Electric pipe cleaning device

A technology for cleaning devices and power pipelines, applied in the field of power equipment, can solve problems such as low efficiency and poor effect, and achieve the effect of ingenious structure setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

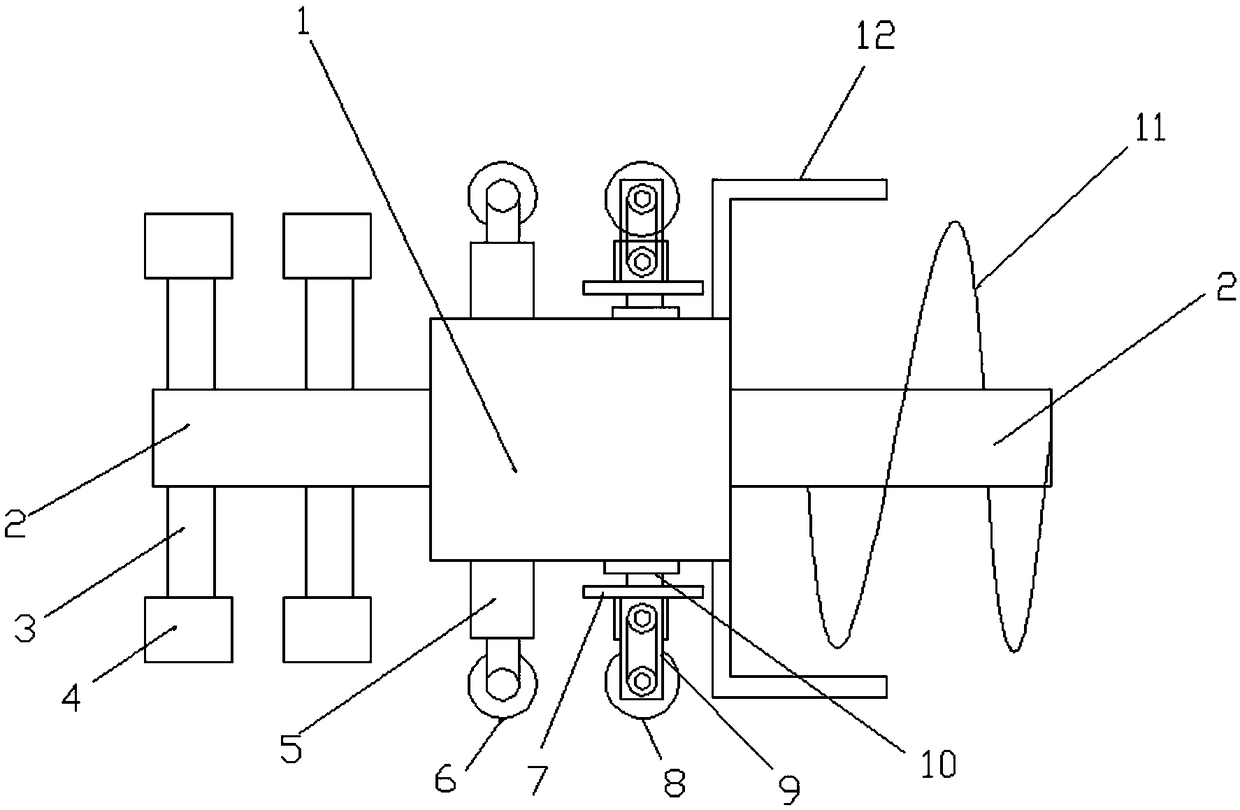

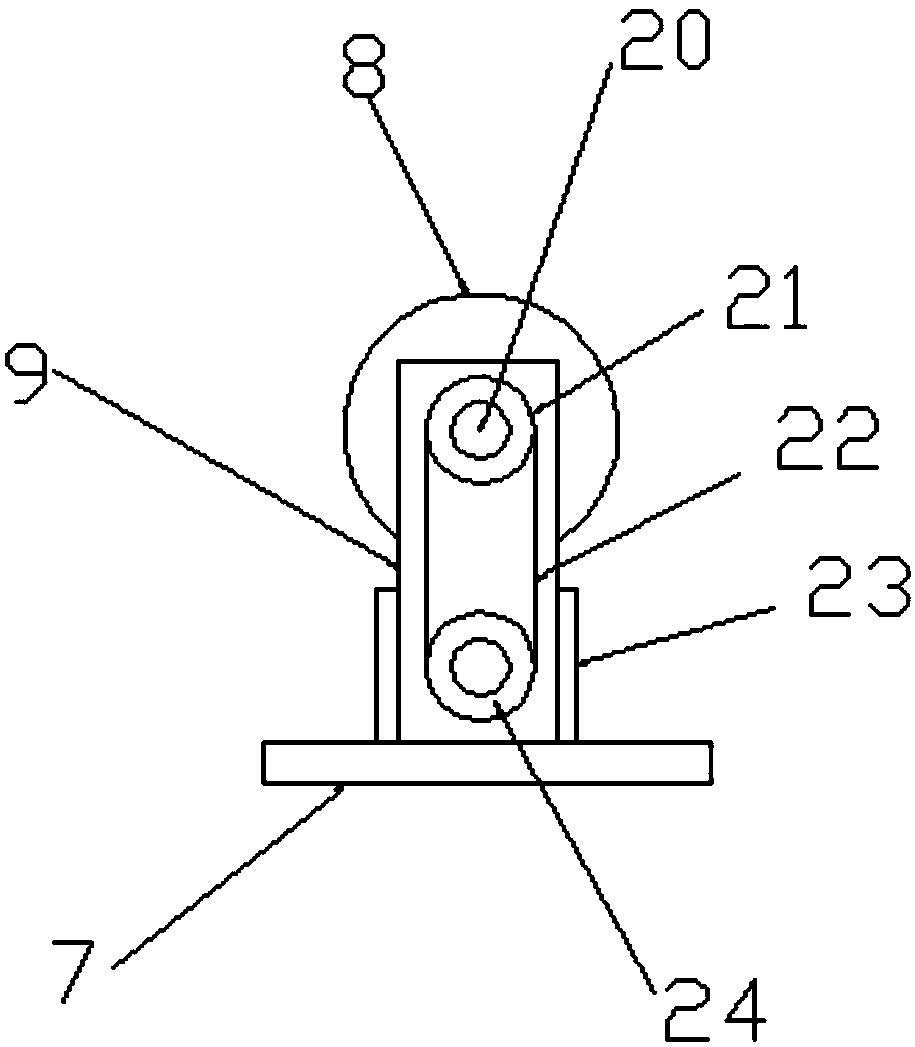

[0021] Example 1: See Figure 1~4 , in an embodiment of the present invention, a power pipeline cleaning device includes a machine compartment 1, a horizontal rotating shaft 2 runs through the machine compartment 1, and the transverse rotating shaft 2 is set on fixed bearings 13 provided at corresponding positions on both sides of the machine compartment 1, The machine compartment 1 is provided with a horizontal shaft drive mechanism, and the front side of the machine compartment 1 is evenly provided with an elastic telescopic bracket 3 on the horizontal shaft, and the outer end of the elastic telescopic bracket 3 is provided with a wiper 4. The upper and lower sides are provided with traveling mechanisms, and the rear end of the cabin 1 is provided with an aggregate storage mechanism.

