Toilet bowl with simple flushing device and toilet bowl washing method

A toilet, simple technology, applied to flushing equipment with water tank, water supply device, sanitary equipment for toilets, etc. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

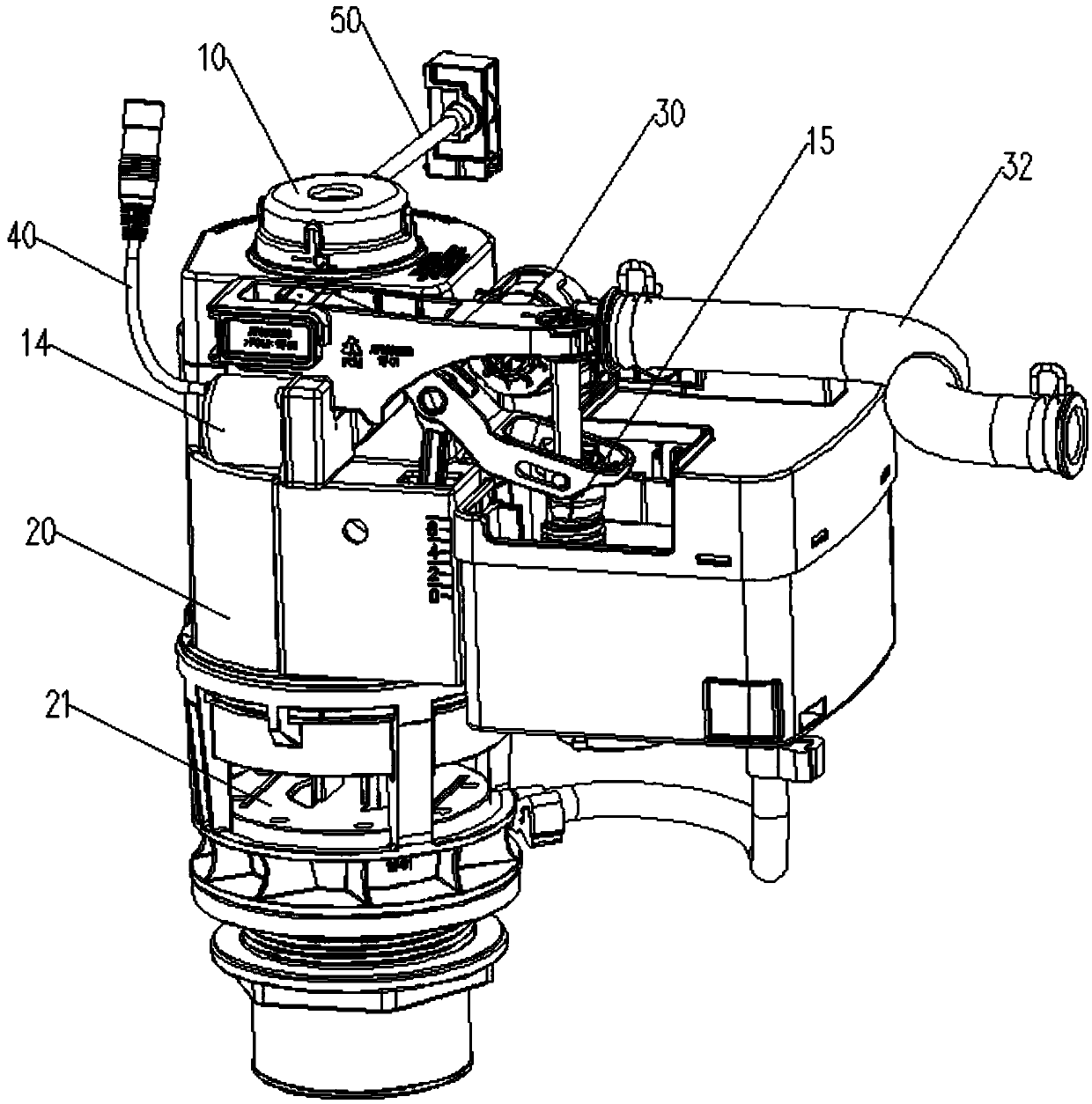

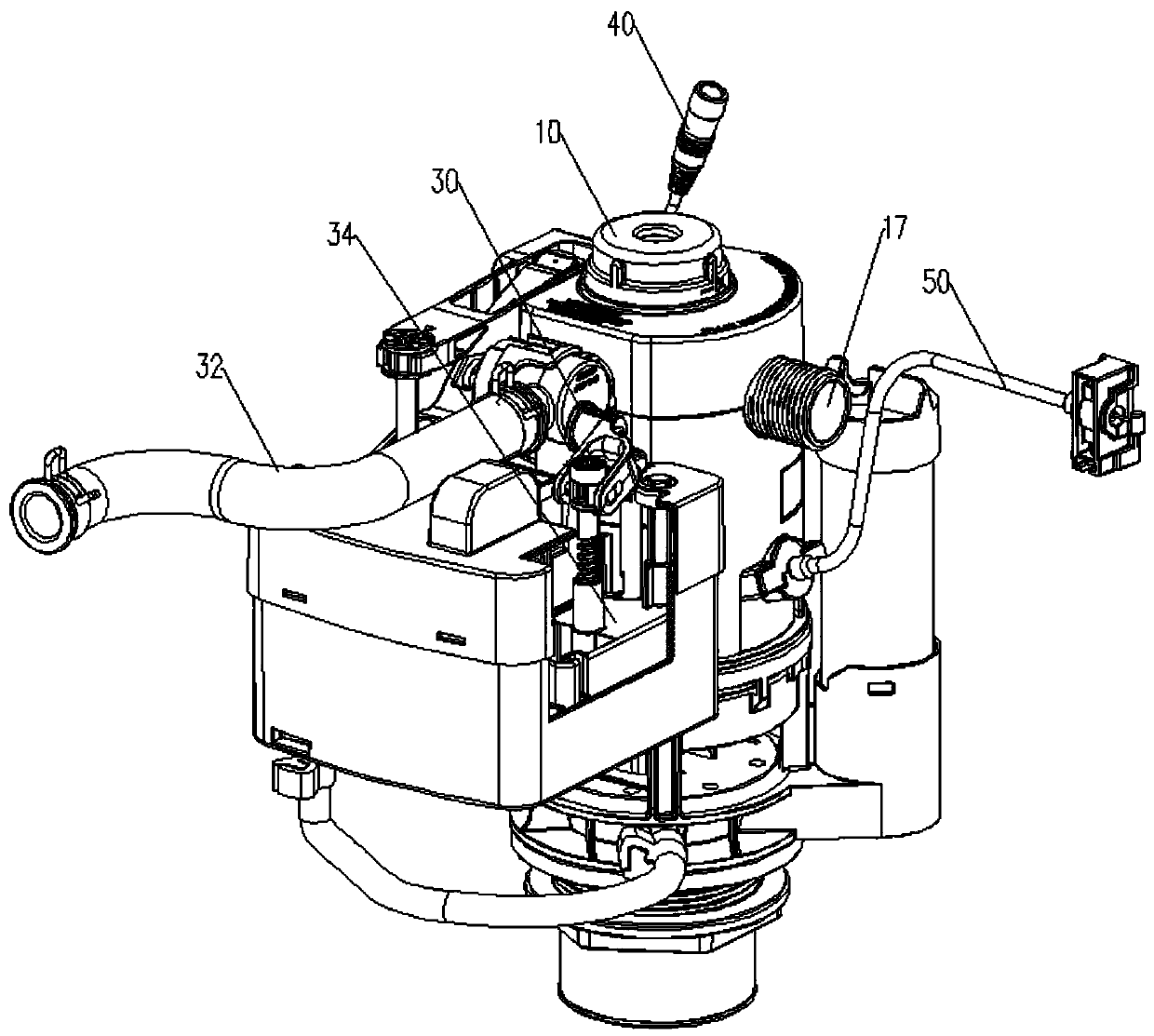

[0054] The first embodiment: (the water inlet mechanism and the drainage mechanism are integrally arranged)

[0055] Such as Figure 1 to Figure 11 As shown, a toilet with a simple flushing device, the toilet (not shown) includes a brush ring water channel (not shown) for flushing the inner wall of the urinal (not shown) and a main flush connected to the bottom of the urinal Waterways (not shown), also include:

[0056] A water tank (not shown) has a water tank cavity for storing flushing water, and the water tank is provided with a drainage channel (not shown) connecting the water tank cavity and the main flushing channel;

[0057] The water inlet mechanism 10 includes a water stop unit that opens or closes the water inlet mechanism 10, and the water stop unit includes a back pressure chamber (not shown in the figure) that is provided with a first pressure relief hole 12 and a second pressure relief hole 13 shown), when both the first pressure relief hole 12 and the second ...

