Elliptical arc plus circular arc head and molding die of elliptical arc plus circular arc head

A technology of forming molds and elliptical arcs, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient manufacturing and high consumption of materials, and achieve the effect of good stress state and less material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

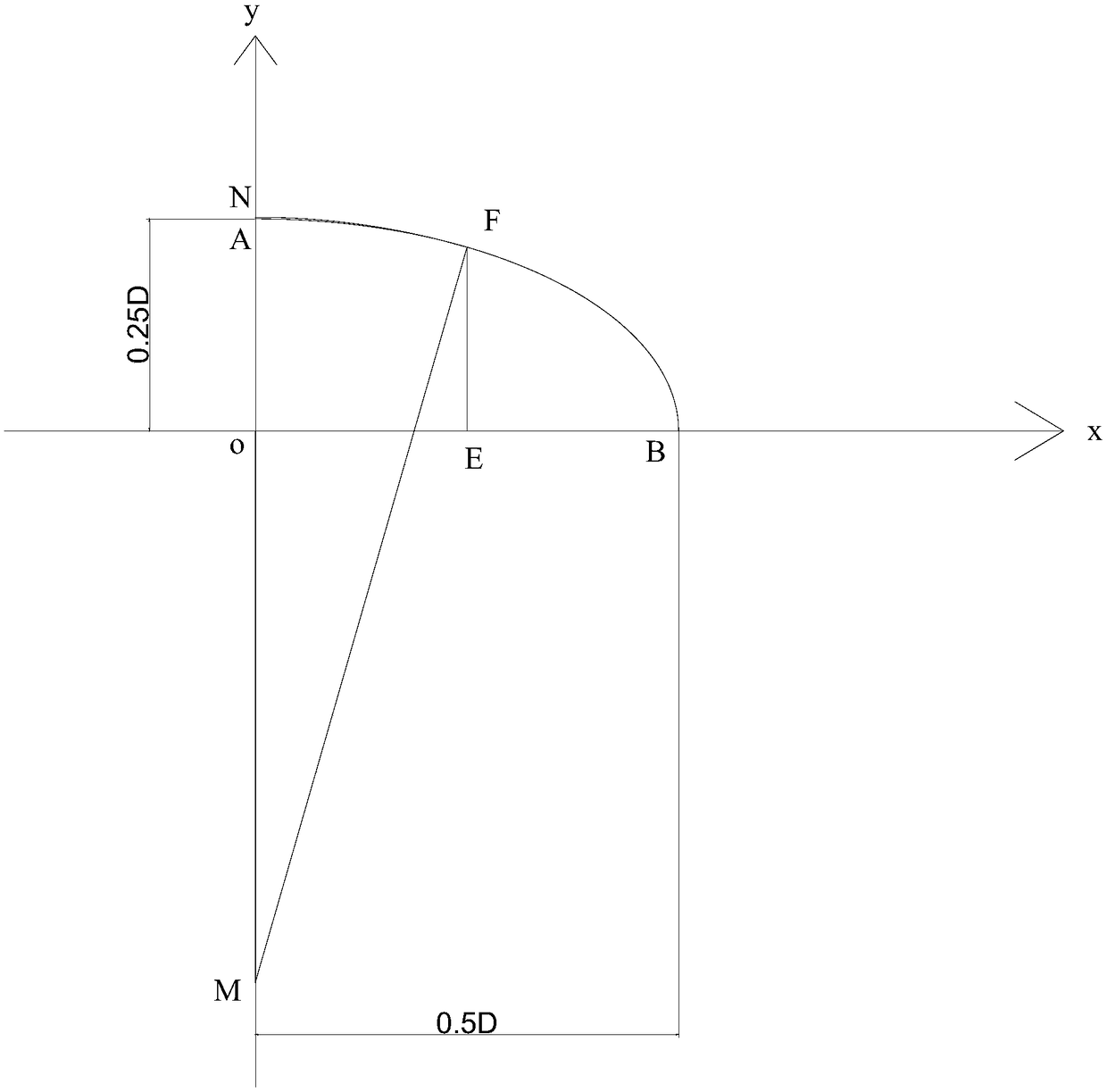

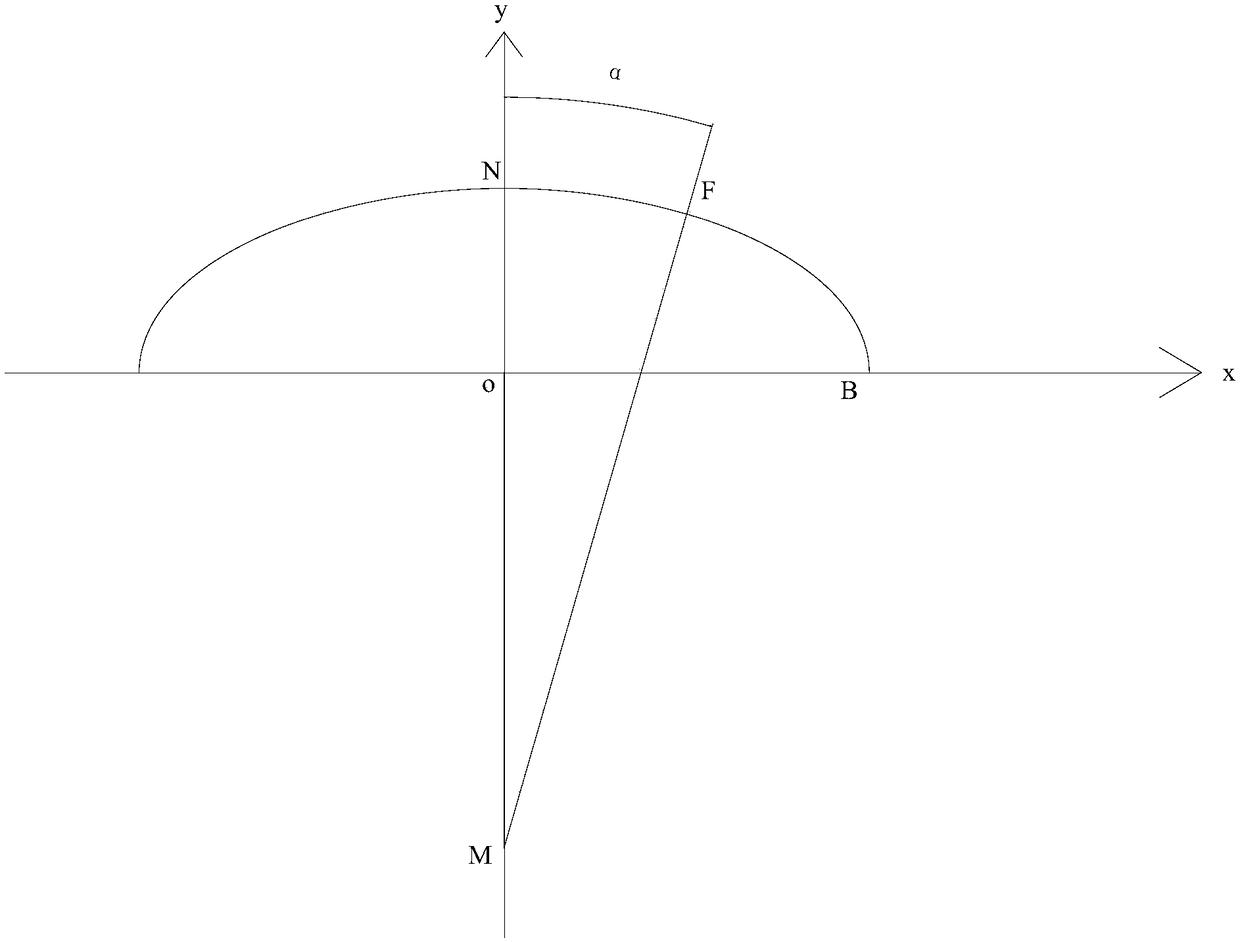

Embodiment 1

[0040] This embodiment provides an elliptical arc plus circular arc type head. The inner surface of the elliptical arc plus circular arc type head is regarded as the middle surface, and the middle surface is formed by rotating the meridian with the preset axis Y as the rotation axis. The meridian includes The transition section is an elliptical arc section and the middle section is a circular arc section, and the elliptical arc section and the circular arc section have a smooth transition. That is, the normal or tangent of the intersection point at the intersection of the two arcs coincides. In production practice, the difference between the inner surface and the middle surface of the head is generally ignored. Compared with the common standard oval head (referred to as the standard oval head) and the standard disc-shaped head (referred to as the standard disc head), this kind of elliptical arc and arc-shaped head has a better stress state. Consumes less material and is more ...

example 1

[0062] Example 1 Design condition: P c =0.9MPa, t=-196°C, D i =2100mm,

