Structural integration in situ driving full displacement composite amplified piezoelectric linear stage

A compound amplification, electric inchworm technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of reducing platform life, low platform motion speed, and motion stability. Reduce and other problems, to achieve the effect of reducing the requirements of processing and assembly accuracy, the platform structure is compact, and the stability is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

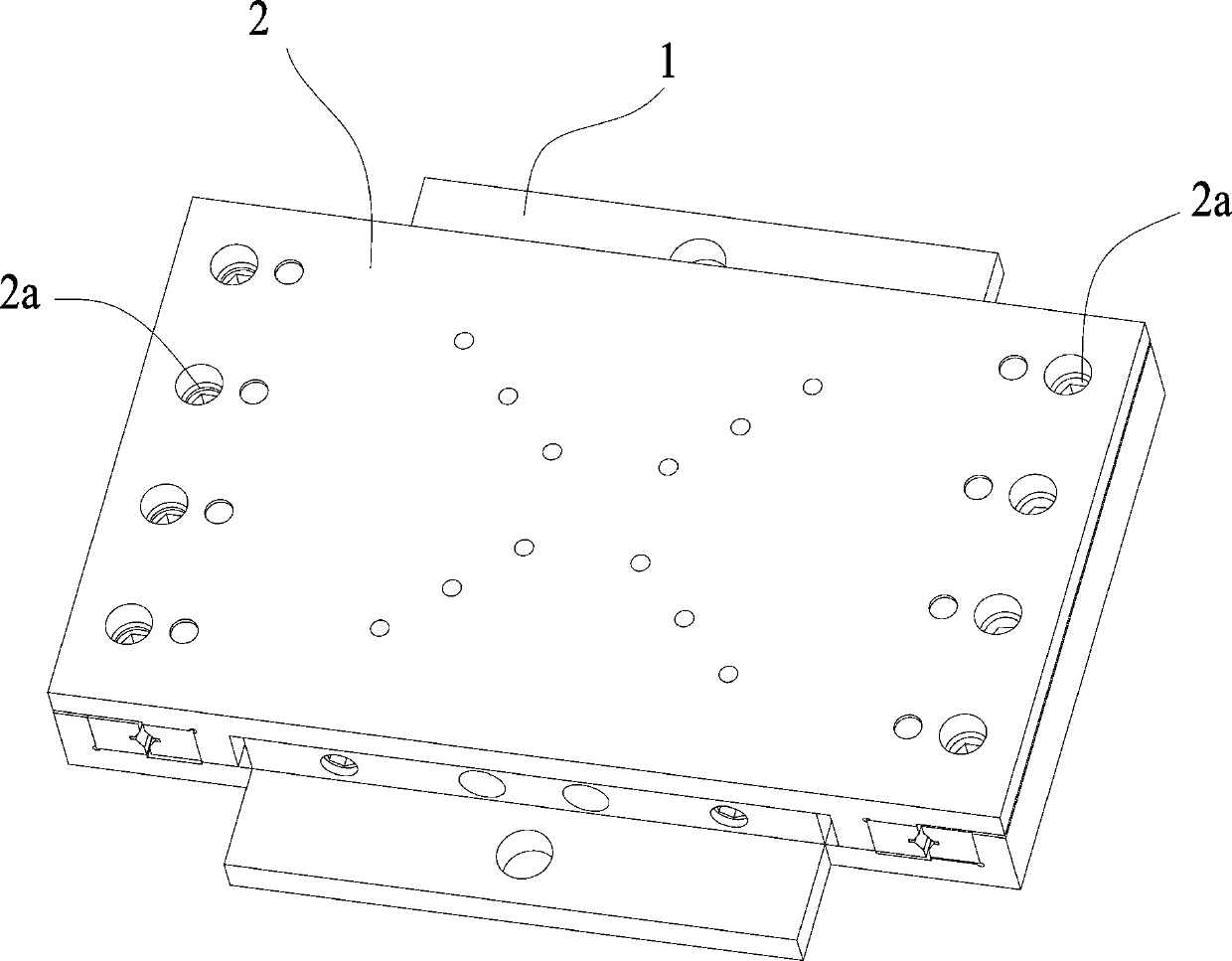

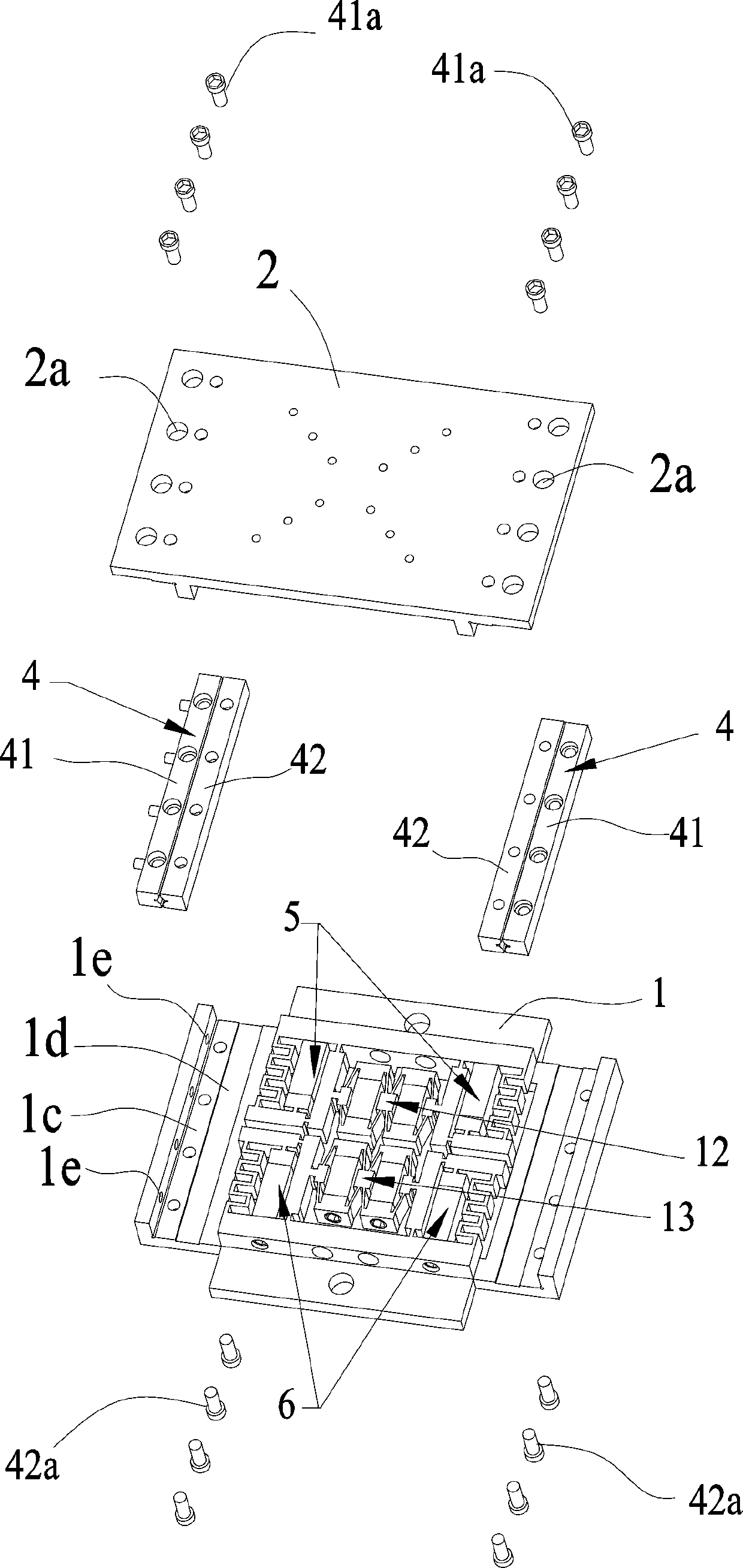

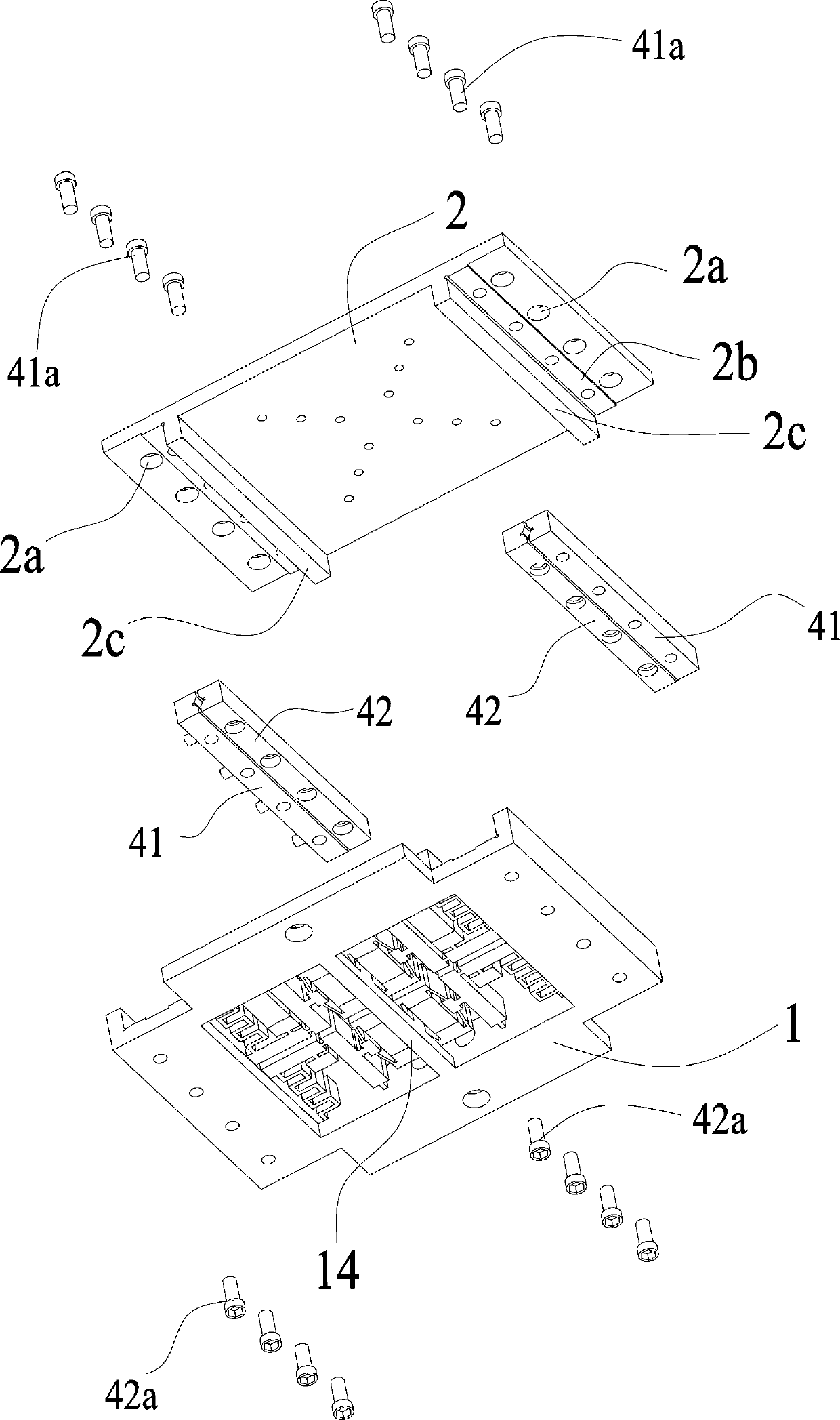

[0042] Figure 1 to Figure 7 It is a schematic diagram of the structure of the present invention, as shown in the figure, the structurally integrated in-situ drive full-displacement composite amplified piezoelectric inchworm linear platform of the present invention includes a fixed platform 1 and a moving table that is slidably connected by two cross roller guide rails 4 2. There are two retaining bars 2c parallel to the cross roller guide rail 4 under the moving table 2; the first clamping group 12 and the second clamping group 12 arranged along the length direction of the retaining bars 2c are arranged between the two retaining bars 2c. The clamping group 13, the first clamping group 12 and the second clamping group 13 perform telescopic movement along the direction perpendicular to the bar 2c, and their telescopic ends are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com