Novel rotary pressure pulse controller and operation method

A pressure pulse and controller technology, applied in the field of new rotary pressure pulse controllers, can solve the problems of large spool reversing switching noise, large spool loss, large comprehensive control error, etc., and achieves reduced operating noise and sensitive adjustment performance. , the effect of wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0014] The invention provides a novel rotary pressure pulse controller and working method, which has the advantages of simple structure, high integration, low operating noise, wide pressure pulse adjustment range, sensitive adjustment performance, no movement stop limiting parts in the valve body, and low operating loss.

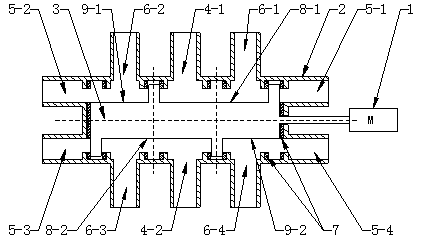

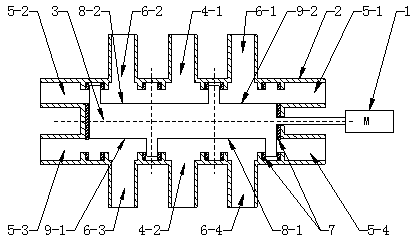

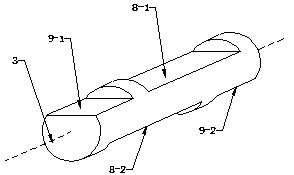

[0015] Such as figure 1 , figure 2 and image 3 As shown, a new rotary pressure pulse controller described in the present invention includes a frequency conversion control motor 1, a controller housing 2, a rotating shaft core 3, a high-pressure oil supply interface A4-1, and a high-pressure oil supply interface B4-2 , Low pressure relief port A5-1, Low pressure relief port B5-2, Low pressure relief port C5-3, Low pressure relief port D5-4, Test piece port A6-1, Test piece port B6-2, Test piece port C6-3, test piece interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com