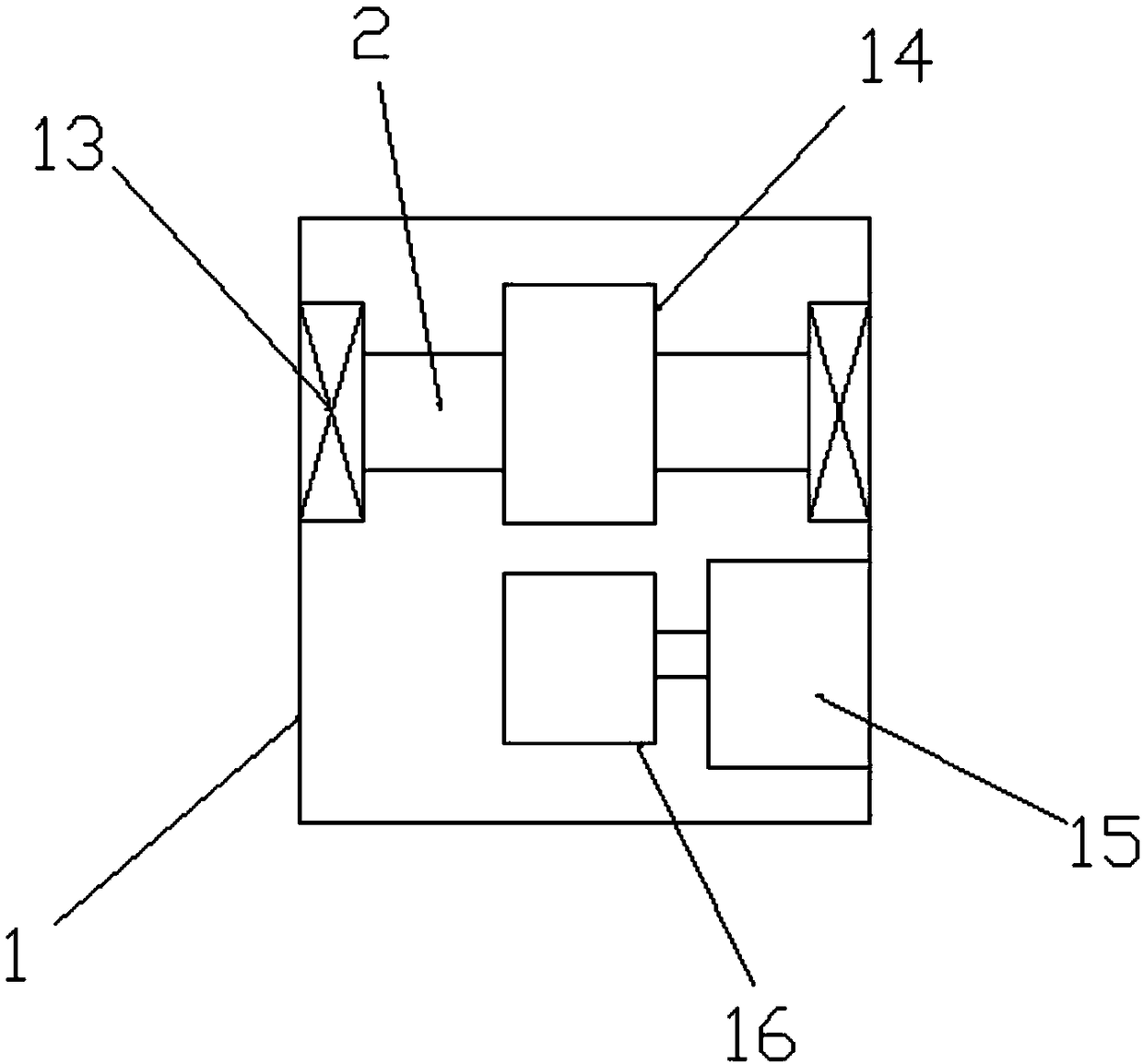

[0022] The drive mechanism of the horizontal shaft includes a driven gear 14, which is sleeved on the horizontal shaft 2 in the cabin 1, and the cabin 1 is provided with a driving gear 16 and ...

Embodiment 2

[0028] Embodiment 2: The only difference between this embodiment and Embodiment 1 is the technical feature: the cylinder 10 is replaced by an elastic telescopic bracket.

[0029] The working principle of the present invention is: the present invention provides a power pipeline cleaning device with ingenious structure and reasonable arrangement

[0030] When working, the machine compartment is placed in the power pipeline, and the scraper on the horizontal shaft abuts against the inner wall of the power pipeline under the elastic force of the telescopic spring, and the horizontal shaft is driven to clean the inner wall of the power pipeline. The cylinder drives the travel wheel to touch the inner wall of the power pipeline, and the travel wheel is driven to drive the engine compartment to move along the inner wall of the pipeline, thereby realizing the moving scraping brush cleaning, the scraper scrapes off the garbage on the inner wall of the power pipeline, and the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com