Electronic control ammonia injection system

An electronically controlled injection and ammonia technology, which is applied to the electronic control, exhaust treatment, and exhaust devices of exhaust gas treatment devices, can solve the influence of quantitative injection of ammonia gas, unstable flow rate, and difficulty in matching the amount of ammonia gas with exhaust gas. The need for purification, etc.

Pending Publication Date: 2018-12-28

科林蓝泰环境科技(长春)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the basis of this design, there are still some problems in how to put the ammonia gas stored in the storage tank into use efficiently and accurately, especially because the ammonia storage tank releases ammonia gas at different rates in different environments, resulting in the output flow rate of Unstable, which affects the quantitative injection of ammonia gas later, and the amount of ammonia gas injected is difficult to match the demand for exhaust gas purification

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

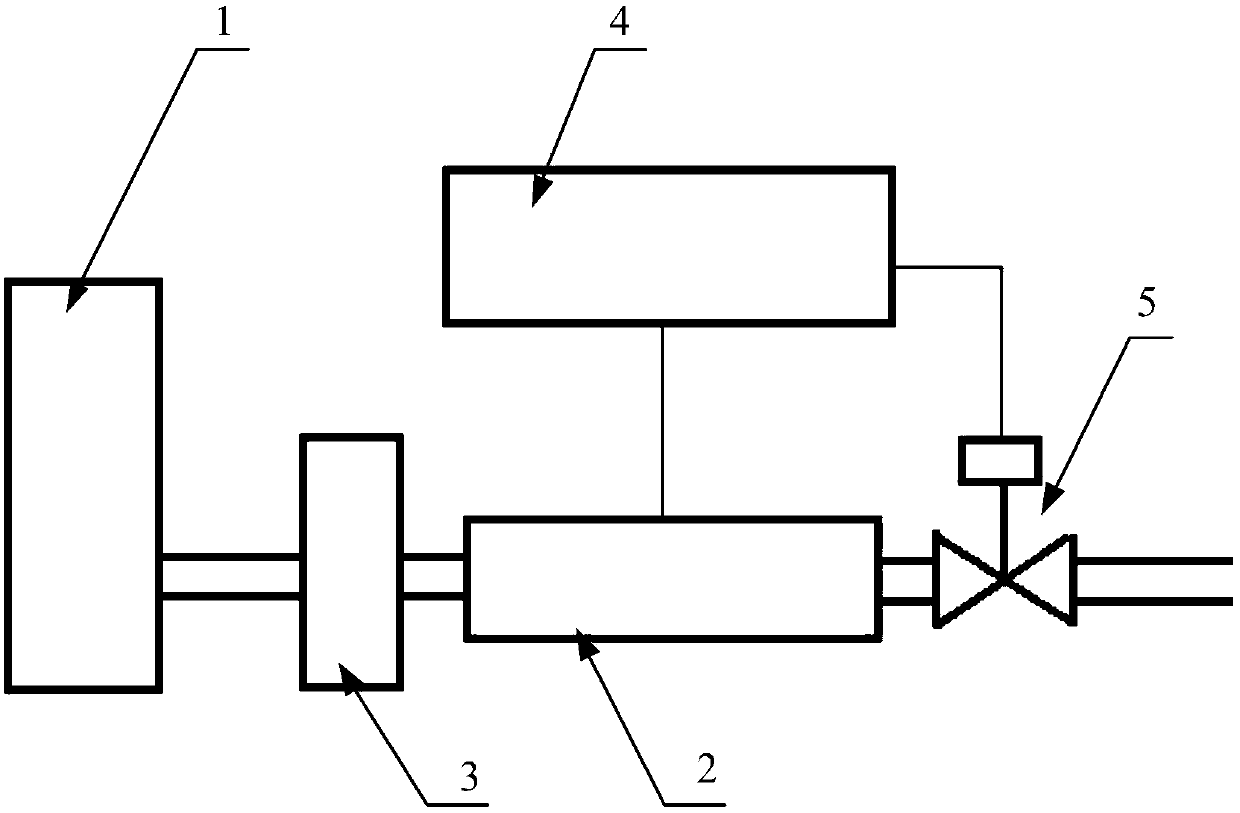

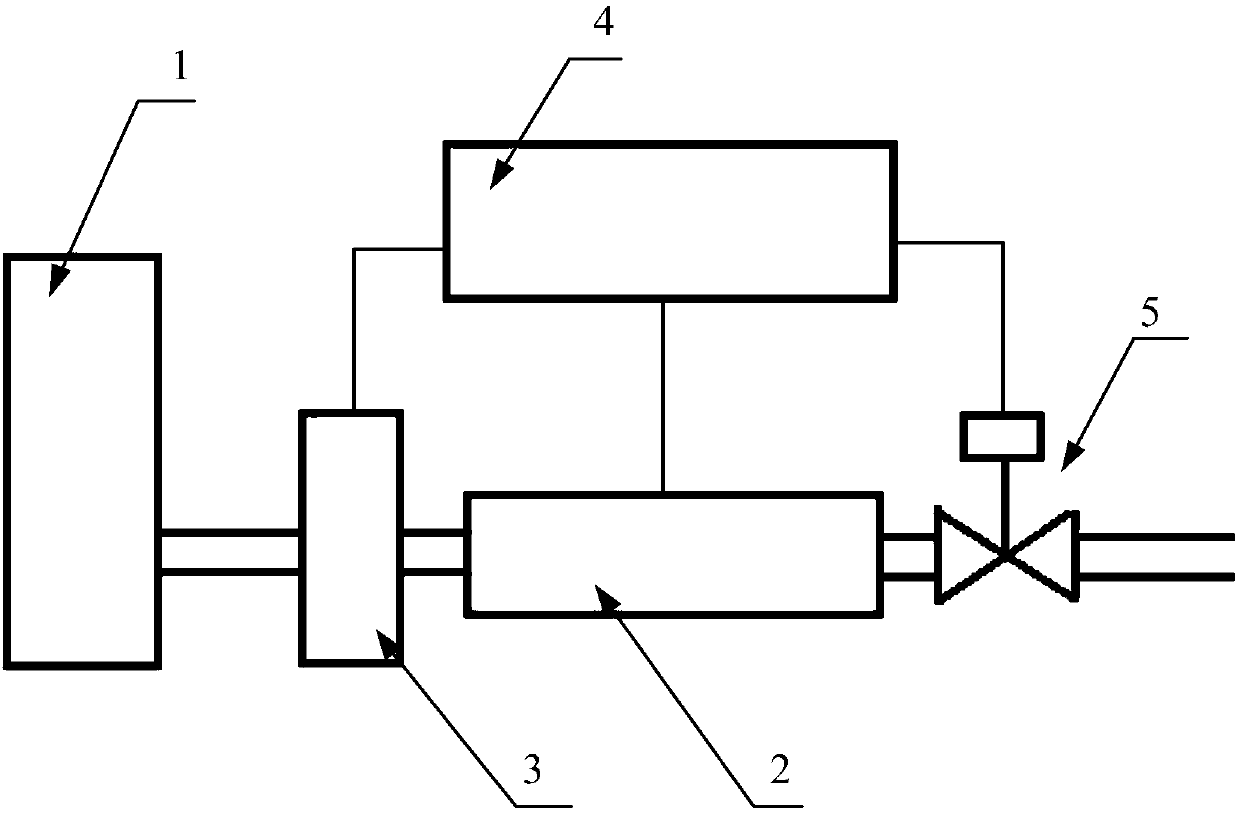

The invention discloses an electronic control ammonia injection system. The electronic control ammonia injection system comprises an ammonia storage tank, a flow collecting device and a pressure regulating valve, wherein the ammonia storage tank is used for storing and releasing ammonia, the flow collecting device is communicated with the ammonia storage tank and an ammonia output pipe for metering throughput of ammonia; the pressure regulating valve is arranged on the pipe between the ammonia storage tank and the flow collecting device for controlling the output pressure of the ammonia storage tank. The output pipe of the ammonia storage tank is provided with the flow