Flying shear crankshaft mechanism

A technology of flying shears and crankshafts, applied in the direction of shearing devices, shearing machine equipment, shearing machine accessories, etc., can solve the problems of low shearing strength and inability to shear high-strength sheets, and achieve strong shearing Strength, increase the applicable range, and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

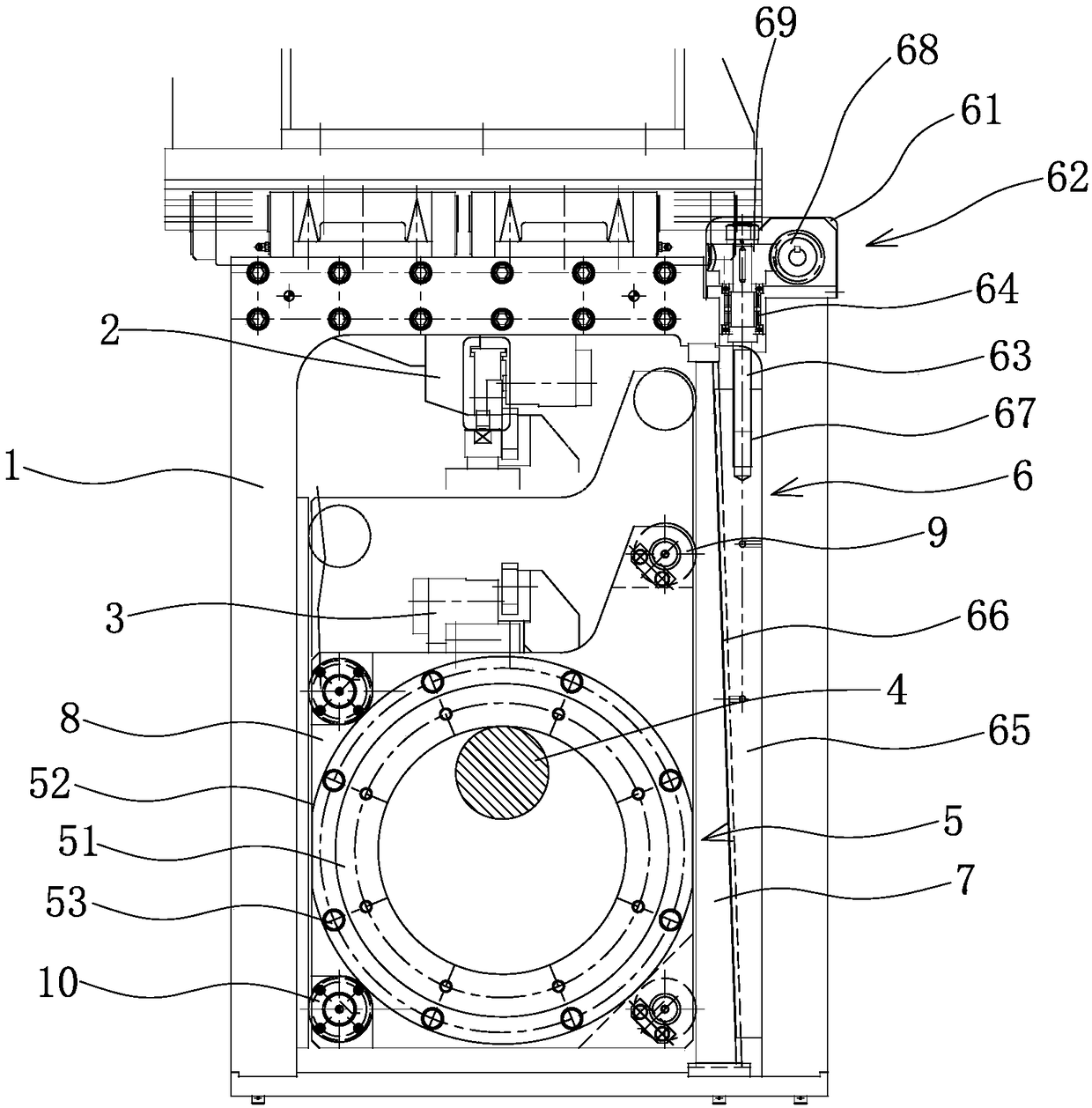

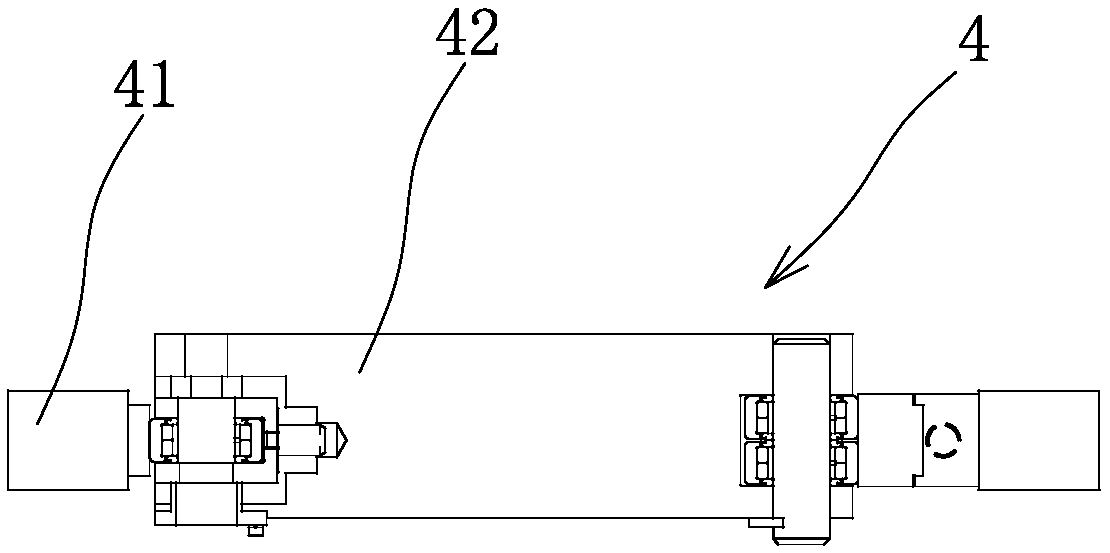

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] combine figure 1 and figure 2 Shown, a kind of flying shears crankshaft mechanism comprises frame 1, and fixed cutter 2 and sliding cutter 3 that are arranged oppositely, described fixed cutter 2 is fixedly connected with frame 1, and sliding cutter 3 is slidably connected with frame 1, Also includes a crank mechanism 4, said crank mechanism 4 is rotationally connected with the frame 1 or arranged outside the frame 1, the present invention does not limit the specific position of the crank mechanism 4, it can be rotatably connected to the frame 1, or can be set Outside the frame 1, the sliding cutter 3 is pressed on the outer surface of the push ring 5, and the inner surface of the push ring 5 is pressed on the outer surface of the crank mechanism 4. Turning the crank mechanism 4 can make the slide cutter 3 approach Or move a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com