[0063] [σ] t =137Mpa, φ=1.0, material S30408, the δ of the standard oval head is 6.9mm, and the δ of the elliptical arc plus arc type head is 6.2mm. If the thickness addition is 0.8mm, the nominal thickness is 8mm, so the blanking thickness can be 10mm and 8mm respectively, and the minimum thickness after forming is 6.9mm and 6.2mm respectively. Their masses are 395.1Kg and 315.3Kg respectively. The latter accounts for about 80% of the former.

example 2

[0064] Example 2 Design condition: P c =1.6MPa, t=50℃, D i =3400mm, [σ] t =185Mpa, φ=1.0, material Q345R, then the δ of the standard elliptical head is 14.7mm, and the δ of the elliptical arc plus arc type head is 13.3mm. If the thickness addition is 2.3mm, the nominal thicknesses are 18mm and 16mm respectively, so the blanking thicknesses can be 20mm and 18mm respectively, and the minimum thicknesses after forming are 16.2mm and 14.8mm respectively. Their masses are 1996.1Kg and 1793.9Kg respectively. The latter accounts for about 90% of the former.

[0065] Example 3 Design condition: P c =2.8MPa, t=80℃, D i =2200mm, [σ] t =137Mpa, φ=1.0, material S30408, the δ of the standard elliptical head is 22.6mm, and the δ of the elliptical arc plus arc type head is 20.3mm. If the thickness addition is 0.8mm, the nominal thicknesses are 24mm and 22mm respectively, so the blanking thicknesses can be 26mm and 24mm respectively, and the minimum thicknesses after forming are 22.6mm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap