All-in-one system based on spray coating and roller coating

An all-in-one machine and roller coater technology, which is applied to the surface coating liquid device, coating, spray booth, etc., can solve the problem of high production cost, achieve the effect of continuous material supply and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The all-in-one machine system based on spraying and roller coating of the present invention will be described in more detail below in conjunction with schematic diagrams, wherein a preferred embodiment of the present invention is represented, and it should be understood that those skilled in the art can modify the present invention described here, and still realize Advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

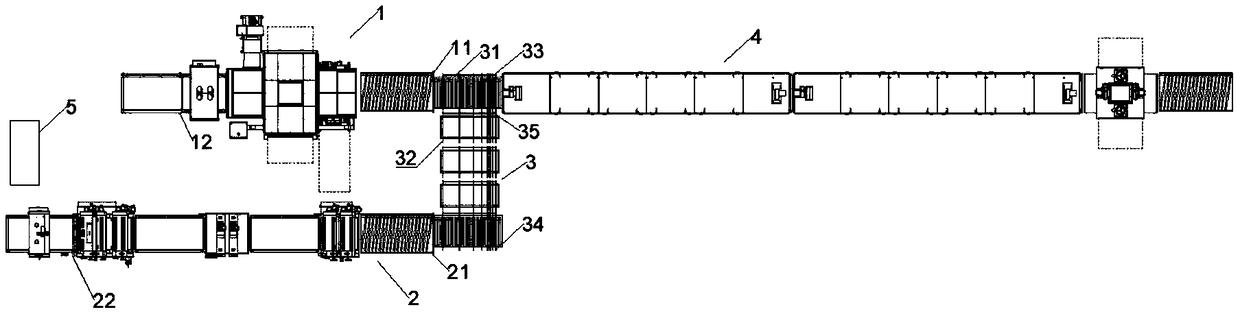

[0029] Such as figure 1 As shown, an all-in-one system based on spraying and roller coating includes automatic roller coating machine 2, automatic spraying machine 1, horizontal feeder 3, thermal dryer 4 and control unit 5; automatic spraying machine 1 and thermal drying The machine 4 is arranged on both sides of the horizontal feeder 3; the automatic roller coater 2 and the automatic sprayer 1 are arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap