A dual-stator claw-pole axial flux permanent magnet vernier motor

A technology of axial flux and vernier motor, which is applied in the direction of magnetic circuit, electric components, electrical components, etc., can solve the problems of inflexible axial size and insufficient research of double stator axial flux permanent magnet vernier motor, etc., to achieve Excellent engineering performance, high utilization rate of permanent magnets, and low torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

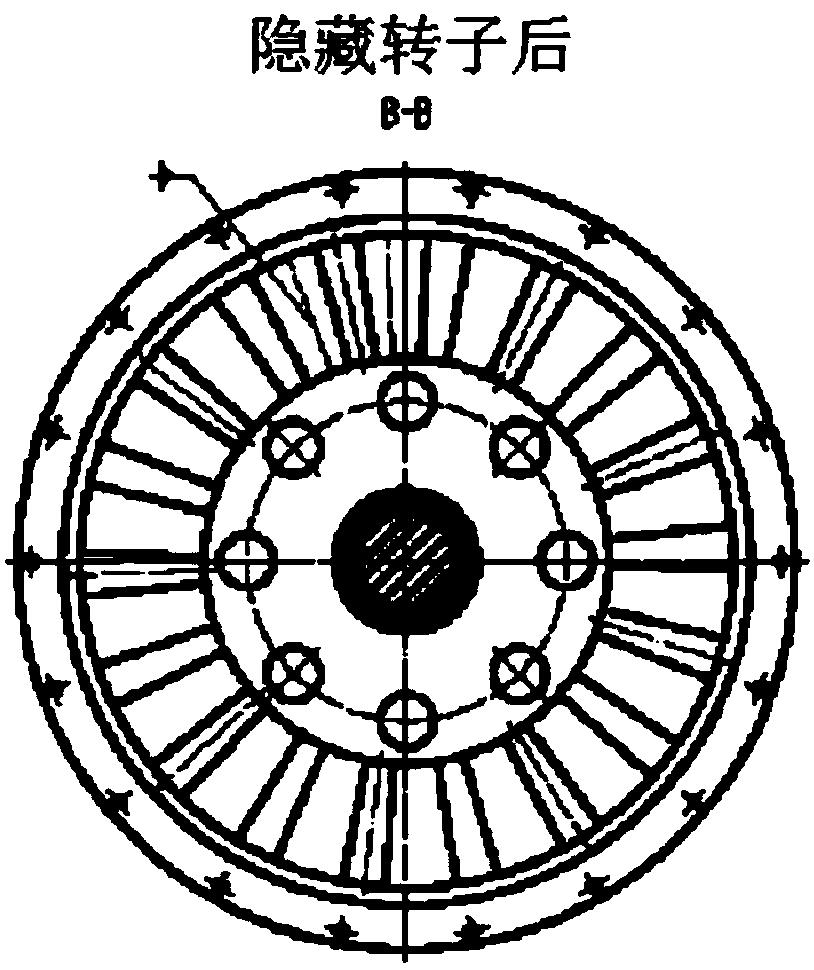

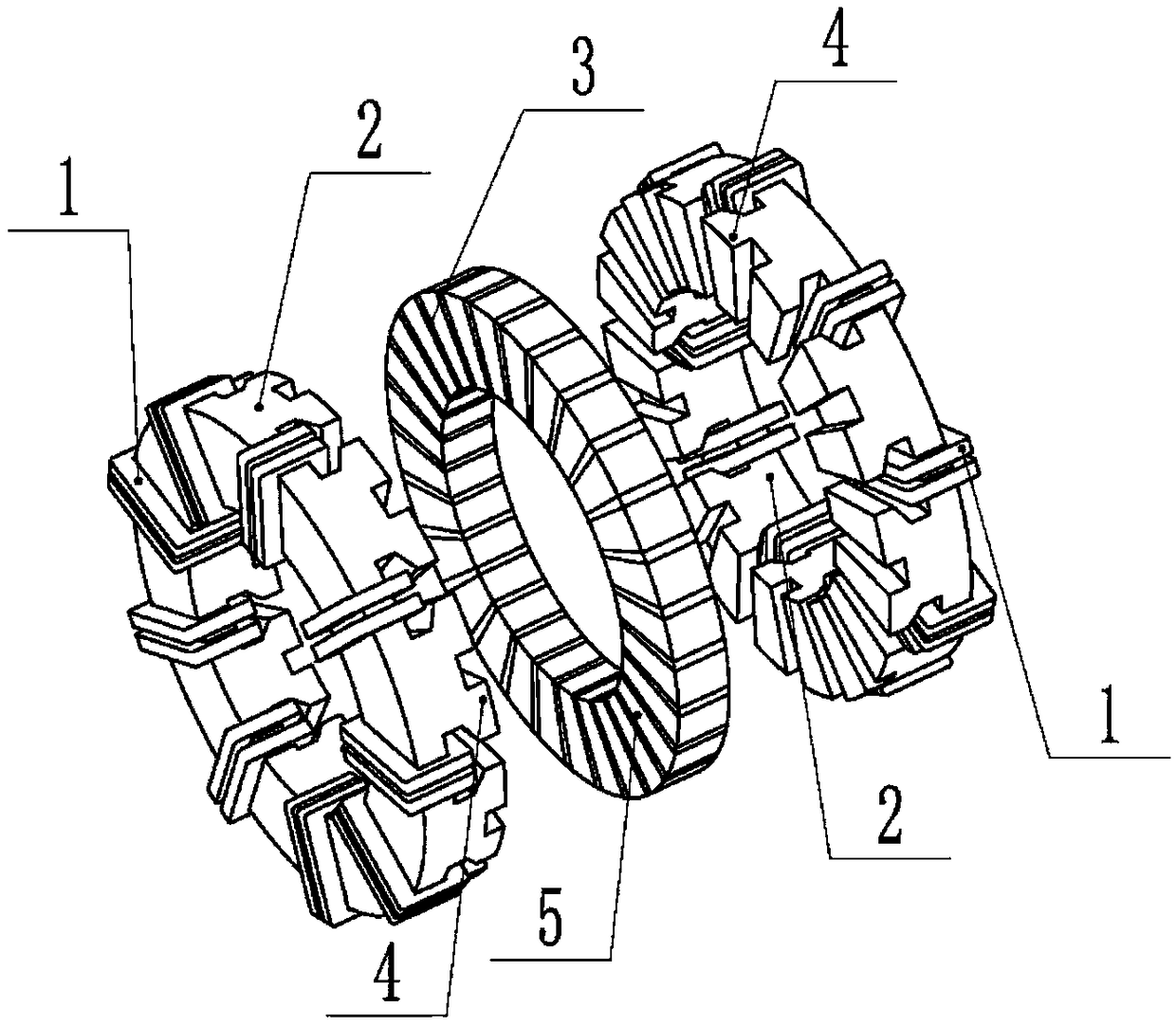

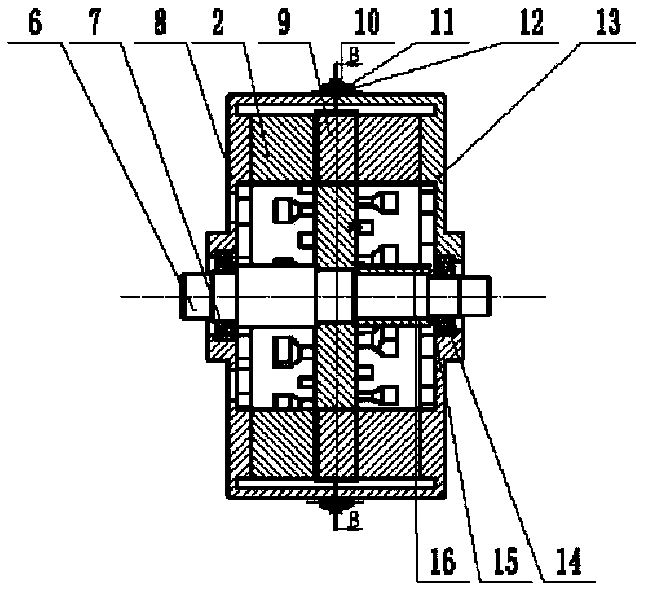

[0031] Such as Figure 1-5 As shown, this embodiment provides a dual-stator claw-pole axial flux permanent magnet vernier motor, including a transmission shaft 6, a motor housing, an outer stator 2, a rotor 9, an outer stator 2, an outer stator 2, and a rotor 9. The outer stators 2 are arranged in sequence in the axial direction. The structures of the two outer stators 2 are the same. Both outer stators are equipped with claw-type modulation teeth 4. Three-phase windings 1 are wound on the stator slots. The claws on the two outer stators The pole modulating teeth are set opposite to each other, and there is an air gap between both sides of the rotor and the two outer stators, and the air gap between the rotor 9 and the two outer stators 2 is between 1mm-2mm, preferably 1.5mm. A rotor permanent magnet is arranged on the rotor, and the modulating teeth of the two outer stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com