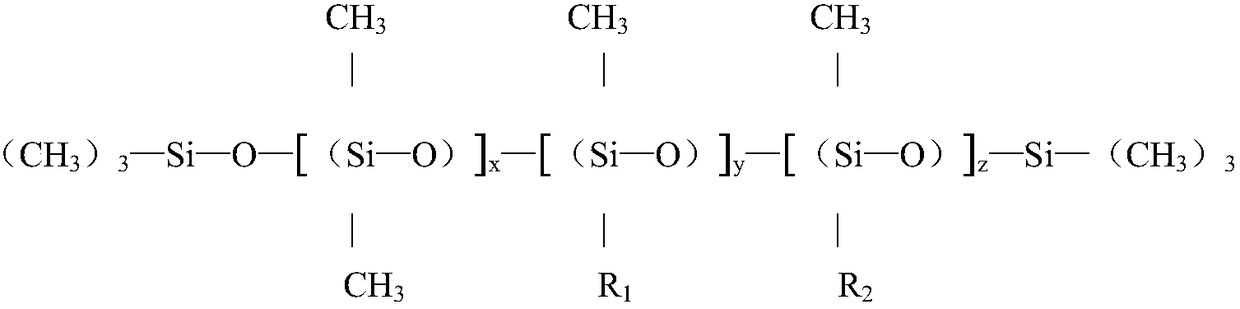

Preparation method of wood-imitated polyurethane foam stabilizer

A technology of polyurethane foam and stabilizer, applied in the field of imitation wood polyurethane foam stabilizer and its preparation, can solve the problems of reduced foam nucleation and foam stability, destruction of ozone layer, poor fluidity, etc. Reduces bubbles and promotes good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

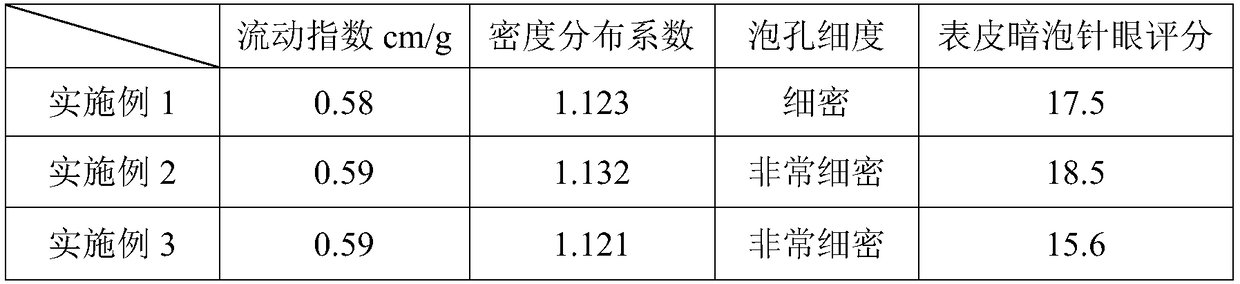

Embodiment 1

[0029] The preparation method of imitation wood polyurethane foam stabilizer comprises the following steps:

[0030] 1) Add 100g of octamethylcyclotetrasiloxane, 5.6g of hexamethyldisiloxane, 30.6g of high hydrogen-containing silicone oil with a hydrogen content of 1.56%, and 8g of acid clay into the reaction kettle, and heat to 45°C for reaction 12 hours to obtain a low hydrogen content silicone oil with a hydrogen content of 0.35%;

[0031] 2) Add 20g of diethylene glycol, 90g of ethylene oxide, 280g of propylene oxide and 0.6g of KOH into the reaction kettle, raise the temperature to 110°C, control the pressure at 0.4Mpa, and react for 8 hours, when the pressure in the kettle drops to 0.1Mpa , cooling down to stop the reaction, neutralizing and filtering to obtain a small molecule glycol polyether dispersant;

[0032] 3) 0.35% low-hydrogen silicone oil, 8.5g dodecene, 150g molecular weight 1000 allyl alcohol polyether and 200g step 2) prepared small molecular glycol polyet...

Embodiment 2

[0034] The preparation method of imitation wood polyurethane foam stabilizer comprises the following steps:

[0035] 1) Add 100g of octamethylcyclotetrasiloxane, 3.2g of hexamethyldisiloxane, 25.6g of high hydrogen-containing silicone oil with a hydrogen content of 1.56%, and 8g of acid clay into the reaction kettle, and heat to 45°C for reaction 12 hours to obtain a low hydrogen content silicone oil with a hydrogen content of 0.31%;

[0036] 2) Add 20g of diethylene glycol, 100g of ethylene oxide, 200g of propylene oxide and 0.6g of KOH into the reaction kettle, raise the temperature to 110°C, control the pressure at 0.4Mpa, and react for 8 hours, when the pressure in the kettle drops to 0.1Mpa , cooling down to stop the reaction, neutralizing and filtering to obtain a small molecule glycol polyether dispersant;

[0037] 3) 50g of 0.35% low-hydrogen silicone oil prepared in step 1), 6.6g of dodecene, 140.4g of allyl alcohol polyether with a molecular weight of 1000 and 160g ...

Embodiment 3

[0039] The preparation method of imitation wood polyurethane foam stabilizer comprises the following steps:

[0040] 1) Add 100g of octamethylcyclotetrasiloxane, 2.6g of hexamethyldisiloxane, 18.6g of high hydrogen-containing silicone oil with a hydrogen content of 1.56%, and 8g of acid clay into the reaction kettle, and heat to 45°C for reaction 12 hours to obtain a low hydrogen content silicone oil with a hydrogen content of 0.35%;

[0041] 2) Add 20g of diethylene glycol, 100g of ethylene oxide, 200g of propylene oxide and 0.6g of KOH into the reaction kettle, raise the temperature to 110°C, control the pressure at 0.4Mpa, and react for 8 hours. When the pressure in the kettle drops to 0.1 Mpa, cooling stops reaction, neutralizes and filters, obtains small molecule glycol polyether dispersant;

[0042]3) 0.35% low-hydrogen silicone oil prepared by 50g step 1), 5.6g dodecene, 104.5g allyl alcohol polyether with a molecular weight of 1000 and 150g step 2) the small molecule ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap