Fully automatic double-ended saw

A fully automatic, double-ended technology, used in circular saws, sawing equipment, wood processing appliances, etc., can solve the problems of low manual operation safety, inconvenient and flexible use, high production costs, and achieve high work efficiency and processing accuracy. , safe and convenient to use, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

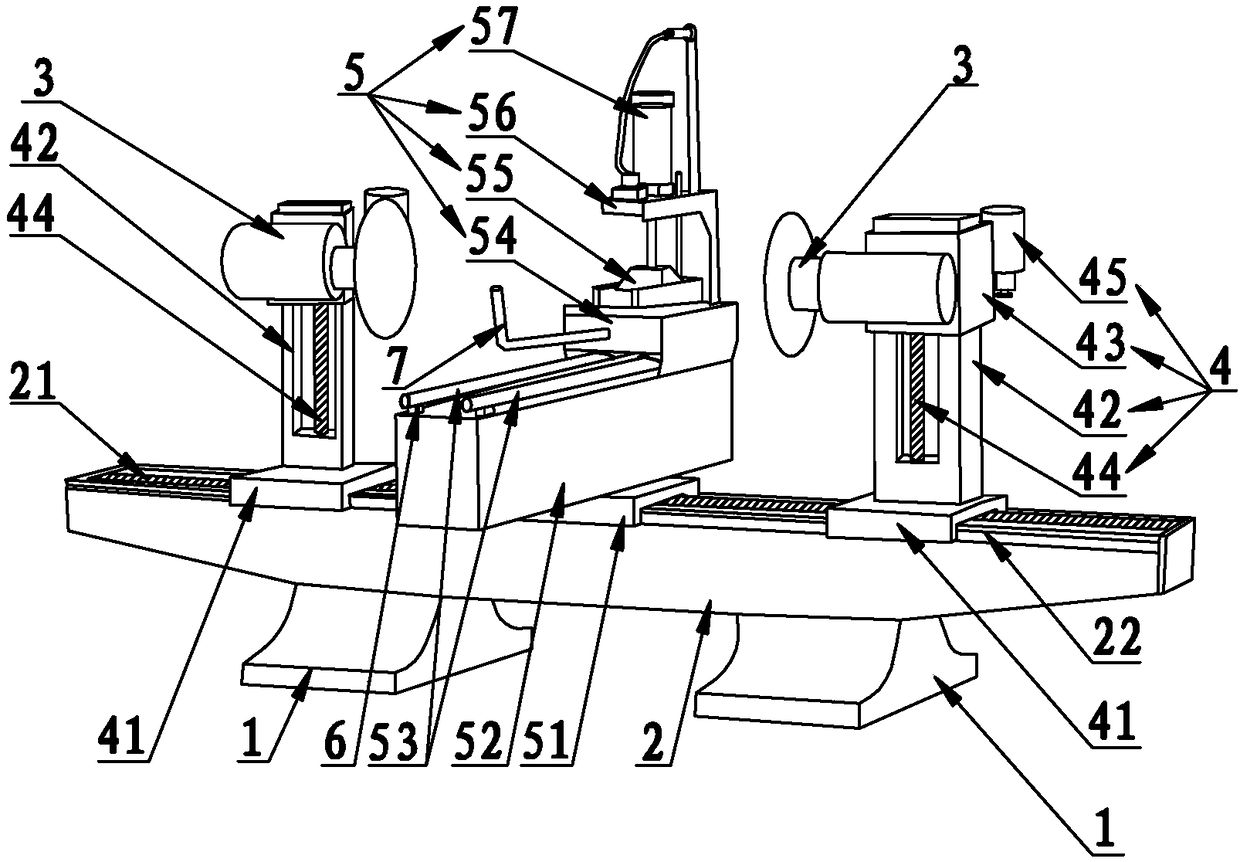

[0032] Such as Figure 1-3 As shown, a fully automatic double-ended saw includes a support base 1, a chute 2, an electric circular saw 3, a lifting mechanism 4 and a clamping device 5; the chute 2 is horizontally arranged, and the chute 1 The front and rear sides of the upper end are provided with dovetail grooves 22, and the left and right parts of the bottom surface of the chute-2 are symmetrically provided with the support seat 1; the inner left and right sides of the chute-2 are horizontally arranged Two leading screw one 21, described two leading screw one 21 are all on the same horizontal line, the outer sides of described two leading screw one 21 are all socketed with the screw nut (not shown in the figure) that matches with it, described The left end of left side leading screw-21 and the right end of right leading screw-21 all are equipped with servomotor (not shown in the figure) by shaft coupling; There is the lifting mechanism 4;

