External coating drying system of non-stick pan production line

A technology of drying system and production line, which is applied to the coating, the device for coating liquid on the surface, and the pretreatment surface, etc. It can solve the problems of large airflow loss, low efficiency, and poor drying effect of pot paint, etc., to achieve Small airflow loss, uniform heat distribution, and reduced airflow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

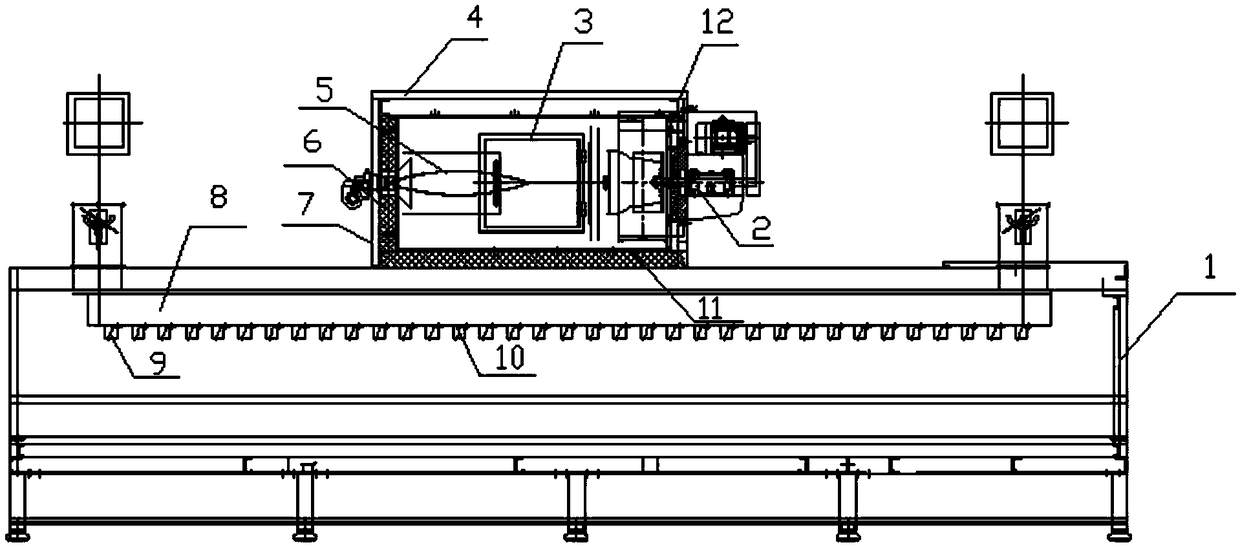

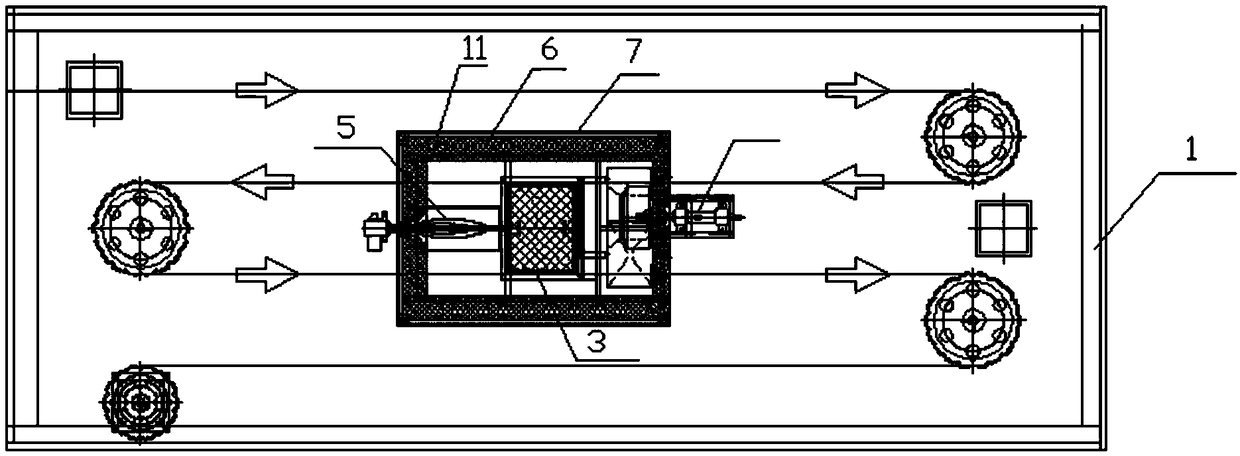

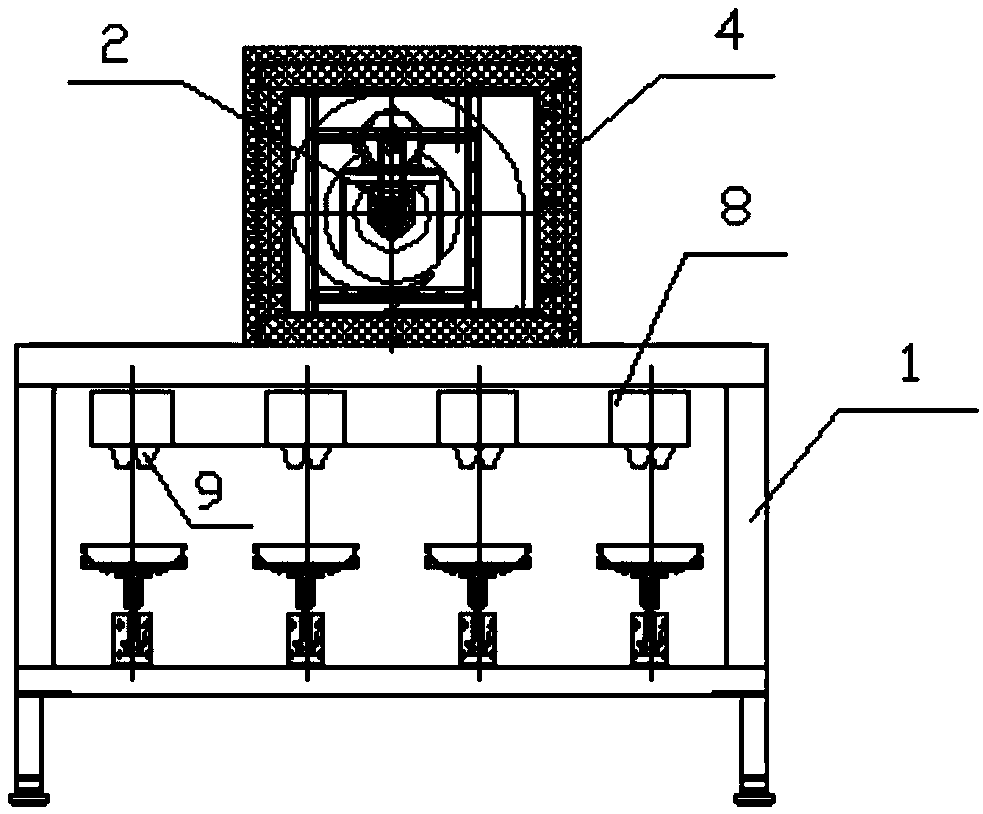

[0016] An external coating drying system for a non-stick pan production line, which includes a high-temperature fan 2, an incubator 4, an air collection chamber 8, and an external coating drying chamber 1, the incubating box is fixedly installed above the external coating drying chamber, and the The high-temperature fan is fixedly installed on one side of the incubator, and the other side of the incubator is provided with an air inlet 5. The air collecting chamber is fixedly installed on the top of the outer coating drying chamber and communicated with the incubating box. The bottom plate of the air collecting chamber is evenly distributed There are a plurality of ventilation holes 10, and a deflector 9 is arranged at the ventilation hole, and the deflector is integrally formed with the gas-collecting cavity.

[0017] Further, the deflector is in the shape of an inverted cone.

[0018] Further, the air inlet is a streamlined structure with both ends convergent.

[0019] Furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com