Microfluidic reaction chip, liquid droplet positioning control system based on same and control method

A microfluidic reaction and positioning control technology, applied in fluid controllers, chemical instruments and methods, laboratory utensils, etc., can solve the problem of inability to observe the driving process of microdroplets, and achieve the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

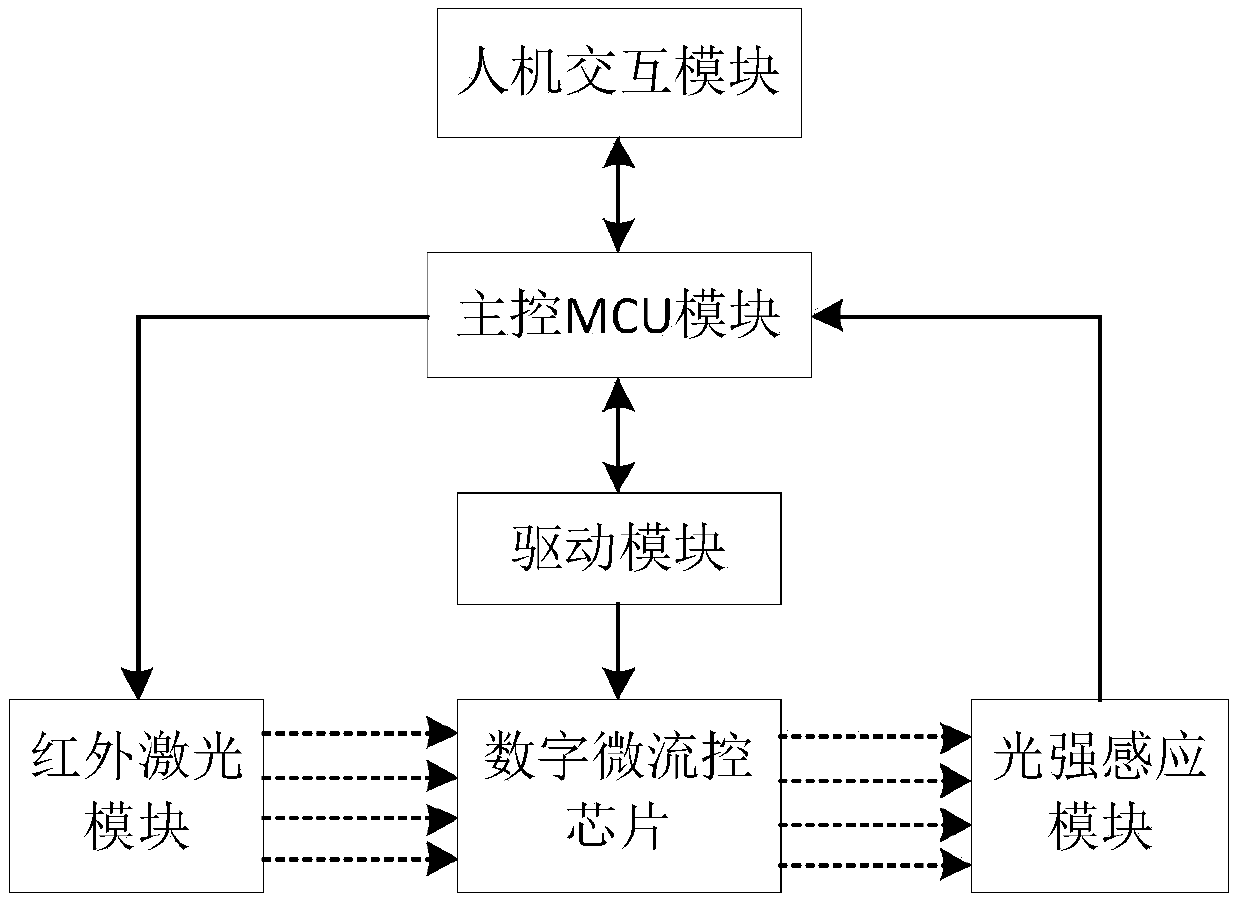

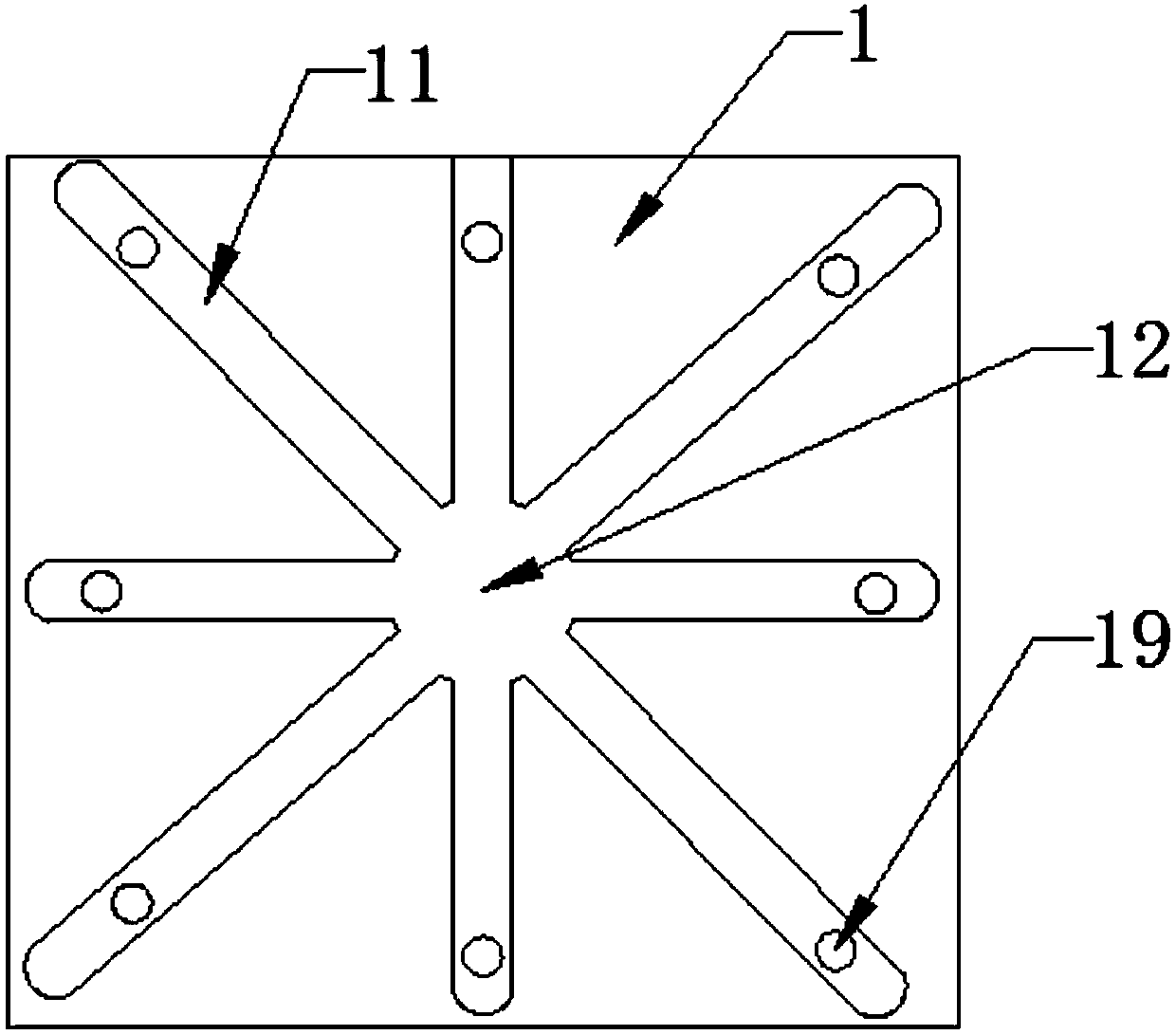

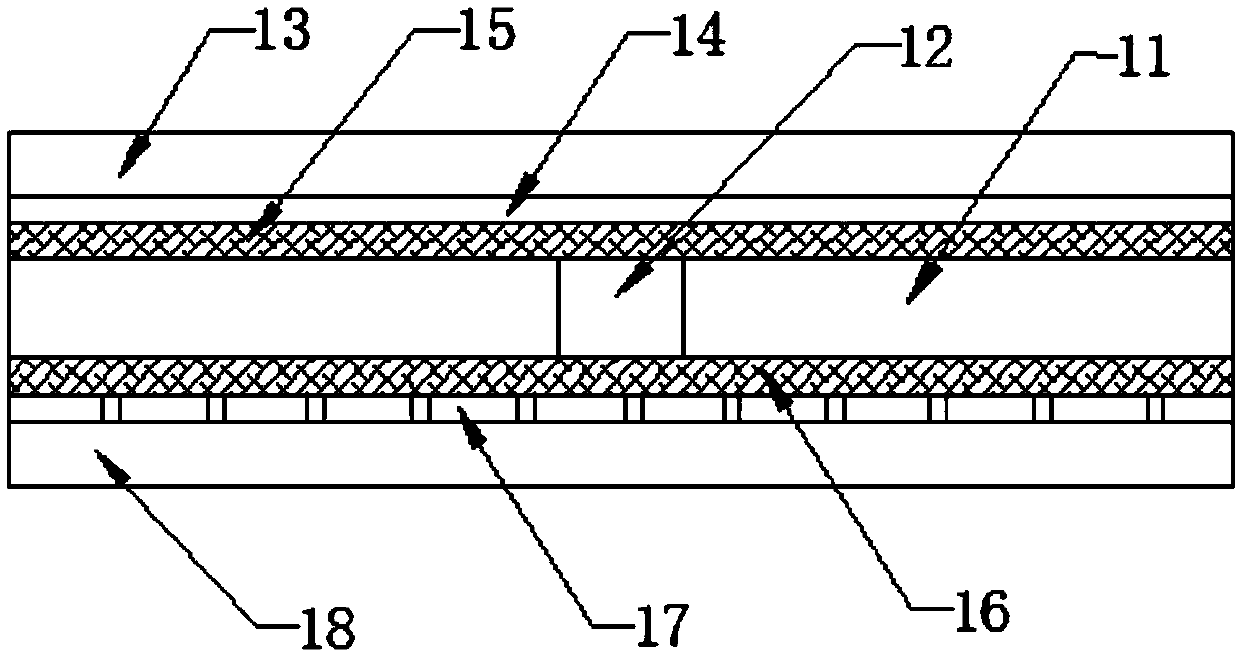

[0064] Such as figure 2 , image 3 As shown, a microfluidic reaction chip is characterized in that: it includes a square digital microfluidic chip 1, and the digital microfluidic chip 1 includes an upper pole plate and a lower pole plate, and the upper pole plate is sequentially arranged from top to bottom Composed of an upper substrate 13, a zero electrode layer 14 and an upper hydrophobic dielectric layer 15, the lower plate is composed of a lower hydrophobic dielectric layer 16, a driving electrode layer 17 and a lower substrate 18 from top to bottom; wherein, as Figure 5 As shown, the driving electrode layer 17 is composed of eight driving electrode units; seven droplet channels 11 are formed between the upper plate and the lower plate, and the junction of each of the droplet channels 11 is Reaction tank 12; a titration hole 19 is provided above each of the droplet flow channels 11, and the titration hole 19 runs through the upper plate; one of the droplet flow channels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com