A vertical cavity surface-emitting laser chip and a manufacturing method thereof

A vertical cavity surface emission and chip technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of unfavorable VCSEL chip application and large half-wave width, and achieve the effect of increasing current density and reducing half-wave width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

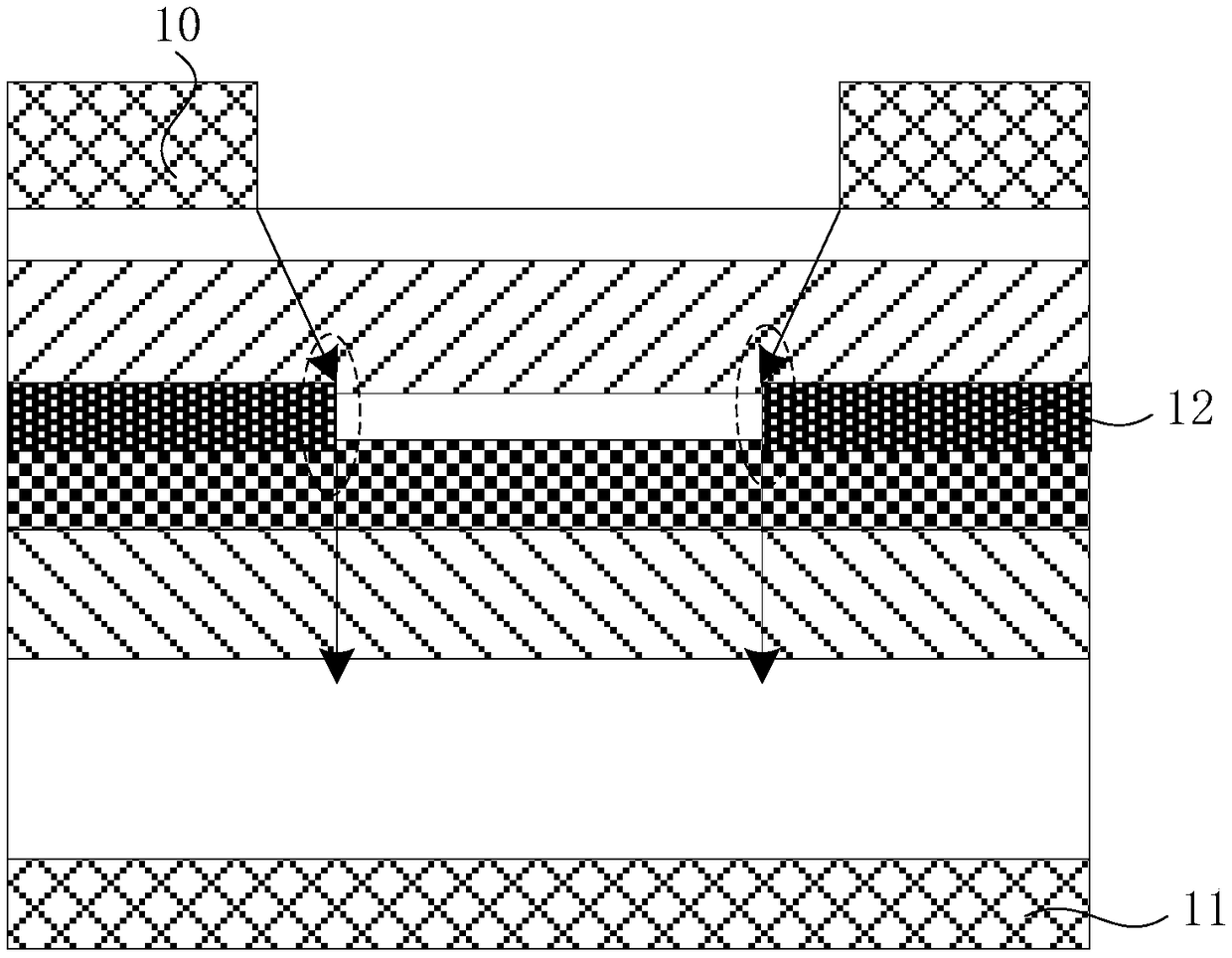

[0026] As mentioned in the background art, the half-wave width of the existing VCSEL chip is relatively large. Such as figure 1 As shown, the inventors have found that the reason for this problem is that in the process of current flowing from the negative electrode 10 to the positive electrode 11, due to the shortest path effect of the current, the current is in the edge region of the unoxidized region of the oxide layer 12 ( (in the dotted line box) is too concentrated, resulting in a small current density in the central area of the unoxidized region, which in turn leads to a certain difference in the wavelength of the laser emitted by the chip, resulting in a large half-wave width.

