Fully-enclosed horizontal type coal storage tank system

A fully enclosed, horizontal technology, used in loading/unloading, containers, packaging, etc., can solve the problems of increased civil engineering and equipment investment, large floor space, and increased investment, so as to improve site utilization and save floor space. , the effect of reducing investment cost

Pending Publication Date: 2018-12-28

黄羽

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional strip-shaped coal yard occupies a huge area, and the investment will increase significantly after the closed structure is added; the circular coal yard, spherical coal yard, and square closed coal yard can save part of the occupied area, but the investment in civil engineering and equipment will increase significantly ; Cluster silos can accurately blend coal, but the cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

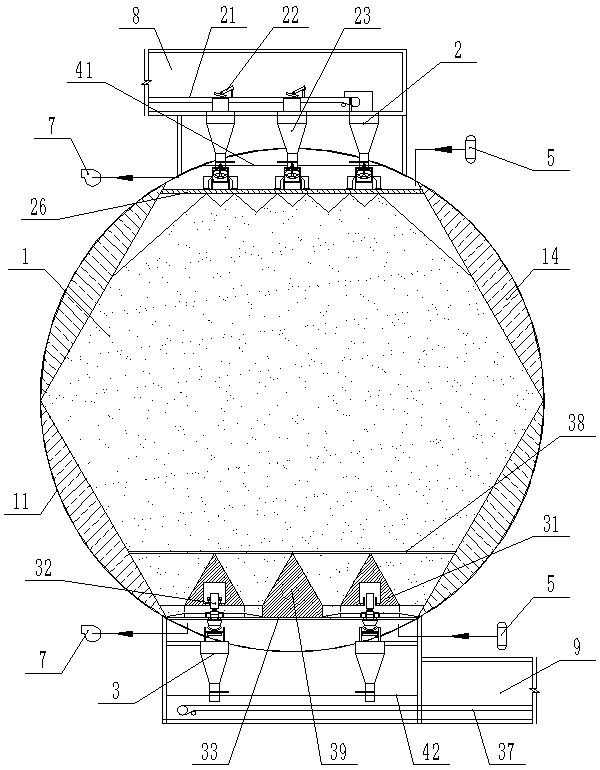

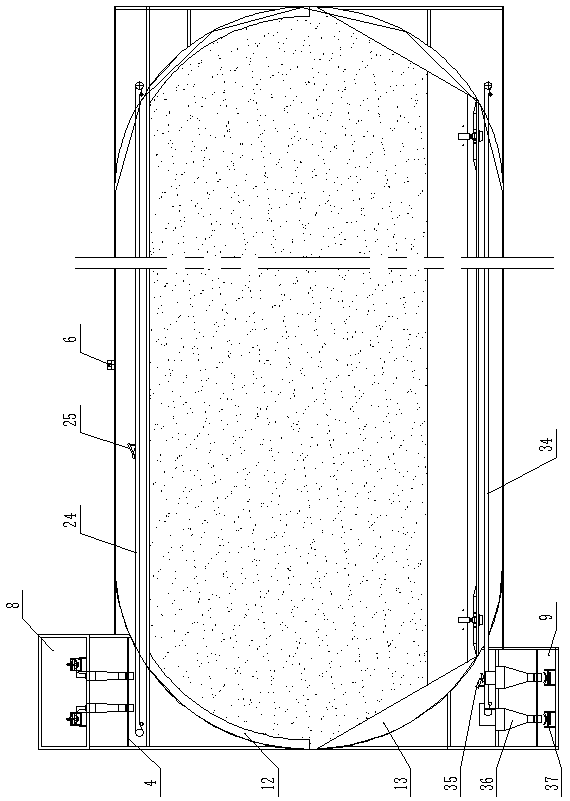

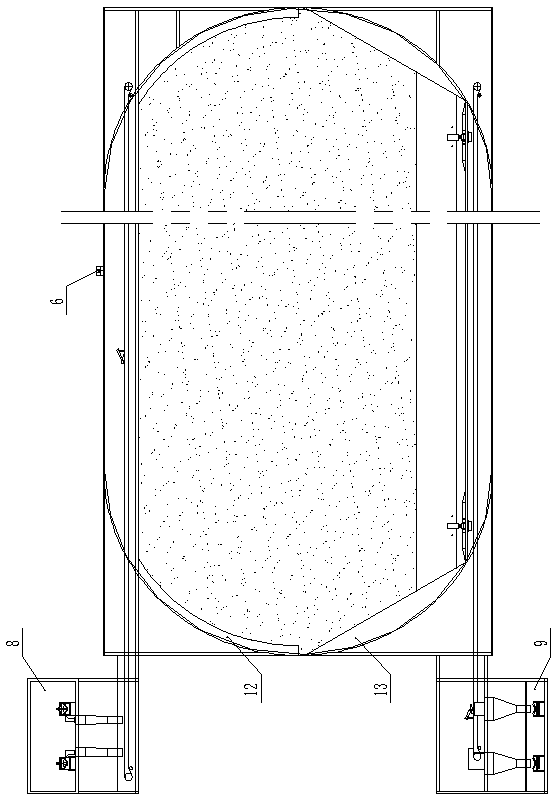

The invention discloses a fully-enclosed horizontal type coal storage tank system and belongs to the technical field of coal storage devices. The fully-enclosed horizontal type coal storage tank system solves the technical problems of saving investment, reducing space occupation and achieving high space utilization rate. According to the technical scheme, the fully-enclosed horizontal type coal storage tank system comprises a round storage tank system, a feeding system, a discharging system and a sealing system, wherein the round storage tank system is a horizontal cylindrical tank; the feeding system comprises a feeding belt, a feeding plough type discharging unit, a feeding bucket, an internal distributing belt and a movable discharging cart; the discharging system comprises a coal stopping prism, an impeller feeding machine, a bottom plate, an internal discharging belt, a discharging plough type discharging unit, a discharging bucket and a discharging belt; the sealing system comprises a feeding end sealing plate and a discharging end sealing plate; the feeding system is arranged at the feeding port of the cylindrical tank, and the discharging system is arranged at the discharging port of the cylindrical tank. The fully-enclosed horizontal type coal storage tank system is a fully-enclosed coal storage device.

Description

technical field The invention discloses a fully enclosed horizontal coal storage tank system, which belongs to the technical field of coal storage devices, and in particular relates to a fully enclosed horizontal coal storage tank with a loading and unloading mechanism. Background technique With the improvement of the country's environmental governance requirements, coal mines, ports, power plants, etc. are in urgent need of a fully enclosed coal yard solution that is environmentally friendly, safe, and investment-saving. At the same time, projects that do not use fully enclosed coal yards are forced to transform into fully enclosed coal yards demand. At the same time, in the field of coal-fired power plants, with the continuous expansion of domestic coal-fired unit capacity and construction scale, and increasingly stringent environmental protection requirements, the design requirements for coal storage yards are also getting higher and higher. People are paying more and mo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65D90/12B65D88/54B65D90/00B65G65/32B65G65/42B65G69/04

CPCB65D88/546B65D90/00B65D90/12B65G65/32B65G65/42B65G69/04

Inventor 黄羽王为明李兵冯志波詹海英张广利杨子和刘必旭张辉

Owner 黄羽

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com