Rubber hose for automobile

A technology of rubber hose and hose, which is applied in the field of auto parts, can solve the problems of not having the function of long service life, and achieve the effects of avoiding deformation, improving service life and improving practicability

Pending Publication Date: 2018-12-28

泉州嘉宸科技有限公司

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a rubber hose for automobiles, which has the advantage of long service life, and solves the problem that rubber hoses for automobiles in the existing market do not have the function of long service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

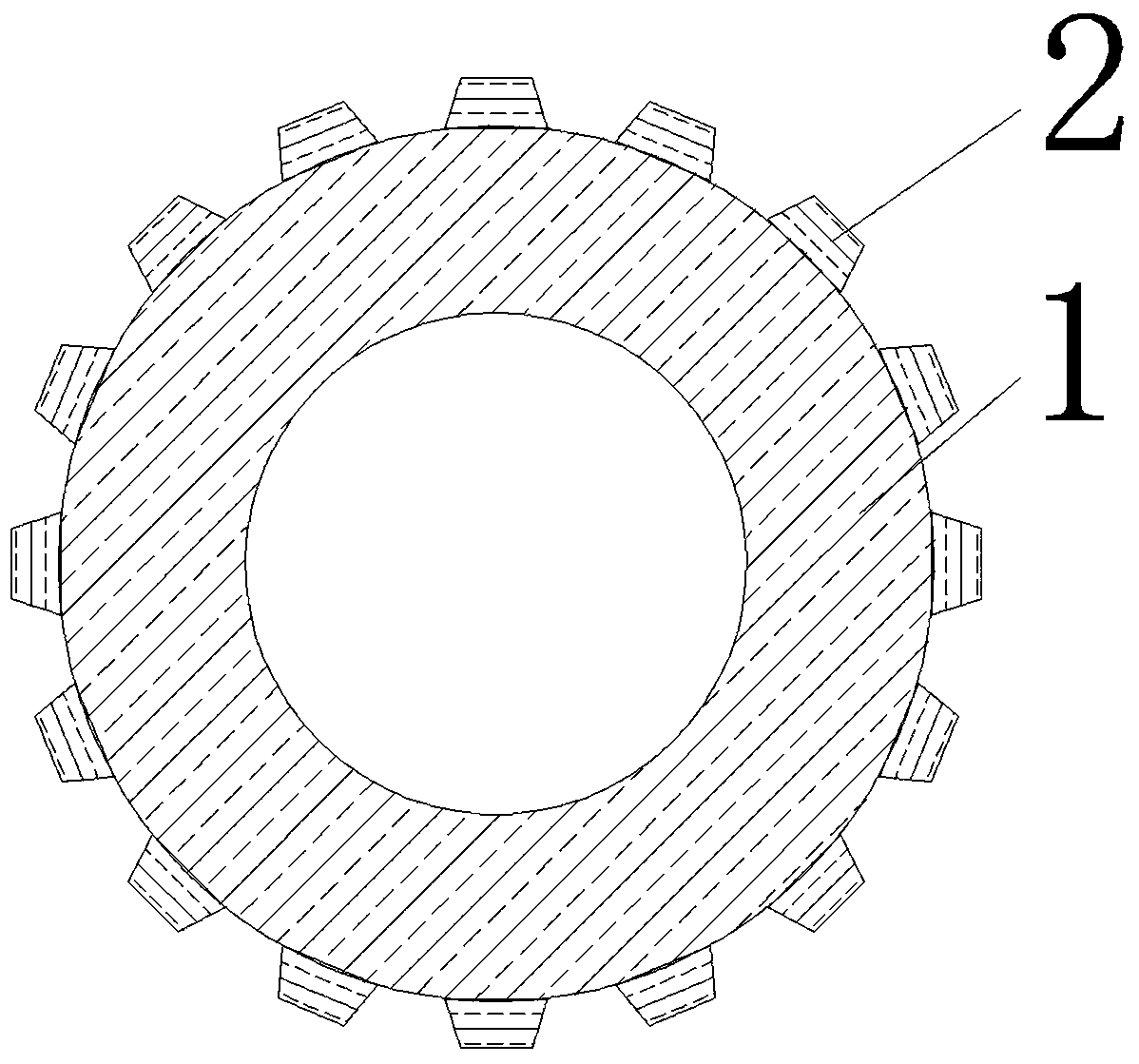

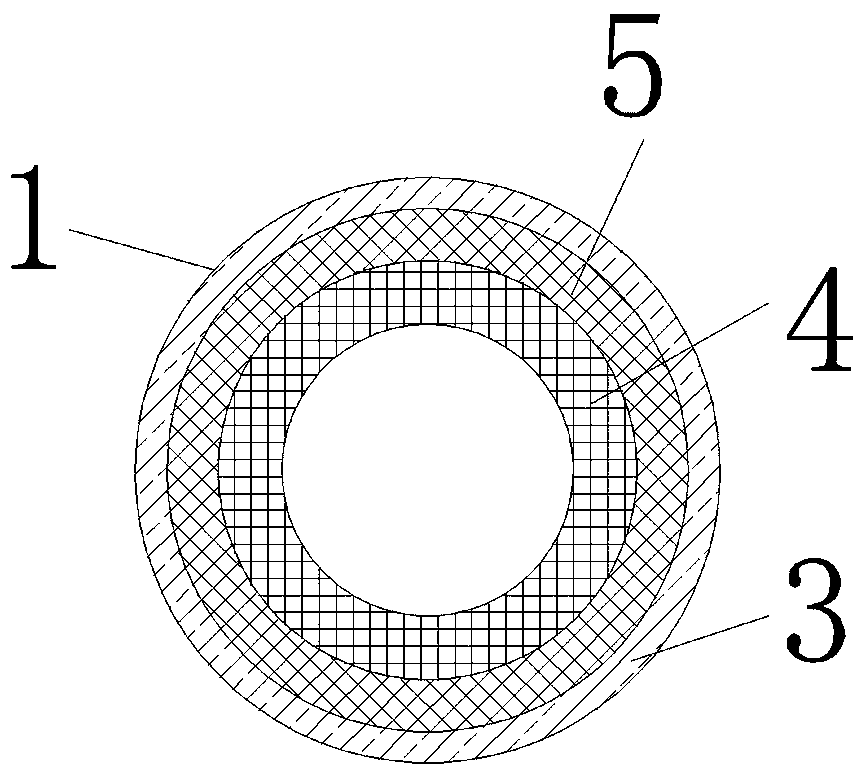

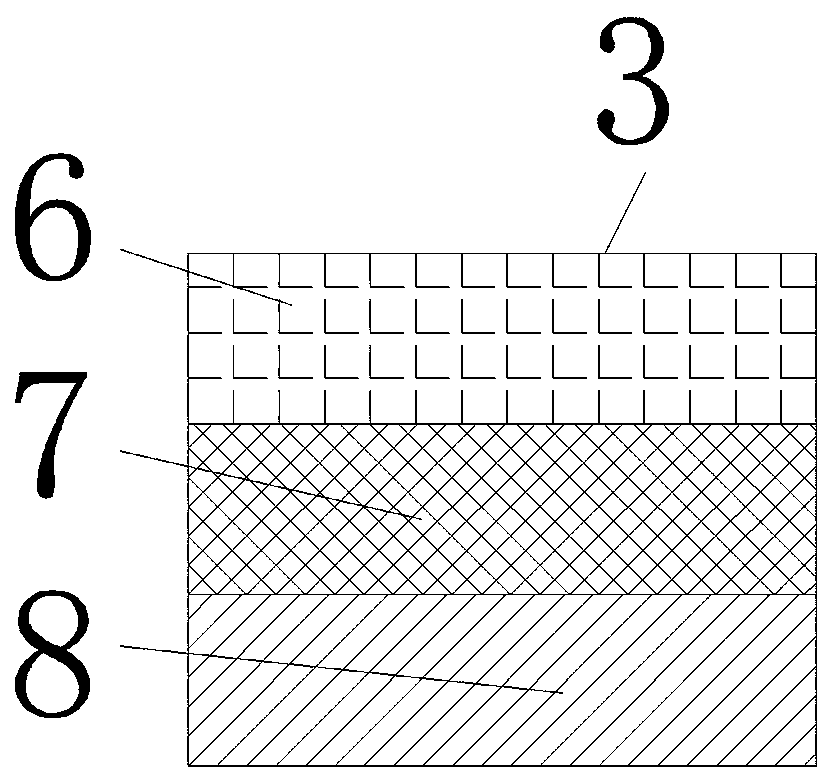

The invention discloses a rubber hose for an automobile. The rubber hose comprises a hose body which comprises a wear-resistant layer, a high-temperature-resistant layer and a hose base layer, the hose base layer is arranged in an inner cavity of the wear-resistant layer, the high-temperature-resistant layer is arranged in an inner cavity of the hose base layer, and the wear-resistant layer comprises a graphene layer, a polyurethane wear-resistant layer and a butadiene rubber layer. By arranging a wear-resistant boss, a graphene coating, the polyurethane wear-resistant layer, the butadiene rubber layer, a polyimide layer, an alumina coating, a graphite coating and a steel wire reinforced layer, the rubber hose has long service life, and the problems that rubber hoses on existing market donot have long service life, automobile engines shake seriously when working as the hoses deform at high temperature for a long time due to the fact that braking hydraulic oil is high in temperature when in use and driving safety is adversely affected as the hoses are quite short in service life due to the fact that the hoses shake seriously when in use, thereby being prone to wear are solved.

Description

Technical field The invention relates to the technical field of automobile parts, in particular to a rubber hose for automobiles. Background technique In the production of automobile hoses, rubber materials are widely used due to their good heat resistance, oil resistance and ozone resistance. The radiator hose is connected between the car’s engine and the radiator to transport the coolant to ensure the engine’s The function of normal work, the hose of the engine radiator will age and easily break after long-term use, and the society has stricter requirements on the automobile, forcing the automobile radiator hose to continuously improve heat resistance, cold resistance, oil resistance, aging resistance, etc. Performance to improve the safety of car users. The various parts of the automobile need to use rubber hoses for connection, especially the connection between the oil circuits must use hoses for oil transfer. The existing rubber hoses on the market do not have the functio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L11/10

CPCF16L11/10

Inventor 刘琼阳

Owner 泉州嘉宸科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com