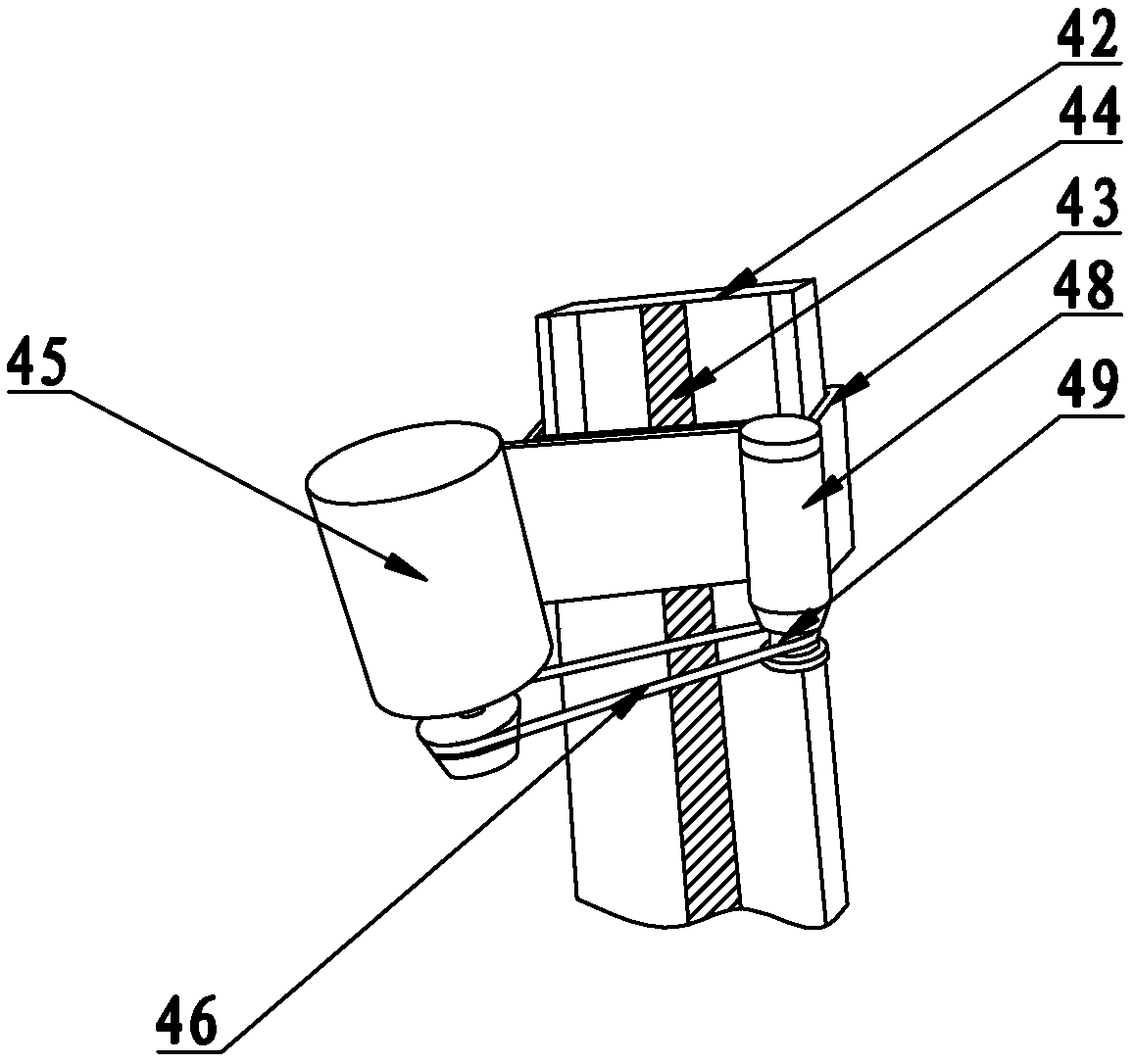

[0033] Described elevating mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com