A continuous and rapid unloading device for chain plate automatic processing production line

An automatic processing and production line technology, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of asynchronous operation of the upper die, inconvenient steel belt transportation, leakage of materials, etc., and achieve reasonable structural design and convenient material reclaiming. Fast, accurate and convenient delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

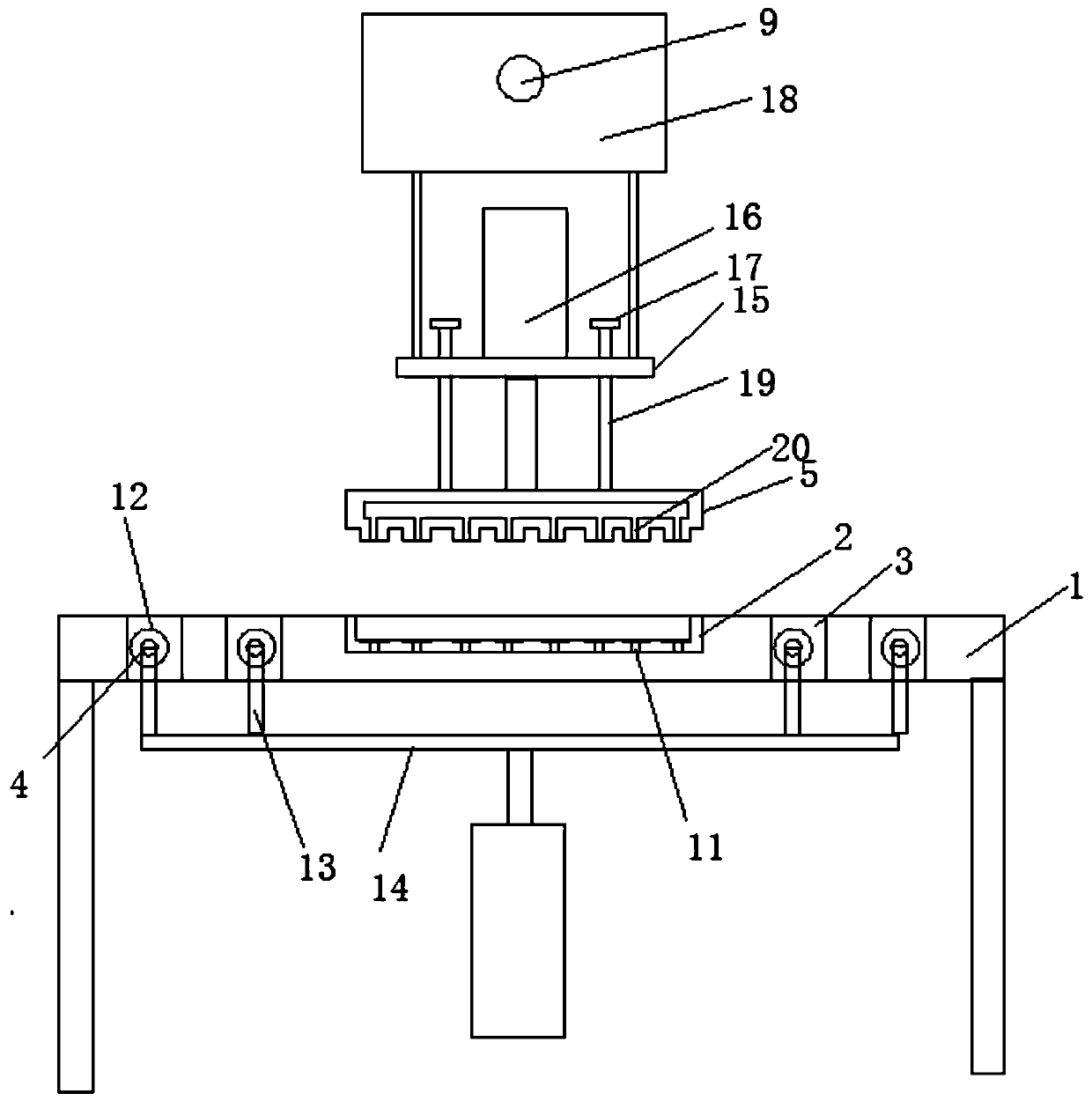

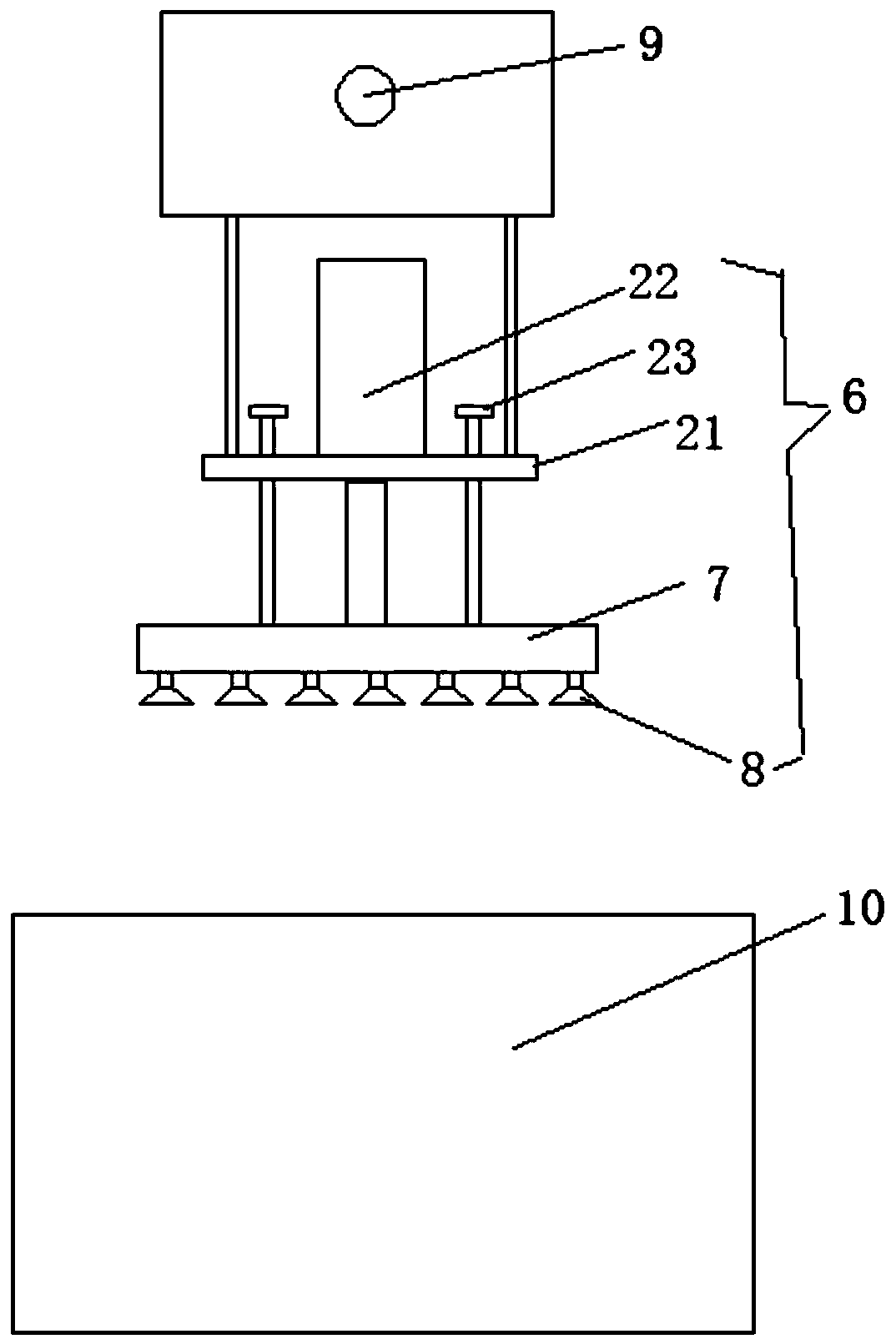

[0015] See attached picture.

[0016] A continuous rapid blanking device for a chain plate automatic processing production line, including a workbench 1, a lower mold 2 is installed on the workbench 1, and mold cavities distributed in an array are evenly distributed on the lower mold 2, so that The two sides of the workbench outside the lower mold 2 are distributed with openings 3 arranged at intervals. Liftable conveying rods are respectively installed in the openings 3. A movable upper mold 5 and a movable upper mold are erected above the workbench 1. The material retrieving mechanism 6, the lower end surface of the upper mold 5 is distributed with pressure heads corresponding to the cavity of the lower mold 2 and distributed in a display style. The material reclaiming mechanism 6 includes a material retrieving plate 7. The lower end surface of 7 is distributed with the sucker 8 that is the display type distribution that matches with lower mold 2 mold cavity correspondingly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com