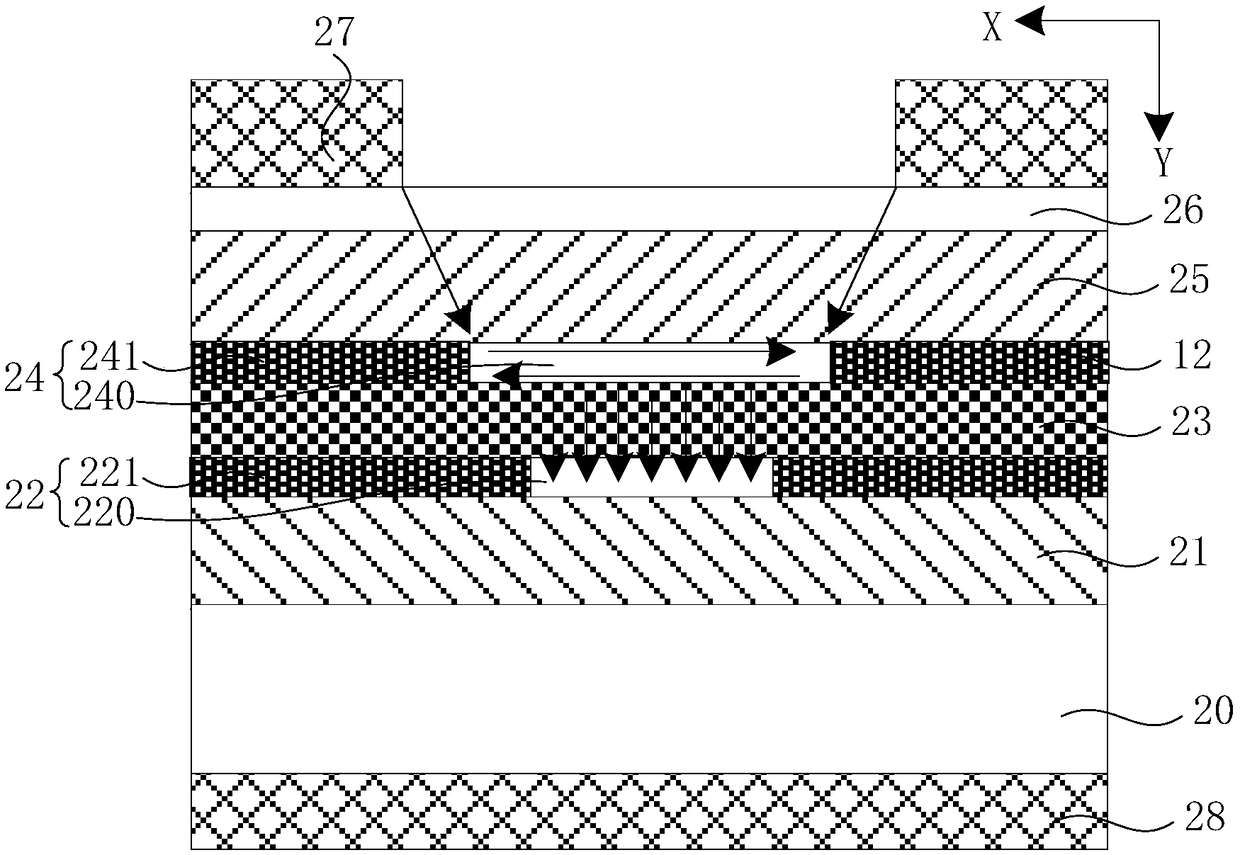

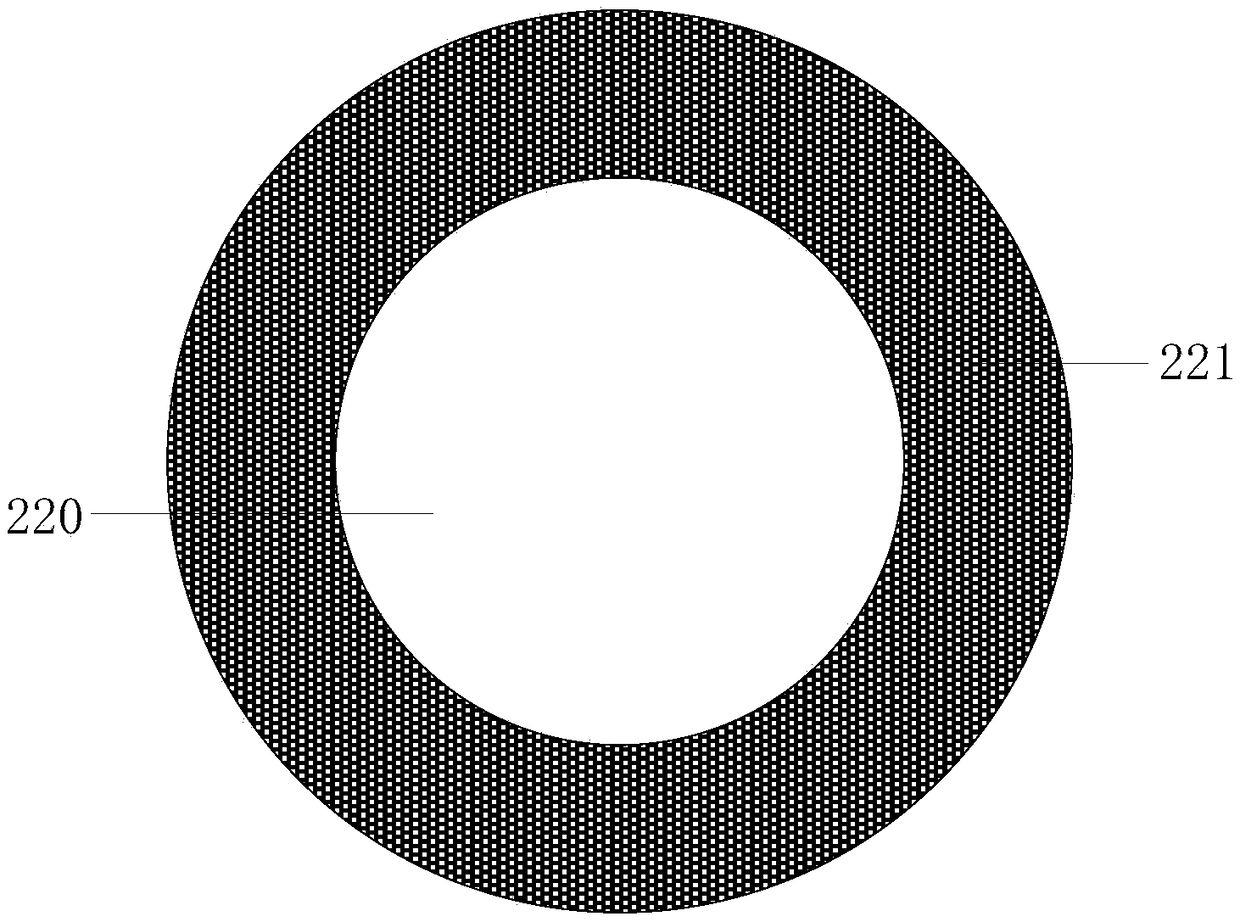

[0027] Based on this, the present invention provides a vertical cavity surface emitting laser chip and a manufacturing method thereof to overcome the above-mentioned problems existing in the prior art, including a substrate, an N-type DBR layer sequentially located on the first surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com