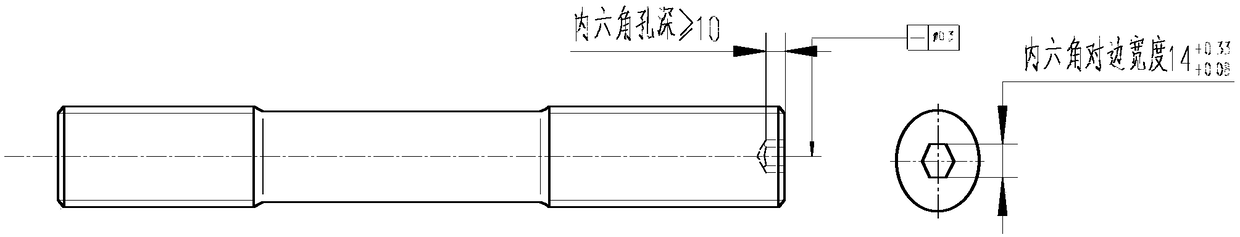

Novel shield bolt head hexagonal socket machining tool and machining technology

A shield bolt and angle processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, and cutting tools for lathes, can solve the problems of difficult control of the dimensional accuracy of the inner hexagon, low production efficiency, and high production costs, so as to avoid errors , high processing precision and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

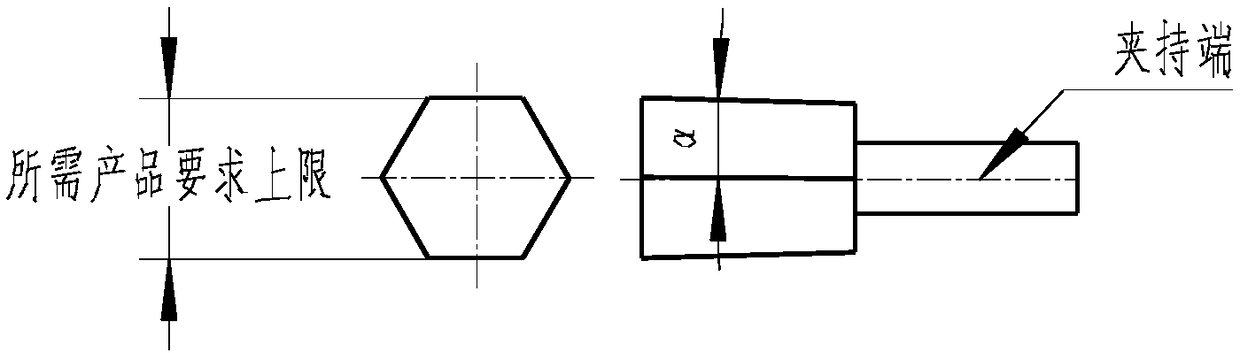

[0020] The inner hexagon forming knife 4 is made of tool steel, and its structure is as follows figure 2 As shown, its cross-sectional shape is the same as the inner hexagonal shape of the head of the shield bolt product, the size is the upper limit of the product size, and the wear limit is the lower limit of the product, and a certain angle a (the range of a angle is: 2°~3 °), in this way, the tool adopts a tapered form from the head to the tail, so as to ensure that the force-bearing area of the tool is reduced during work, and it is easy to extrude. A clamping end is provided at the tail of the tool for holding in the rotatable Morse tool handle 5 .

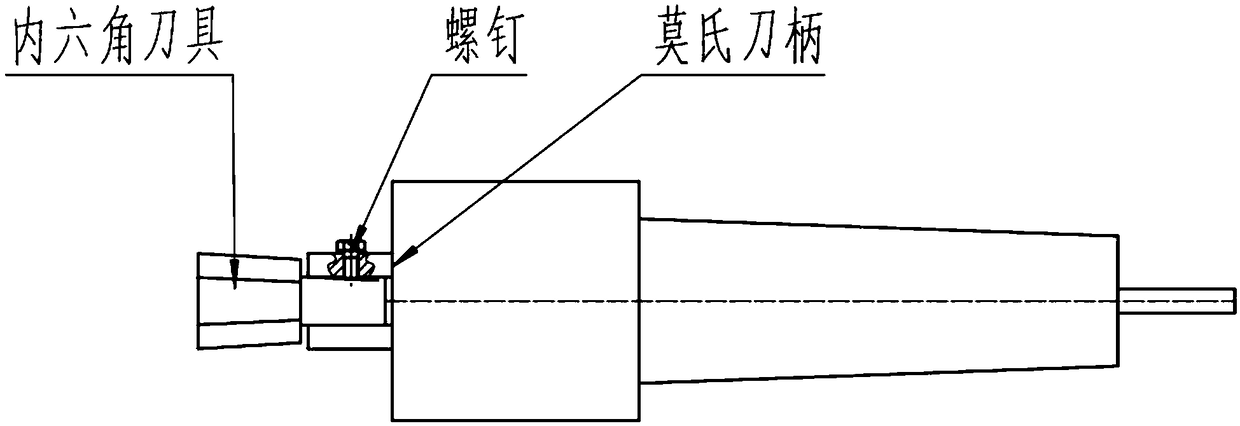

[0021] The structure of the rotatable Morse handle 5 is as image 3 As shown, one end of the rotatable Morse tool holder 5 fixes the clamping end of the inner hexagonal forming knife 4, and the other end is fixed on the lathe tailstock 6, so that the Morse taper of the Morse tool holder is connected with the lathe Morse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com