collecting device to acquire of the jet flow of ammonia, thereby achieving the aim of precise output; the output end of the ammonia storage tank is provided with the structure of the pressure regulating valve to control the output pressure of the ammonia storage tank within a preset range, thereby achieving the effect ofstable output, effectively ensuring precise control and measurement of the ammonia output of the subsequent output process, ensuring that the output ammonia can meet the practical demands of exhaustpurification and avoiding waste leakage or incomplete purification.

Description

technical field The invention relates to the technical field of automobile tail gas purification, in particular to an ammonia electronically controlled injection system. Background technique The exhaust gas treatment device of the automobile is mainly a device that purifies the exhaust gas under the action of the catalyst to reduce the pollution to the environment. Automobile exhaust is the exhaust gas produced by the use of automobiles. It contains hundreds of different compounds. The pollutants include solid suspended particles, carbon monoxide, carbon dioxide, hydrocarbons, nitrogen oxides, lead and sulfur oxides. At present, the mainstream exhaust gas purification equipment is realized by catalyst. When high-temperature automobile exhaust gas passes through the purification device, the purifier in the catalyst will enhance the activity of CO, HC and NOx gases, and promote certain redox chemical reactions. In order to change the harmful gas into a harmless gas, so that ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F01N3/20F01N9/00

CPCF01N3/2066F01N3/208F01N9/00F01N2610/02F01N2610/146Y02T10/40

Inventor 郝赫

Owner 科林蓝泰环境科技(长春)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com