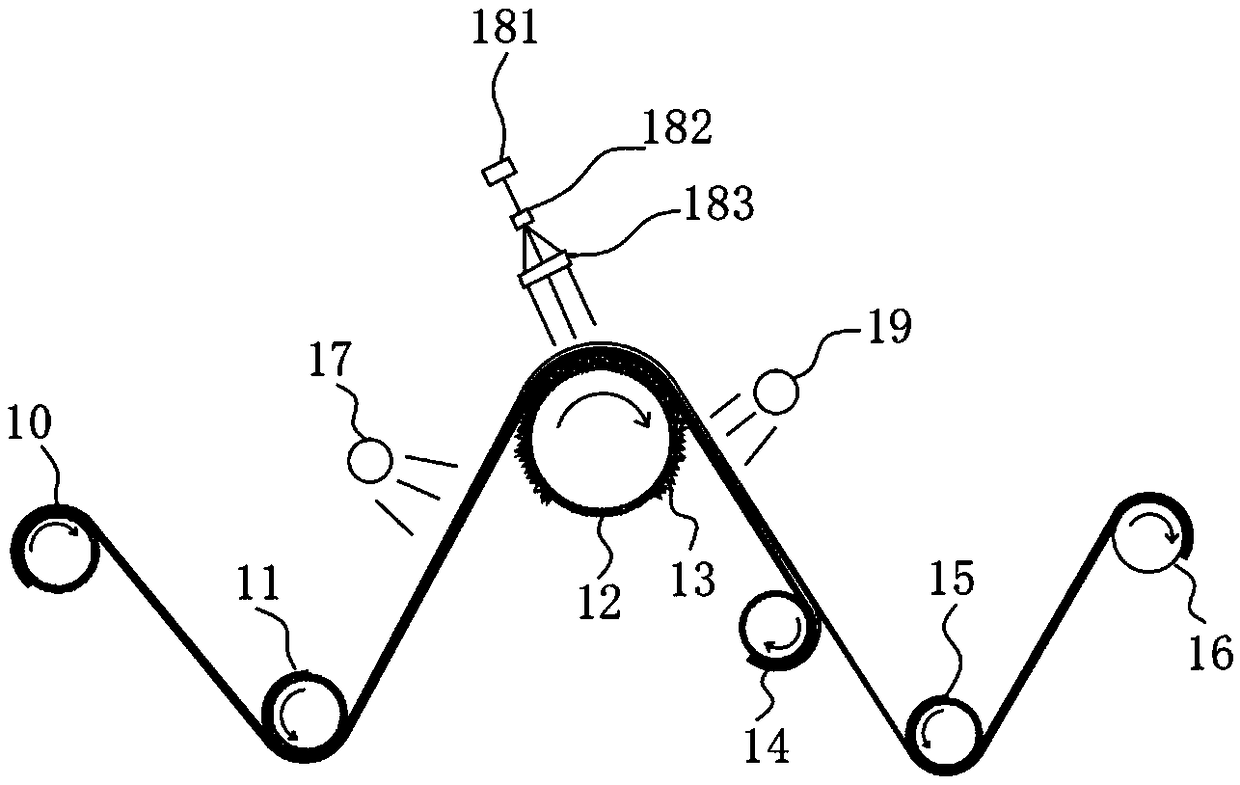

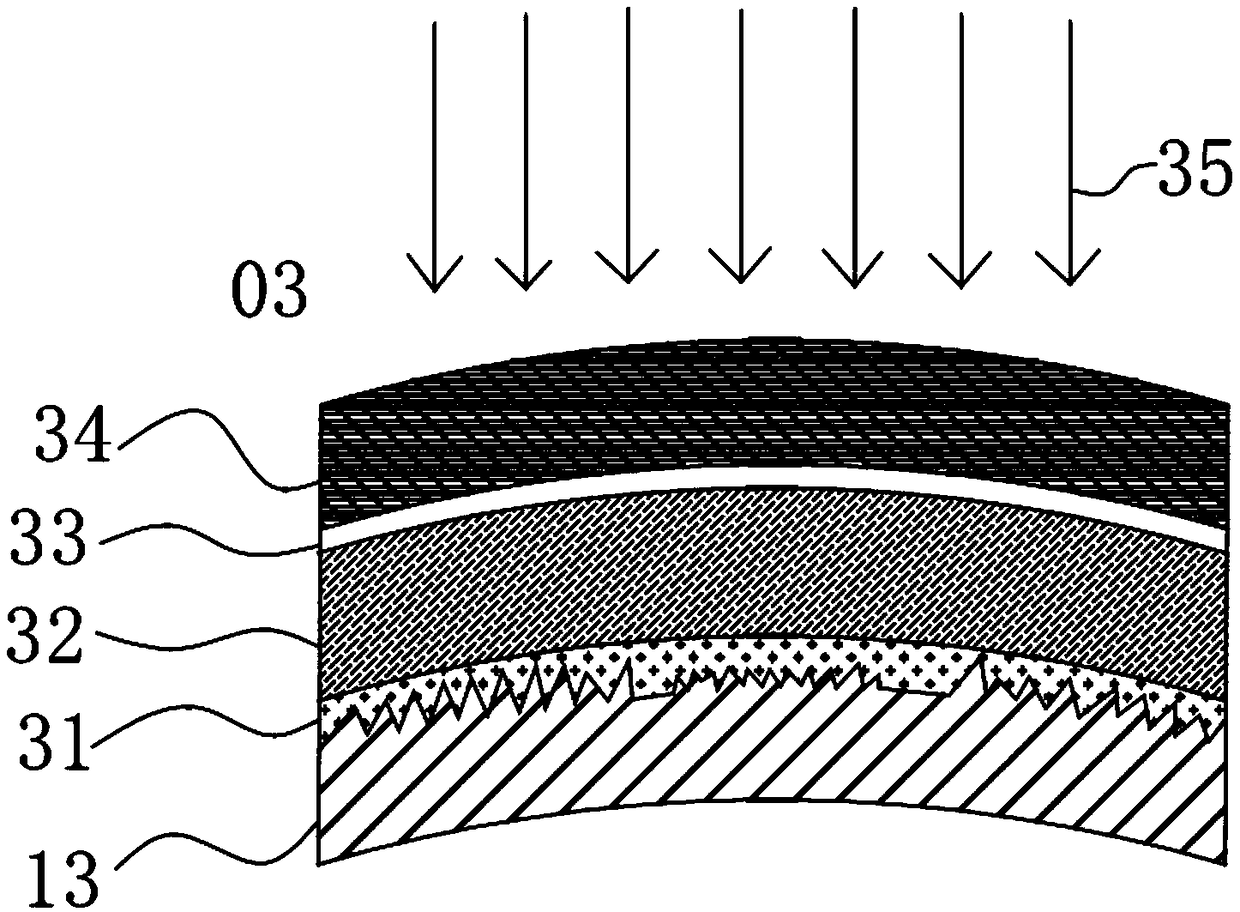

[0035] see figure 1 , The device for mass production of volume holographic anti-counterfeiting labels according to an embodiment of the present invention includes a surface holographic master, a film roll, a copy roll, and an exposure system.

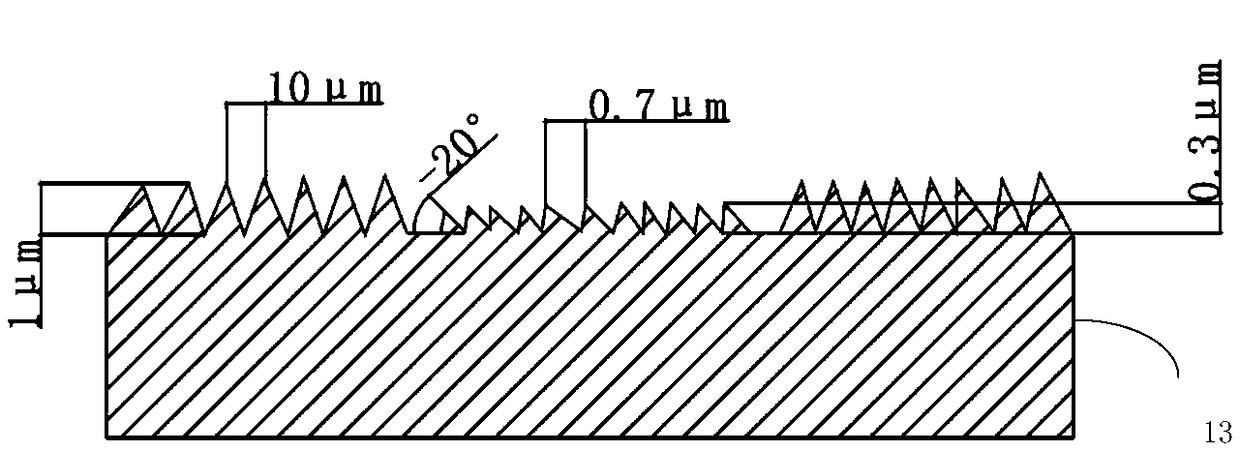

[0036] Wherein the film unwinding roll includes a first film unwinding roll 10, the first film unwinding roll 10 is used to release the base film, and the second film unwinding roll 11 is used for releasing the photosensitive recording medium film. Wherein, both sides of the base film are respectively coated with a release layer and an adhesive layer. Preferably, the thickness of the adhesive layer is greater than or equal to the grating depth of the surface holographic master, and the maximum thickness is not greater than 10 μm. The adhesive layer is Transparent photosensitive colloid, preferably uv glue, base film is preferably PET film. The photosensitive recording medium thin film is laminated on the release layer of the base film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com