Logistics tray with hydraulic jacking wheels

A technology of logistics and pallets, which is applied in the field of logistics pallets with hydraulic ejection wheels, can solve problems such as difficult to realize, time-consuming and labor-intensive, and unfavorable for the rapid development of logistics, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

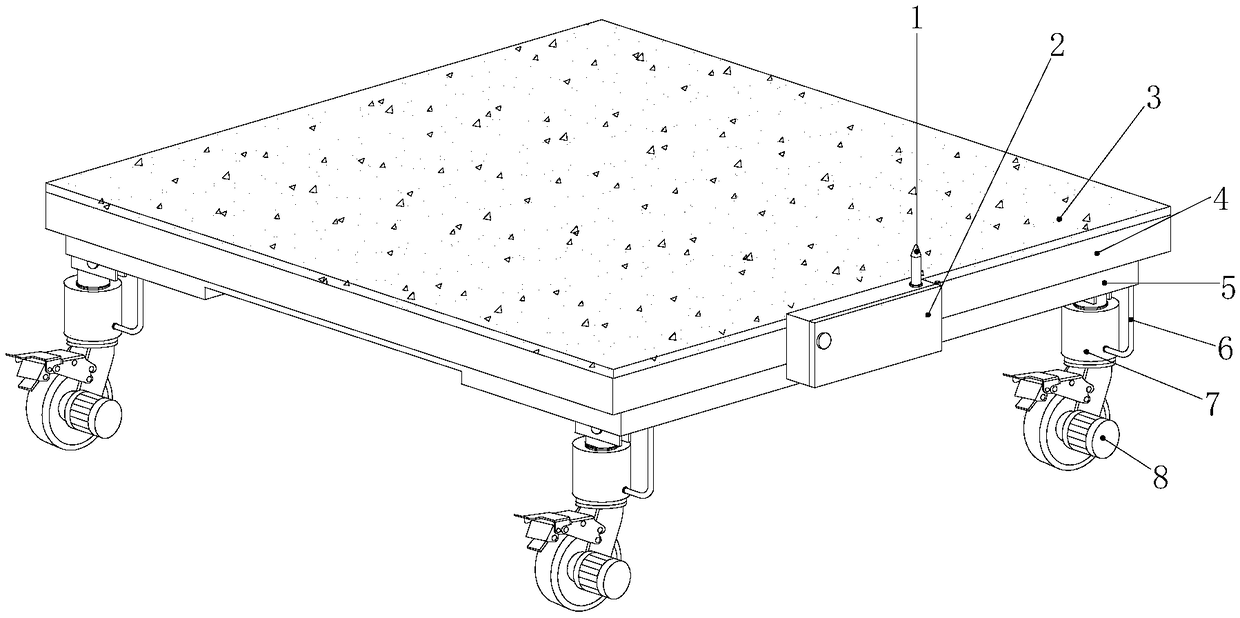

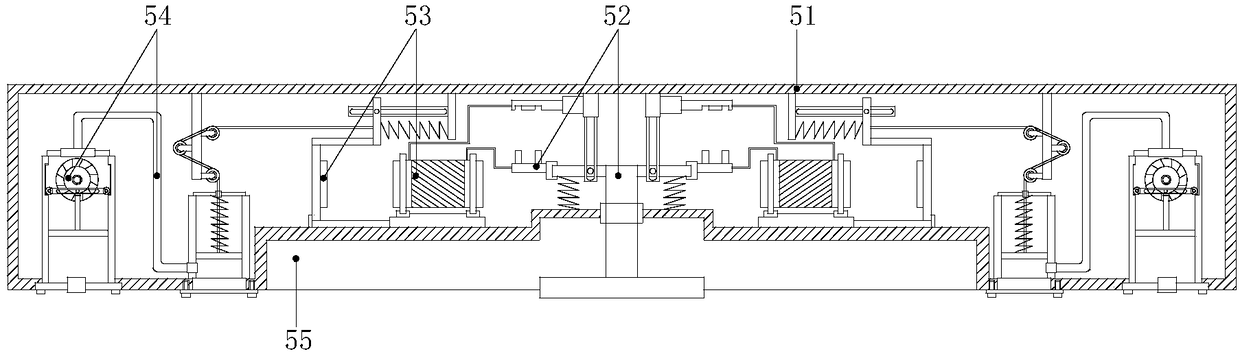

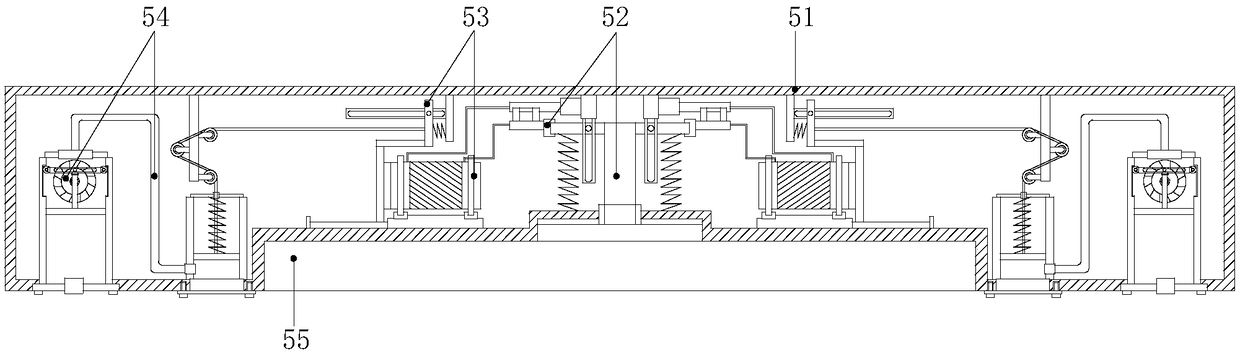

[0021] see Figure 1-Figure 4, the present invention provides a logistics pallet with a hydraulic ejection wheel, its structure includes a wireless signal receiver 1, a data processing control cabinet 2, an anti-slip rubber layer 3, a logistics pallet 4, a transmission jacking device 5, and a hydraulic connection hose 6 , hydraulic cylinder 7, electric casters 8, the top of the logistics tray 4 is provided with an anti-slip rubber layer 3 and the two adopt interference fit, and the side of the logistics tray 4 is provided with a data processing control cabinet 2 and the two are interlocked Together, the top of the data processing control cabinet 2 is provided with a wireless signal receiver 1 and the two are threaded, and the center of the bottom of the logistics tray 4 is provided with a transmission jacking device 5, and the bottom surface of the logistics tray 4 is connected to the The top surface of the transmission jacking device 5 adopts interference fit, and the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com