Garden engineering garbage treatment device and realization method thereof

A garbage disposal device and garbage disposal technology, applied in grain processing, garbage storage, manufacturing tools, etc., can solve the problems of increasing weight, prone to tail flicking, and affecting the service life of the machine, so as to achieve good transportation, avoid tail flicking and The effect of violent vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

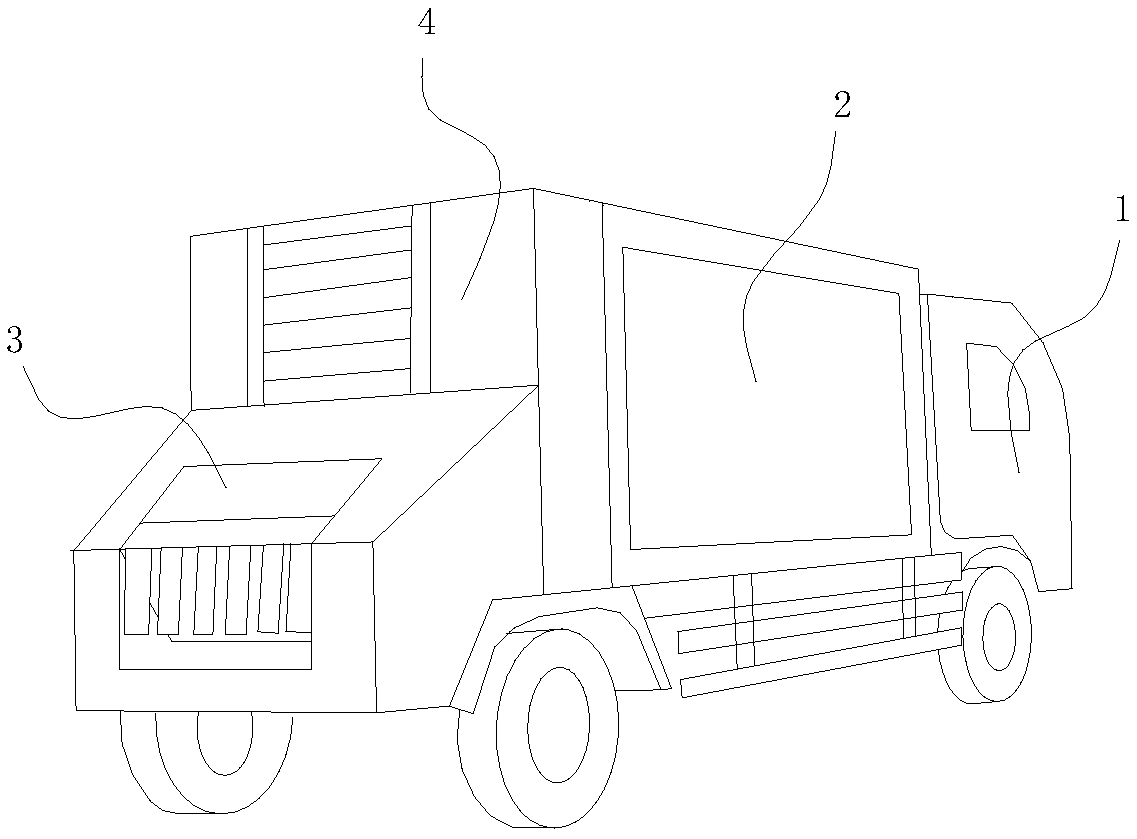

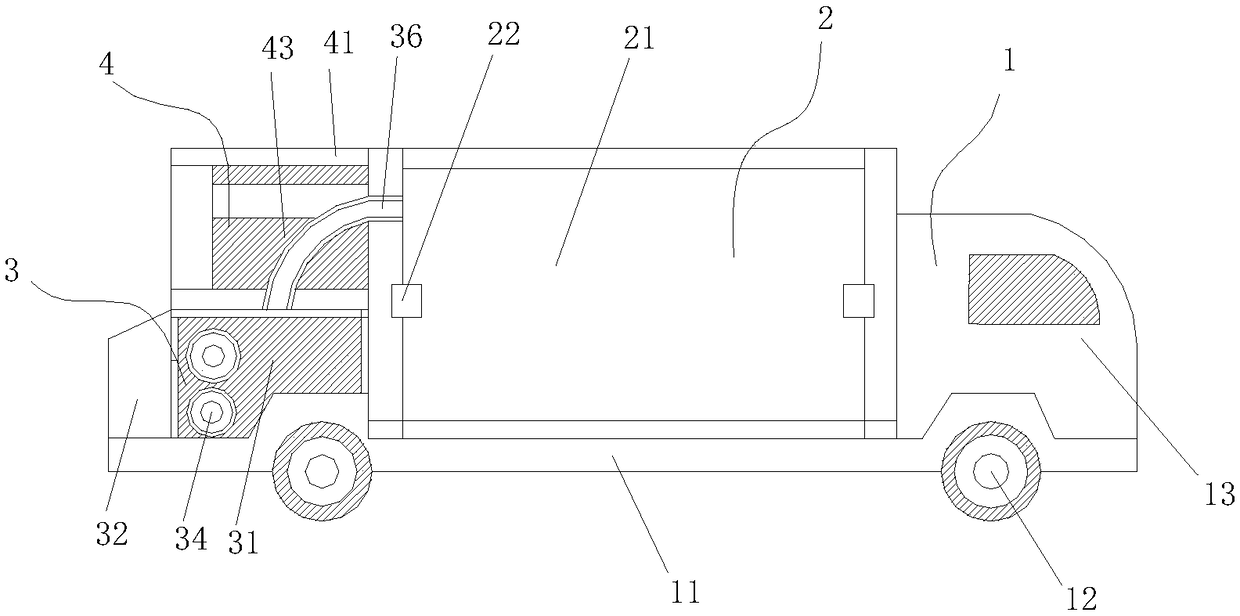

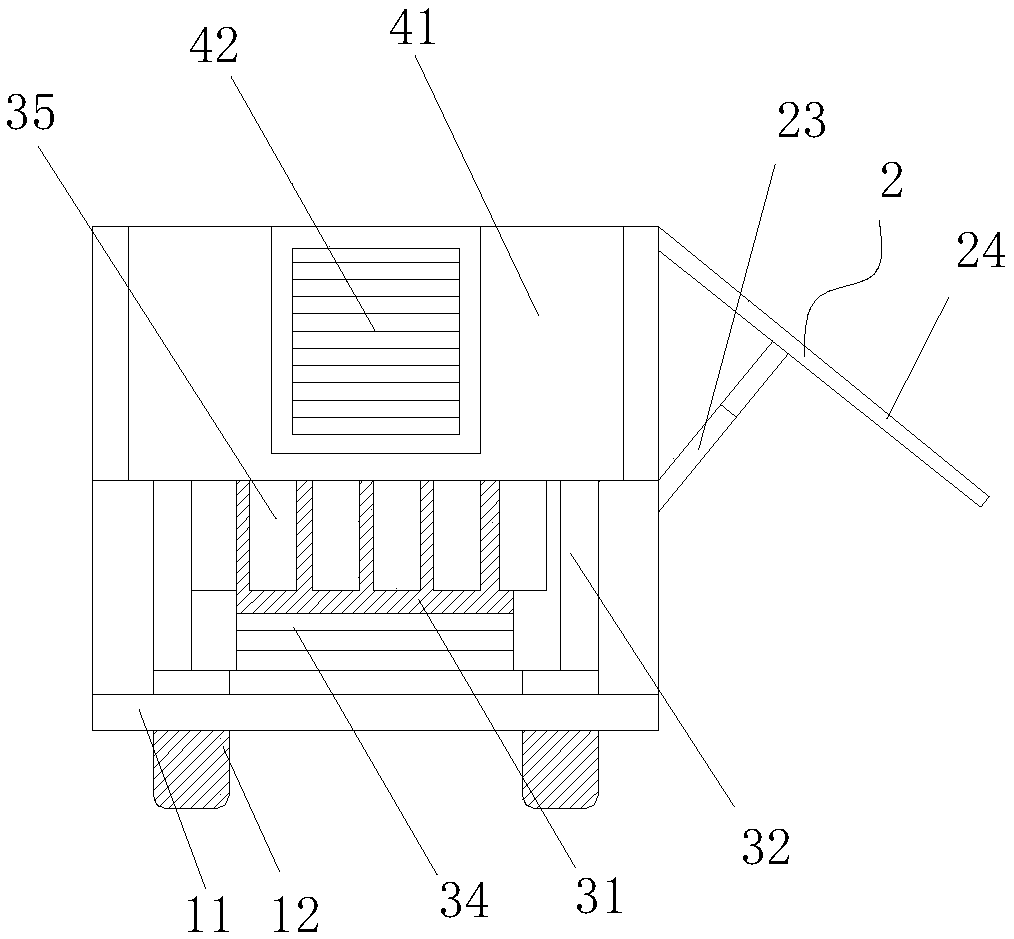

[0027] see Figure 1-4 , the present invention provides the following technical solutions: a garden engineering waste disposal device, comprising a garden engineering waste disposal vehicle body 1, a sawdust storage box 2 is welded on the garden engineering waste disposal vehicle body 1, and the sawdust storage box 2 includes a box body 21 and a box The door 24, wherein the box body 21 and the box door 24 are connected by rotating shafts, and one side of the sawdust storage box 2 is respectively welded with a crushing assembly 3 and a power output assembly 4, wherein the power output assembly 4 is fixedly connected to the upper end of the crushing assembly 3 by screws .

[0028] Further, the garden engineering garbage disposal vehicle body 1 includes a chassis 11, wheels 12 and a headstock 13, wherein the lower end of the chassis 11 is rotatably connected with four wheels 12 through rotating shafts and bearings, and the upper end of the chassis 11 is connected and fixed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com