no. 2 example

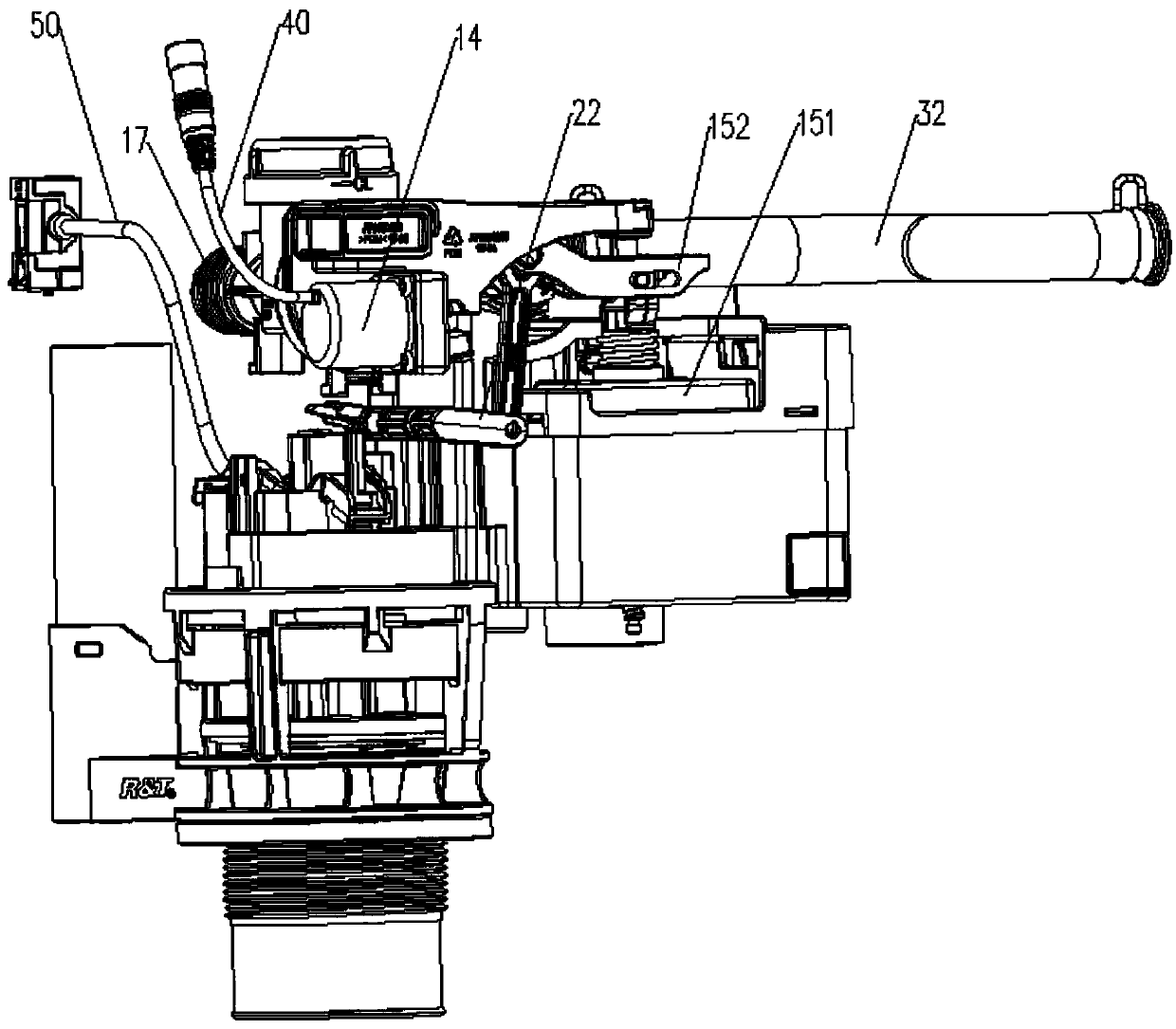

[0082] The second embodiment: (the water inlet mechanism and the drainage mechanism are independently arranged)

[0083] Such as Figure 12 to Figure 19 As shown, the difference between this embodiment and the above-mentioned embodiments is that the water inlet mechanism 10 and the water discharge mechanism adopt independent water inlet valves and water discharge valves, and there is no linkage between the floating bucket assembly 15 and the valve core 21, Such as Figure 18 and Figure 19 As shown, when the first starting unit 50 is started, the buoy bucket 151 opens the second pressure relief hole 13 as the water level in the inner cavity of the water tank drops to enable the water inlet mechanism 10 to start water intake, and the electronically controlled The component 14 controls the first pressure relief hole 12 to close before the second pressure relief hole 13 is closed, and the buoy 151 rises with the water level in the water tank to close the second pressure relief ...

no. 3 example

[0084] The third embodiment: (switching mechanism with injection function)

[0085] Such as Figure 20 to Figure 23 As shown, the difference between this embodiment and the first embodiment is that the switching mechanism 30 of this embodiment also includes a spray pipe 36 and a nozzle 35 communicating with the water outlet channel 11, and the nozzle 35 is connected to the spray pipe 36 The two ends of the spray pipe 36 are arranged at intervals, and the two ends of the spray pipe 36 are respectively connected with the water channel of the brush ring and the inner cavity of the water tank. , the switching member 31 is arranged on the spray pipe 36, so that the water outlet channel 11 is sprayed to the water channel of the brush ring or the inner cavity of the water tank through the nozzle 35. This structure is a prior art and will not be repeated here.

[0086] The present invention also proposes a toilet flushing method using the toilet with a simple flushing device in any o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com