Paper diaper with grid type absorption body and method for preparing paper diaper

A technology for absorbing the main body and diapers, which can be used in absorbent pads, medical science, clothing, etc. It can solve the problems of uneven water absorption, uneven spraying, displacement, etc., and achieve the effects of rapid absorption, excellent drainage, and good stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

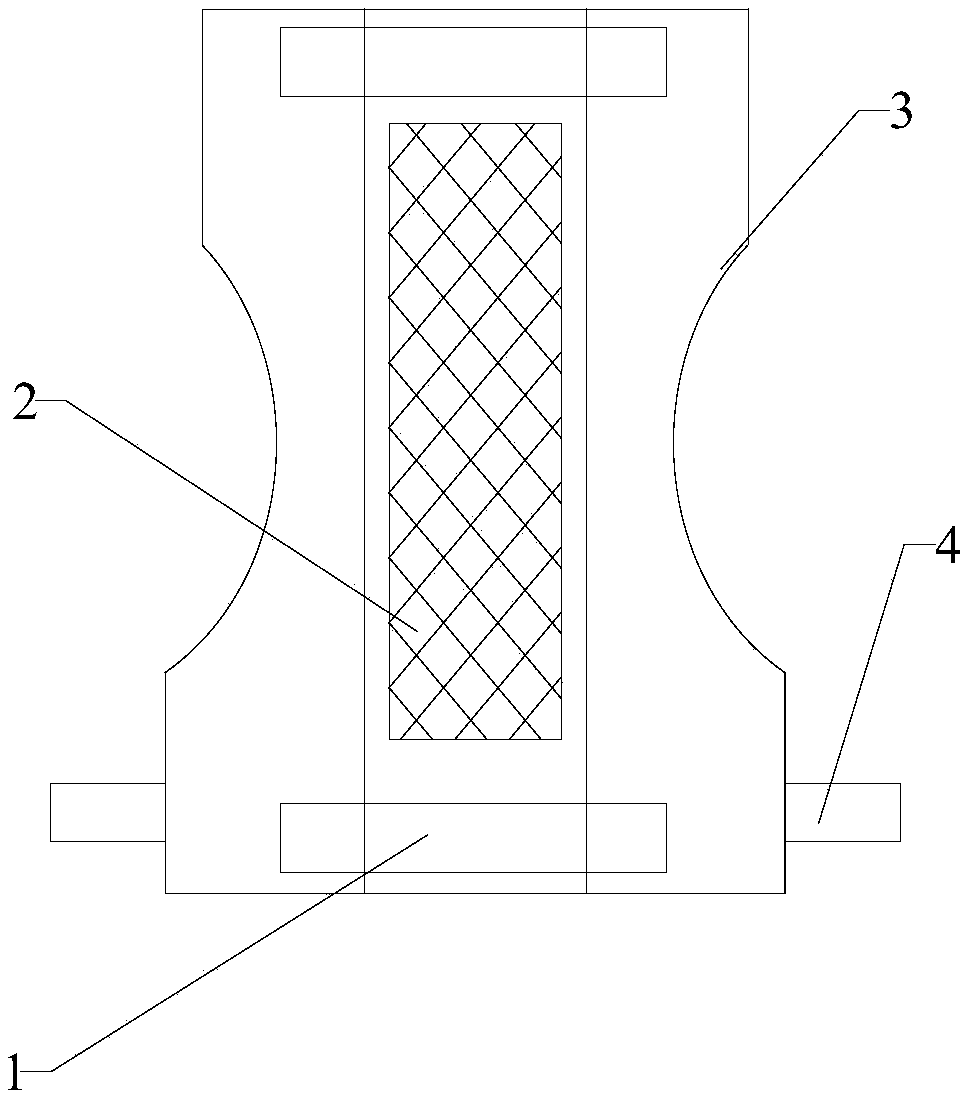

[0031] A paper diaper with a grid-type absorbent body, comprising a surface layer, a grid-type absorbent body, a leak-proof bottom film and a cloth-like bottom layer arranged sequentially from top to bottom;

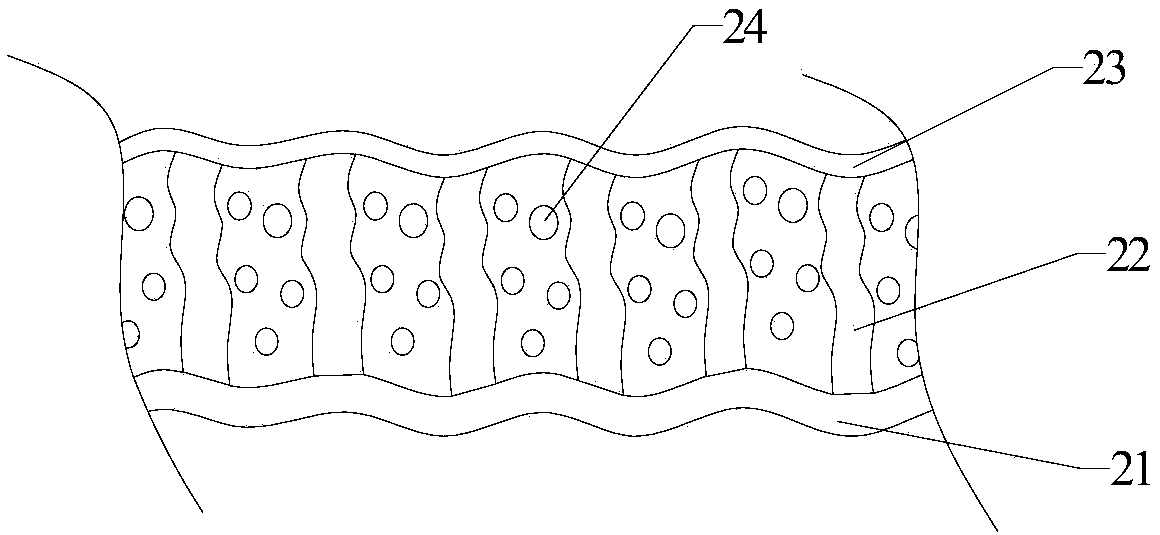

[0032] The grid-type absorbent main body includes a three-dimensional grid guide cloth, and the three-dimensional grid guide cloth includes a first guide non-woven fabric, a mesh cloth and a second guide non-woven fabric, and the mesh cloth is The guide fiber is a woven or knitted fabric evenly distributed with meshes made of raw materials by weaving or knitting. The meshes are sprinkled with polymer water-absorbing resin particles. The covers are respectively provided with a first flow-guiding non-woven fabric and a second flow-guiding non-woven fabric.

[0033] The guide fiber is PE / PET composite fiber or bamboo fiber. The first flow-guiding non-woven fabric is made of bamboo fibers, and the second flow-guiding non-woven fabric is made of bamboo fibers.

[0034] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com