Calculation method of resistance loss of paste filling slurry pipeline transportation based on T-H coupling

A paste filling and pipeline conveying technology, applied in the field of paste filling, can solve problems such as the influence of the accuracy of simulation results, and achieve the effect of reducing industrial test time and optimizing rheological parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

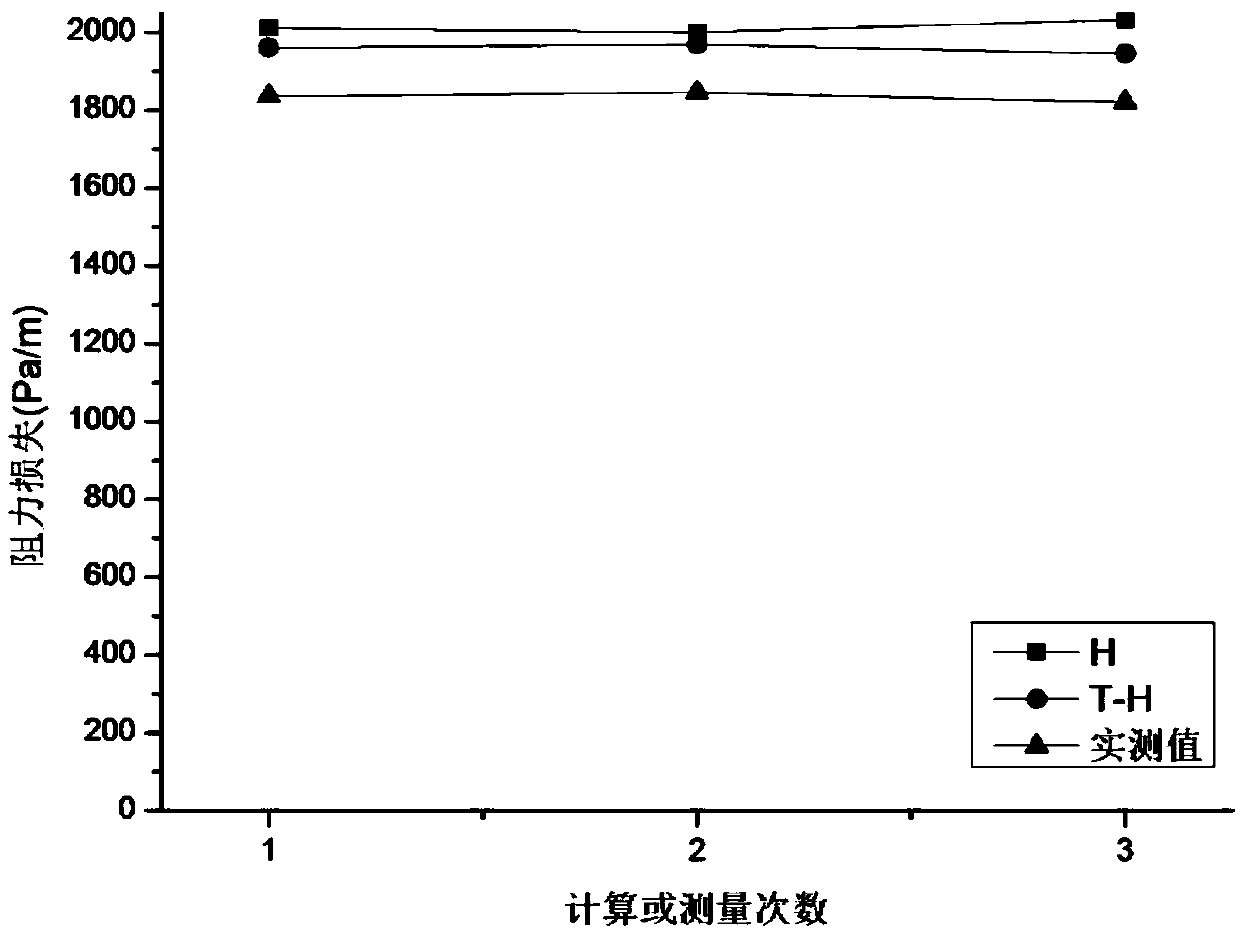

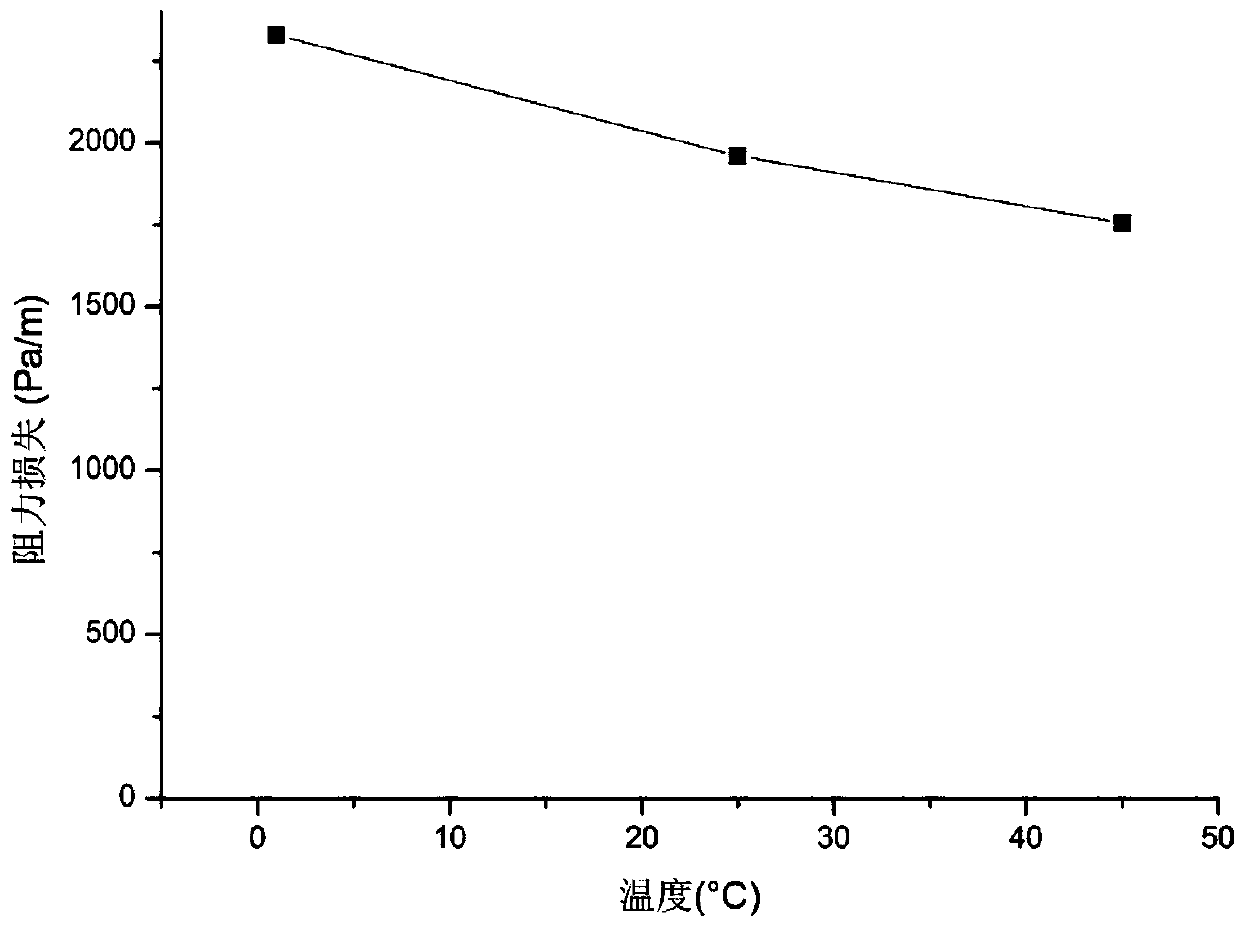

[0057] Such as Figure 1-4 As shown, the present invention aims to provide a pipeline transportation simulation method of paste filling slurry under the coupled action of temperature and fluid mechanics, and the simulation method can systematically obtain the pipeline transportation characteristics of paste filling slurry during the process of temperature influence.

[0058] Treat the paste filling slurry as a homogeneous fluid, couple its flow field and temperature field, use the Euler method to describe the fluid flow, use the differential equation of fluid heat transfer to describe the role of the temperature field, and couple the thermal stress to the fluid flow In the stress balance differential equation, the T-H coupling mathematical model is formed, and the parameters measured by the rheometer are further optimized, so as to q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com